Roof assembly frame technology. Do-it-yourself frame house: step-by-step assembly instructions with photos Roofing work for frame houses

The roof of a frame house has a fairly simple design, so you don’t even have to spend a lot of time and effort on building it yourself. Today we will try to deal with the main difficulties that may arise during the construction process. Let's give practical recommendations on choosing the type of roof, roofing material, and we will also tell you about the norms and rules, the observance of which is mandatory in the process of work.

Before starting work on installing the roof, it is worth deciding on the type of structure itself, its slope and the type of material that will be used for finishing. It is equally important to choose insulation in advance.

Types of frame house roofs

The roof of a frame house with your own hands can be: flat, single-pitched, gable, broken.

A roof is chosen not only by appearance, but also based on its features and functionality. The roof of a frame house has its advantages and disadvantages, and each type has its own.

Flat roof

The frame house with a flat roof has an unusual appearance, basically this technology is not used in private construction. Unlike other types of roofing, it requires minimal effort to construct.

Flat roof.

The main disadvantage is the need for careful maintenance. So, if snow and rain disappear from a pitched roof on their own, then on a flat structure it will stagnate and require constant maintenance. Untimely removal of wet snow can provoke a collapse of the structure; moreover, in rooms with such roofs there is increased humidity.

Shed roof

A frame house with a pitched roof is simple; the structure is not afraid of strong wind loads. Unlike a roof with two slopes, it requires a minimum of building materials and does not require special skills and knowledge for construction. The design has no drawbacks as such, but do not forget that if the slope area is too large, the snow pressure will increase.

Gable roof

The gable roof of a frame house is the most popular option in frame construction. When using this design, an additional attic space appears, in which, with proper insulation, you can organize an additional room. The load from the structure is evenly distributed along the entire perimeter of the frame house. There is no need to remove snow and water; precipitation rolls off on its own due to the corners of the slopes.

With a gable roof.

With a gable roof. broken roof

A frame house with a sloping roof is an option that is chosen when organizing an attic space. The advantages of this design include: additional space under the roof, an unusual spring appearance, low load on the house in winter. The attic roof also has its drawbacks: a lot of building materials are required for construction, poor ventilation leads to rapid destruction of the rafters, it requires special thermal insulation, otherwise all the heat from the house will escape through the roof.

Note

We recommend choosing a gable roof. It has an attractive appearance, and does not require a lot of building materials for construction. You can always buy finished projects roofs of frame houses, this will greatly facilitate the construction process.

Roof structure

Regardless of the type of roof that you decide to choose for a frame house, it is worth remembering that it has two main elements: the actual slopes and the rafters of the frame house.

Slope slope

The most optimal slope is 30-45 degrees. It not only ensures maximum durability of the roof, but also reduces the load on the entire structure from wind and snow. Roofs with a slope of 30-45 degrees are considered the safest, and in appearance they are not inferior to their competitors.

Rafters

You can calculate the rafters using a special online calculator, which is easy to find on the Internet. It allows you not only to make correct calculations, but also to significantly save time, especially for novice builders.

Rafter system.

Rafter system. The appropriate rafter section is selected depending on the following characteristics: standard wind and snow loads on the roof, which are individual for each region; the type, weight and size of the material that will be used to finish the roof; roof slope - the lower the slope, the less the load will be due to uniform distribution; the length of the rafter legs and the step with which they will be installed from each other.

The rafter system of a frame house is the frame of the entire roof, so it is necessary to pay maximum attention to the calculation of all parameters. You can choose the appropriate section yourself, or use special construction tables. The tables take into account the installation pitch of the rafters and the length of each rafter carried by the roof of the frame house (video).

Selection of roofing material

According to the step-by-step instructions for building a frame house with your own hands, on final stage During the construction of the structure, roof finishing work is being carried out. There is a huge range of roofing materials on the market; the choice depends on your needs and financial capabilities, but we advise you to follow the following rules:

- The finishing material must match the roof configuration.

- Consider the climate in the region where construction is taking place. If it often hails where you live, you should not give preference to materials that will become unusable after the first rainfall.

- The service life of the roofing material should be close to the service life of the roof itself.

- The material must meet aesthetic needs and financial capabilities. If you are a beginner, you should not choose a roofing material that is difficult to install. If you want, just involve professionals.

Roof elements

Roof elements include: the rafter system of a gable roof, roofing covering and materials used for installation.

Gable roof overhangs.

Gable roof overhangs. As mentioned above, the basis of any roof, regardless of the chosen type, is represented by a rafter structure. The frame itself is represented by a set of trusses, which are connected to each other by sheathing and ridge girder. Often they use ready-made trusses, which are installed directly during work on the roof of a frame house.

Frame houses with a roof of two slopes include the following structural elements:

- The base of the rafter structure, which is made by tying the beams, is maerlat.

- The legs of the rafters are supporting structures strengthened on the mauerlat and on the ridge girder.

- To generally strengthen the entire roof structure of a frame house, a horizontal beam is used, with which the upper part of the rafters is fastened - the wind crossbar.

- Longitudinal beams for connecting all rafters to each other.

- Lathing is a special base made of dry boards, onto which roofing material is subsequently installed.

It is not necessary to build a frame house from the foundation to the roof yourself; now some companies manufacture structural elements using an industrial method; the buyer can only assemble all the elements, like a construction set, directly on the site.

Roof insulation

Insulating the roof of a frame house is not difficult, the main thing is to comply with a number of requirements. So, it is important to choose the right size material used. This is what guarantees that the inside of the house will be cool in the summer and warm in the winter. For insulation, you can use various materials available on the modern market; most often, ordinary mineral insulation is used.

Roof insulation mineral wool.

Roof insulation mineral wool. If you are using a flat type of roof structure, it is better to use expanded clay as insulation; the material is also used to insulate the structure of a frame house between floors. When installing insulation, gaps must be created; they help avoid the accumulation of condensation due to active ventilation.

Thermal insulation materials are attached closely to the frame elements, especially for solid insulation materials: polystyrene foam or expanded polystyrene.

Tools

Before starting construction, it is necessary to prepare tools and building materials to ensure that it turns out to be of truly high quality. The list shown may vary depending on the layout of your home.

Tools for roof installation.

Tools for roof installation. - Kit measuring instruments(ruler, caliper);

- Universal tools (hammers, compressors, spray guns);

- Cutting tools;

- Tools for working with rafters;

- Nails;

- Wood set;

- Hammer;

- Roofing material;

- Insulation;

- Waterproofing material;

- Various types of sealants.

Roof installation sequence

The construction of a roof in a frame house begins with marking the bottom trim. At the next stage, the necessary calculations and verification of the parallelism of the installation of the entire structure are carried out; the last stage of preparation for the construction of the roof is the alignment of the strapping boards.

Gable roof.

Gable roof. Roof construction technology:

- Strive to ensure that the resulting roof meets as much as possible all the parameters specified in the technical documentation. Be sure to carry out additional strengthening of the structure in regions where strong winds are observed;

- The ridge beam is installed on supporting supports. It is extremely important that they are installed exactly level; you can check the correctness using a stretched construction cord;

- The length of the ridge beam starts from 11 meters, the structure itself is prefabricated, it consists of 4 boards;

- The rafters must have the same appearance and be made according to a single template;

- Take care of your own safety when working at heights;

- When working with soft tiles, an under-roofing carpet or membrane is used.

We looked at the main points that should be emphasized during the installation of the roof in a frame house. The main condition is to strictly adhere to the sequence of actions, and then no problems with installation should arise. The roof is considered one of the lightest structures, but not the roof of a frame house with your own hands; the video will help you get acquainted with all the nuances of installation and avoid making serious mistakes.

It is better to give preference to a gable roof; it is considered the most optimal option for any region. The main condition for long-term operation is the choice of suitable slope angles; it is equally important to insulate the roof well, otherwise all the heat will escape through the cracks. Thermal insulating material is laid in several layers.

Roof installation is a complex multi-step process. To assemble and install a rafter system yourself, you need to carefully study the methods of connecting elements, calculate the length of the rafters and the slope angle, and select the appropriate materials. If you don’t have the necessary experience, you shouldn’t take on complex designs. The best option for a small residential building is a do-it-yourself gable roof.

A standard roof of this type consists of the following elements:

Mauerlat is a timber laid on top of the walls along the perimeter of the building. It is secured using threaded steel rods embedded in the wall or anchor bolts. The timber must be made of coniferous wood and have a square section of 100x100 mm or 150x150 mm. The Mauerlat takes on the load from the rafters and transfers it to the external walls.

Rafter legs- these are long boards with a cross section of 50x150 mm or 100x150 mm. They are attached to each other at an angle and give the roof a triangular shape. The structure of their two rafter legs is called a truss. The number of trusses depends on the length of the house and the type of roofing. The minimum distance between them is 60 cm, the maximum is 120 cm. When calculating the pitch of the rafter legs, you should take into account not only the weight of the covering, but also the wind load, as well as the amount of snow in winter.

It is located at the highest point of the roof and most often represents a longitudinal beam connecting both slopes. The beam is supported from below by vertical posts, and the ends of the rafters are attached to the sides. Sometimes the ridge consists of two boards that are nailed to the top of the rafters on both sides and connected at a certain angle.

Racks are vertical beams with a cross section of 100x100 mm, located inside each truss and used to transfer the load from the ridge run to the load-bearing walls inside the house.

The struts are made from scraps of timber and installed at an angle between the posts and rafters. The side edges of the truss are strengthened with struts and the load-bearing capacity of the structure is increased.

Tie - a beam connecting the lower parts of the rafters, the base of the truss triangle. Together with the struts, such a beam serves to strengthen the truss and increase its resistance to loads.

A log is a long beam with a cross-section of 100x100 mm, laid along the central load-bearing wall, on which vertical posts rest. Lezhen is used when installing layered rafters when the run between the outer walls is more than 10 m.

The sheathing consists of boards or timber placed on the rafters. The sheathing can be continuous or with gaps, depending on the type of roof. It is always attached perpendicular to the direction of the rafters, most often horizontally.

If there is no more than 10 m between the external walls and there is no load-bearing wall in the middle, arrange hanging rafter system. With this system, the upper ends of adjacent rafters are sawn at an angle and connected to each other using nails, excluding the installation of racks and ridge beams. The lower ends of the rafter legs rest on the external walls. Due to the absence of racks, the attic space can be used for arranging an attic. Very often, the function of tightening is performed by floor beams. To strengthen the structure, it is recommended to install the top tie at a distance of 50 cm from the ridge.

If there is a central supporting wall, the arrangement is more justified layered rafter system. A bench is laid on the wall, support posts are attached to it, and a ridge beam is nailed to the posts. This installation method is quite economical and easier to implement. If ceilings in interior spaces are designed to different levels, racks are replaced brick wall, dividing the attic into two halves.

The roof installation process includes several stages: attaching the Mauerlat to the walls, assembling the trusses, installing the rafters on the floors, installing the ridge, and attaching the sheathing. Before assembly, all wooden elements are carefully treated with any antiseptic composition and dried in air.

To work you will need:

- timber 100x10 mm and 150x150 mm;

- boards 50x150 mm;

- boards 30 mm thick for lathing;

- roofing felt;

- metal studs;

- jigsaw and hacksaw;

- hammer;

- nails and screws;

- square and building level.

IN wooden houses The functions of the mauerlat are performed by the logs of the last row, which significantly simplifies the work process. To install the rafters, it is enough to cut grooves of the appropriate size on the inside of the logs.

IN brick houses or buildings made of blocks, installation of the Mauerlat occurs as follows:

The mauerlat bars must form a regular rectangle and be in the same horizontal plane. This will facilitate further installation of the roof and provide the structure with the necessary stability. Finally, markings are made on the beams for the rafters and grooves are cut along the thickness of the beam.

When choosing a hanging rafter system, it is necessary to assemble the trusses on the ground and then install them above the floors. First you need to draw up a drawing and calculate the length of the rafter legs and the angle of their connection. Typically, the roof slope is 35-40 degrees, but in open, heavily blown areas it is reduced to 15-20 degrees. To find out at what angle to connect the rafters, you should multiply the angle of the roof by 2.

Knowing the length of the run between external walls and the angle of connection of the rafters, you can calculate the length of the rafter legs. Most often it is 4-6 m, taking into account the eaves overhang 50-60 cm wide.

The upper ends of the rafters can be fastened in several ways: overlapping, end-to-end and “into the paw”, that is, with grooves cut out. Metal plates or bolts are used for fixation. Next, the lower and upper ties are installed, and then the finished trusses are lifted up and installed above the floors.

The outer trusses are attached first: using a plumb line, the rafters are aligned vertically, the length of the overhang is adjusted and attached to the mauerlat with bolts or steel plates. To prevent the truss from moving during installation, it is reinforced with temporary beams made of timber. After installing the outer rafters, the rest are set, keeping the same distance between them. When all the trusses are secured, take a board with a cross-section of 50x150 mm, the length of which is 20-30 cm longer than the length of the cornice, and nail it along the upper edge of the slope. The same is done on the other side of the roof.

The first option: a rectangular groove is cut out on the rafter leg at the point where it touches the mauerlat, 1/3 of the width of the beam. Stepping back 15 cm from the top of the box, a steel spike is driven into the wall. The rafter is leveled, the grooves are aligned, then a wire clamp is placed on top and the beam is pulled close to the wall. The ends of the wire are securely fastened to the crutch. The lower edges of the rafters are carefully cut with a circular saw, leaving an overhang of 50 cm.

Second option: the upper rows of walls are laid out with a stepped cornice of bricks, and the mauerlat is placed flush with the inner surface of the wall and a groove is cut out in it for the rafter. The edge of the rafter leg is cut to the level of the upper corner of the cornice. This method is simpler than others, but the overhang is too narrow.

Third option: ceiling beams extend beyond the edge outer wall by 40-50 cm, and the trusses are installed on the beams. The ends of the rafter legs are cut at an angle and rest against the beams, secured with metal plates and bolts. This method allows you to slightly increase the width of the attic space.

Installation of layered rafters

Figure 1 shows the cutting of rafter struts into a bed laid on intermediate supports, and FIG. 2 - resting the rafter leg on the mauerlat

The procedure for installing a layered rafter system:

When the main elements are fixed, the surface of the rafters is treated with fire retardants. Now you can start making the sheathing.

For the sheathing, timber 50x50 mm is suitable, as well as boards 3-4 cm thick and 12 cm wide. Waterproofing material is usually laid under the sheathing to protect the rafter system from getting wet. The waterproofing film is laid in horizontal stripes from the eaves to the roof ridge. The material is spread with an overlap of 10-15 cm, after which the joints are secured with tape. The lower edges of the film should completely cover the ends of the rafters.

It is necessary to leave a ventilation gap between the boards and the film, so first wooden slats 3-4 cm thick are stuffed onto the film, placing them along the rafters.

The next stage is covering the rafter system with boards; they are stuffed perpendicular to the slats, starting from the roof eaves. The pitch of the sheathing is affected not only by the type of roofing, but also by the angle of inclination of the slopes: the greater the angle, the greater the distance between the boards.

After completing the installation of the sheathing, they begin cladding the gables and overhangs. You can cover the gables with boards, plastic panels, clapboard, waterproof plywood or corrugated sheeting - it all depends on your financial capabilities and personal preferences. The sheathing is attached to the side of the rafters; nails or screws are used as fasteners. Overhangs are also hemmed various materials– from wood to siding.

Video - DIY gable roof

But it is unacceptable to relax at this step. Minor miscalculations will lead to the need for premature repairs, and if a serious mistake is made, the entire building may collapse. Find out what materials are suitable for the chosen project, consider the type of roof, decide whether the building needs an attic space and whether it will be used. Study the brief installation instructions to do everything yourself or supervise the work of the craftsmen.

Preparatory work

You can build the roof of a frame house with a flat roof with your own hands, but it is better not to take on more complex projects alone. Even at the stage of designing a house, it is important to think about:

- Roof shape.

- The slopes that will need to be made for the slopes.

- Roofing material.

- Device rafter system.

- The distance between the rafters and their cross-section.

- Sheathing step.

- Materials for insulation, vapor barrier, waterproofing.

Types of roofs by shape

The shape of the roof of a frame house is:

- Flat single-pitch is the cheapest and easiest to install.

- Gable - suitable for single-story and two-story houses with a small area and rectangular buildings.

- Broken line - ideal for projects with an attic.

- Four-slope - used for buildings of any type, resistant to wind loads.

- Multi-pincer - a complex structure consisting of several slopes. Suitable for multi-level house projects.

- Spire-shaped - original, ideal for snowy regions, but requires complex calculations.

When choosing a roof shape, consider:

- Area, number of floors, general project and design of the house.

- Selected roofing material.

- Climatic conditions of the region (wind, snow).

- Budget.

It should be noted that the safest is considered slope slope ranging from 30 to 45 degrees.

Basic material selection criteria

For the roof of a frame house, you can choose various roofing materials, but preference should be given to lighter ones. This rule is especially important if the foundation is not designed for heavy loads.

- bitumen shingles;

- polymer sand tiles;

- corrugated sheeting;

- slate;

- metal tiles;

- cement-sand tiles.

For heavy roofing materials, lathing should be done more frequently. Additionally, you need to use a layer of waterproofing material. It is necessary to monitor the step of fastening the main roofing material. If you do it more often, the likelihood of roof leaks can be minimized.

When installing roofing materials, it is important to adhere to the following tilt angles:

- Minimum 10 degrees for corrugated sheets.

- From 12 and 60 degrees for slate.

- For Euro slate, the lower figure is 6 degrees.

- For ceramic tiles - from 18 to 60 degrees. The same indicator should be followed when fixing polymer sand tiles.

- For bitumen shingles - more than 12 degrees.

- Metal tiles require installation at an angle of over 15 degrees.

Features of roof installation

The easiest way is to make a pitched roof with your own hands; other options will require knowledge and experience.

Roof construction includes the following stages:

- Installation of the rafter system.

- Installation of material for insulation, vapor barrier and waterproofing.

- Lathing and counter-lattice.

- Installation of roofing material.

The rafter system of the roof of a frame house must be correctly calculated. To do this, the section, pitch and the length itself are analyzed. Builders note that, first of all, the strength of the structure depends on the following parameters:

The cross-section can be selected using special construction tables or you can perform all the calculations yourself.

Installation of the rafter system

The roof of a frame house will last a long time if the ceiling beams are correctly and firmly fixed. For this, it is recommended to use timber with a section of 50 by 150 (200) mm.

At the first stage, you will need to create a special template for the rafter legs. To do this, all manipulations should be performed according to the following scheme:

- Take two boards and place them at right angles to each other. For strong fixation, ordinary nails can be used.

- The resulting element is additionally secured to one edge of the Mauerlat.

- By moving the boards, set the angle, which will later be used as a ramp.

- From the edge of the wall retreat at least 40 centimeters. The resulting space will be used for water drainage.

- After obtaining the required angle, securely fix the beam. Builders advise marking the cut line with a simple pencil.

After preparing several templates, you will need to connect two pairs of rafters together. Fastening is done on both sides. If necessary, legs can also be extended separately in the future.

Regular thick bolts are quite suitable for joining. This option is several times safer, especially when compared with fastening with nails. Between two adjacent legs you will additionally need to install a transverse fastening option.

A lean-to frame house will be protected from bad weather if all roofing elements are installed correctly. To do this, a rope is pulled between the side rafters. It will serve as a beacon and guideline against which the level is checked. Further elements are secured at a distance of 60 or 80 centimeters. This step is recommended to be followed at all times.

The calculations necessary to determine the number of rafters are made in advance. You will need to nail two boards between the individual elements of the truss. They will provide the necessary fixation. For additional protection from precipitation, you should install diffuse membrane.

The size and pitch of the sheathing can be calculated independently using formulas. In this case, it should be taken into account mandatory slope and features of a particular material. For the construction of the sheathing, it is possible to choose a beam whose cross-section is from 40 to 50 mm.

Laying roofing material

At the first stage, the cornice strip is installed. For this it is advisable to use self-tapping screws. Only after this is it allowed to lift metal tiles onto the roof. It is also secured to the cornice strip using self-tapping screws.

There are situations when one sheet is not enough. In this case, it is advisable to increase the length. To do this, the fastening is done with an overlap. All material is laid using this technology.

The video describes the installation of the roof in detail and in an accessible manner.

There are many material options for building a private house on the modern market. The most common ones are brick, block and log. But lately, frame houses have become increasingly popular. They are characterized by simple and quick installation. You can do it yourself without resorting to the help of professionals. Below you will find recommendations on how to build the roof of a frame house with your own hands.

The roof structure is heavy and rests on the load-bearing walls of the house.. In the case of a frame house, the roof is installed on vertical posts covered with OSB boards up to the middle of the top frame beam. Decorative wall cladding is done after the roof is installed. And after this, the pediment and cornice overhangs are hemmed.

They are erected and sheathed before the roof is assembled. Therefore, before starting work, you need to prepare a project where the appearance of the roof and its slope will be determined. The pediment can be attached in parallel with the installation of the roof, but first you will still have to install the outer trusses, securely secured using braces.

The roof height of a frame house is usually more than 6 meters. Before starting work, you need to decide on the type of rafter system. Depending on the width of the span to be covered, the rafters may have a ridge board, a support screed or sloped braces if there is a central load-bearing wall. If the span is small, then rafter ties are usually installed. Attic walls can act as a supporting screed.

The rafters are secured using nails, self-tapping screws, metal plates or angles. The pitch of the rafters is determined within the range of 40 - 100 centimeters. This figure depends on the cross-sectional size of the wooden beams from which the racks are made. They can be within 2.5 - 5 meters.

Wooden blocks with a cross-section of 10x10 centimeters, called mauerlats, are laid on the external load-bearing vertical posts of the wall to support the rafter legs. Required condition its settings are rigid fixation. It is best to connect the rafter legs using serrated overlays. If the overlapped span is more than five meters, it is necessary to install a special support under the rafters. After installation, the sheathing is installed to lay the roof covering. It can be made of OSB boards, plywood, edged, half-edged or unedged boards. This depends on the chosen roofing covering.

If there is an attic floor, the roof must be insulated. The insulation is placed between the rafters. Provided that its thickness is 10 - 15 cm, the cross-section of the rafters will be 15x5-15x7 cm. The cross-section of the rafters is selected according to the thickness of the insulation and the amount of snow load. To do this, calculations are made. If it is not possible to carry it out, then take a larger section of rafters. If the insulation thickness is more than 15 cm, rafters with a section of 20x7 cm are suitable.

When installing rafters on the mauerlat, a triangle equal to 1/3 of the height of the rafter is cut out in the support bar.

The roof may have one or more slopes. At the same time, a complex roof looks more interesting. But the best option, both in terms of the amount spent and the work carried out, would be a gable roof. It does not have valleys and has only one ridge, which will be a definite advantage when building a roof with your own hands, since these places in the structure are the most vulnerable.

When choosing the slope value, it is worth considering that with an indicator of less than 28 degrees, the load on the rafter system increases. This will lead to the need for strict calculation and control of load-bearing elements. And with a slope exceeding 50 degrees, wind loads increase. The optimal choice would be a slope between 35-45 degrees. Such a roof will look better, and snow will not linger on it.

Roof installation

Let's look at roof installation using the example of a house with overall dimensions of 6x8 meters, a gable roof with a slope of 45 degrees, where bitumen slate is used as a roofing covering. The design includes an attic floor with a wall height of 1.1-1.6 meters.

The height of the walls of the attic floor should not be less than 1.1 meters. This will cause inconvenience during the operation of the under-roof space. In a cold attic, there is no need to raise the walls, and the roof structure will not change.

As a rafter system we will use two inclined rafter legs connected by a crossbar to ensure rigidity. It is also called a tie, jumper, cross member, etc.

The presence of an attic floor requires. Therefore, we will choose the parameters 15x5 cm as the cross-section of the rafters. And we will take the thickness of the insulation 15 cm (according to calculations for Moscow - 138 mm).

Next you need to decide on the length of the rafters. This can be done by making calculations. First of all, you need to decide on the angle of inclination. If you don't yet know which inclination to choose, follow the instructions below

Two slats 6 meters long need to be knocked together using nails in the shape of the letter “L”. This will clearly show what the roof truss will look like. The work is carried out on the ground. After this, it is worth preparing a test crossbar. It is a long strip that is applied to the rafters to measure its length.

After this, we lift the resulting truss onto the roof and rest it on the beam of the upper frame. Next, using the selection method, we determine the angle of inclination and, accordingly, the length of the rafters. When determining this parameter, it is necessary to take into account that the overhang of the rafters relative to the wall should be 30-55 cm.

The roof overhang is made to protect the walls of the house from precipitation. If there is no drain, the overhang should be at least 50 cm.

With this method of selecting the length of the rafters, it is necessary to take into account that the final height will be 5 cm lower due to installation on the mauerlat. To make such an installation, a rectangle of 5x5-5x6 cm is cut out of the Mauerlat bar for rafters with a cross-section of 15x5 cm. And when trying on the rafters, it is necessary to mark where the support will take place and draw a vertical line. Thus, we will mark one side of the triangle, and mark the other on the ground at an angle of 90 degrees.

The pitch of the rafters is determined depending on the cross-section of the rafters and the roof slope. For the example under consideration, a step of 70-80 cm is best suited.

The next stage is preparing the required number of rafter legs. To do this, we use an already marked truss. This work should be carried out on the ground. We mark each subsequent rafter leg according to the first sample to prevent the accumulation of errors.

Then we proceed to fastening the crossbars. The best place to place them is as low as possible. The crossbar is necessary to perceive the thrust, and the lower it is, the better it works.

In the presence of an attic floor, the best mounting height for crossbars is 2.25 - 2.35 meters. This will allow for doorways with a height of 2.1 meters. When reducing the height of the openings, you can place the crossbars lower. But at the same time, the height of the premises will be correspondingly lower. To make the height of the premises equal to 2.5 meters, which is considered the most convenient parameter, the crossbars are made at an identical height of 2.5 meters.

The presence of a counter-lattice will provide a gap for ventilation in the roof. There should be two of them - a lower and an upper ventilation gap, each 2-4 cm high. This is done regardless of whether the roof is insulated.

The lower ventilation gap is made under the waterproofing layer, and the upper one is made above. They allow condensation to evaporate and prevent water accumulation. The presence of both ventilation gaps will ensure that the wooden elements do not become covered with mold or mildew.

The counter-lattice is attached to the rafters lengthwise. The pitch for them is chosen in accordance with the pitch of the rafters. The cross-section of the boards for these purposes is 2x5 cm.

Next we attach the sheathing. The size of the section and pitch will depend on the selected roofing material. According to the conditions of our example, this is . Therefore, we choose unedged boards for the sheathing with a cross-section of 4x5 cm. And we will install them in increments of 35 cm.

We select the length of the sheathing taking into account the presence of an overhang beyond the outer rafter leg of 20-50 cm. It can be equated to the overhang of the rafters.

Material selection

Undried wood (sometimes called wet wood) is suitable for roofing work.. You can buy it at the sawmill. When choosing, pay attention to appearance. If the wood is gray, this may indicate the presence of fungus. Undried wood will require less financial investment than dried wood, since its price depends on the cubic meter rather than the square meter.

After purchasing, be sure to remove the bark from the wood - this will prevent the formation of bark beetles.

After calculating the roof elements, you should order the material. It should be borne in mind that standard lengths of lumber will cost less. And you can trim them yourself, using the leftovers for something else.

In this article in the series “Do it yourself frame house” we will look at building a roof. Let's decide at what stage of construction the roof of a frame house should be done with our own hands. Let's look at how to choose the right rafters for a frame house, what roofing material to use and how to insulate the roof of a frame house. Some subtleties of roof installation will also be discussed and necessary tool for erecting the roof of a frame house.

What to look for before starting construction of a frame house roof

The roof structure is heavy, so it must rest on the finished walls of the house. Ready-made, in our case, are: vertical frame posts are installed, they are secured with constant bevels, connected with a beam of the upper trim, and sheathed on both sides with OSB. The OSB sheathing is brought to the middle of the beam of the upper trim. This frame is stable and capable of supporting the roof structure. Decorative wall cladding (external and internal) is usually done after the roof is installed. And the filing of the overhangs (pediment and cornice) is done after the walls are faced.

If the roof structure involves the presence of gables, then the gable is usually erected and sheathed with OSB sheets before assembling the roof. Therefore, it is advisable to decide on the slope of the roof before erecting the gables, since the top line of the gable depends specifically on the slope of the roof (more details about choosing the slope of the roof will be discussed in this article a little later). Or you can build the pediment parallel to the roof, but at least after installing the outer rafter trusses. The trusses are securely secured with braces.

If the floor under the roof is an attic, then in addition to the gables, low walls will also be erected on the eaves side, so they also need to be erected and covered with OSB before assembling the roof.

The section, pitch, principle and method of connecting the main elements of the pediment and these low walls are the same as the main frame of the first floor. You can read more about this in the articles:

On the top of the small walls of the attic floor, you need to lay the top trim beam on all 4 walls (i.e., on those along which the pediment is planned to be built, too). Continue to build the pediment above this trim to the required height. Upper frame beam in in this case will be the same section as the beam of the upper frame of the first floor. In the future, it will serve as a support for the rafters, i.e. perform the function of a Mauerlat.

What you need to decide before building a roof

Select roof configuration

In this article, as in the entire series of articles “Do-it-yourself frame house,” we are looking at a house with dimensions of 6x8 m.

Previously (in previous articles) we selected the following sections of frame elements:

top frame beam 100x150 mm (connects the vertical posts of the frame along the top), floor beams - 180x130 mm, pitch 600 mm.

In order to make a roof, we need to decide on the number of slopes, slope angle, roofing material, select the sections and pitch of the main roof elements (rafters, sheathing, counter-lattice). Now about each point in detail.

Number of stingrays

The more complex the roof, the more beautiful it usually looks. But at the same time it automatically becomes more expensive. The optimal number of stingrays from the point of view of beauty and cost, in our opinion, is two stingrays. One slope looks a little boring, and a 4-slope (tent or hip) will cost more. We will not disassemble the mansard (hip and half-hip) roof in this article either. Let's focus on a gable roof, which is suitable for both a cold attic and an attic floor (provided that the walls of the attic floor are at least 1.5 meters and the slope of the slopes is no more than 45°). The gable roof has only one ridge and no valleys. Which is also a plus, since the valley and ridge are the most vulnerable, and therefore the most difficult to arrange, places in the roof structure.

Choosing roofing material for a frame house roof

The roofing material determines the permissible slope of the slopes. Since each roofing material has its own recommended slope range at which this material can be laid safely. That is, it will not slide, retain snow more than it should, etc. Sometimes it is possible to lay on a greater or lesser slope than indicated in the recommended range, but with certain changes in the roof structure, such as increased waterproofing, more frequent laying of the sheathing or replacement of the sheathing with a continuous deck, more frequent fastening of the roofing material itself, etc. . I will give the permissible slopes for the most popular roofing materials:

- cement-sand and ceramic tiles - 25-60°;

- polymer sand tiles - 20-60°, a smaller angle is allowed when the sheathing is reinforced;

- bitumen shingles - from 12° (maximum slope is not limited);

- metal tiles - from 20°, a slope of 15° is allowed, provided the joints of the metal tiles are sealed;

- corrugated sheeting - from 10°;

- asbestos-cement sheets (slate) - 12-60°;

- bitumen corrugated sheet (aka Euro slate, bitumen slate, ondulin) - from 15°, a slope of 10° is allowed when reinforcing the sheathing and from 5° when replacing the sheathing with a solid flooring.

For our example, we will choose the most popular roofing covering in budget construction - bitumen slate. It is lightweight, looks good and does not cost much, which is very important for budget construction. The only thing we can say from our experience of working with this material from different manufacturers is that it fades evenly over several years. But, apart from the color (burnout), there were no complaints about this material when installed correctly.

Slope slope

A roof with a slope of up to 5 degrees is considered flat, and a roof with a slope of more than 5 degrees is considered pitched. A pitched roof with a slope of less than 28 degrees is considered loaded and more stringent requirements are imposed on its load-bearing elements. As a result, with a slope of less than 28 degrees, more powerful rafters are required, since the snow load increases significantly (snow does not slide well from the roof and almost all of it lingers on the roofing). And with a slope over 50°, wind loads increase.

Therefore, the optimal slope in terms of loads is 35-45°. This same slope also looks the most advantageous in appearance. The roof is neither sharp nor too flat. We will stop at a 45° slope.

So, on a 6x8 m house we will have a gable roof with a slope of 45 degrees, covered with bitumen slate. We will also assume that under the roof we will have a residential heated attic floor. The walls of the attic floor are raised by 1.1-1.6 m. This height depends on your comfort requirements. But 1.1 m is the minimum so that the under-roof space can be conveniently used. With such a height of the walls, under the slope in the lowest place, you can, for example, place a sleeping place or a closet. If you have a cold attic, then the roof structure will be the same, only it will not be insulated (the attic floor will be insulated) and the walls do not need to be raised by 1.1-1.6 m.

Frame house roof diagram

Now let's decide on the roofing structure diagram. Are ties, struts, crossbars, additional purlins, etc. needed? After the final determination of the scheme, it will be possible to select the sections of all elements and calculate the amount of lumber.

For a house measuring 6x8 m, a roof in the shape of the letter “A” is suitable. It consists of rafters, a crossbar (it is also called a tie, crossbar, lintel, bow, etc.).

Section of rafters of a frame house

We are considering the option of a residential attic, so our roof will be insulated. Accordingly, the cross-section of the rafters must be selected in such a way that the height of the insulation fits between the rafters. As a rule, according to calculations, from 100 to 150 mm of insulation is required in the roof (less often, more than 150 mm). Accordingly, this insulation should fit in height between the rafters.

Below I will give the calculated thickness of insulation in a pitched roof for some large cities:

Sochi - 75 mm;

Sevastopol - 109 mm;

Moscow - 138 mm;

Ekaterinburg - 140 mm;

Kyiv - 168 mm.

If, according to calculations, up to 100 mm of insulation is required, then the cross-section of the rafters can even be 100x50 mm. But for each specific case, you need to make a calculation of such a small cross-section of the rafters (whether they can withstand the snow load specifically in your region, what their pitch should be, etc.). We do this calculation. Without calculations, we recommend playing it safe a little and even with an insulation thickness of up to 100 mm, take rafters with a cross-section of 150x50 mm.

If the insulation is from 100 to 150 mm, then the rafters are 150x50 - 150x70 mm. There is no point in increasing the smaller side (50 and 70 mm) further, since a square does not carry the load as well as a rectangle. An example of this is the cross-sections of all channels and I-beams.

If the insulation is more than 150 mm, then the rafters are 200x70 mm.

For our example, we will take the cross-section of the rafters to be 150x50 mm.

Length of frame house rafters

Next I will describe one of the options for selecting the length of the rafters. This is what we use in practice. It is especially suitable if you have doubts about the slope of the future roof - you don’t know how a particular angle will look in reality.

We take 2 long slats (usually 6 meters), knock them down on one side with a nail in the shape of the letter “L”. This will be our test roof truss. We knock it down on the ground, without lifting it into place for the future roof yet.

We also prepare a test crossbar - a long strip, which we will attach to the test rafters at the required level and measure the required length of the crossbar.

We lift them onto the roof and rest our letter “L” on the beam of the upper trim. Now we try, change the angle, and the length of the rafters also changes. We select the optimal slope angle. After which you can measure the resulting length of the rafters. The length should be 30-55 cm, taking into account the overhang of the rafters “behind” the wall. We obtain a sample of the rafters.

Note. The overhang protects the walls of the house and windows from precipitation. If an organized drainage system from the roof (a drainage system in the form of gutters and pipes) is not planned to be installed at first, or for some reason it will not be installed at all, then according to the standards, the overhang should be at least 50 cm. Although an overhang of 50 cm is not bad to do even with the presence of a drainage system - it looks very good and will better protect your walls.

The only thing, when choosing the length of the rafters in this way, you need to take into account that after installation they will “sit” 5 cm lower on the Mauerlat. Since the rafters are necessarily cut into the Mauerlat for greater stability of the connection. In each rafter, at the point where it rests on the mauerlat, a triangle is cut out with approximate dimensions of 5x5 - 5x6 cm with a rafter cross-section of 150x50 cm. If your cross-section is different, then the side of such a triangle will be approximately equal to 1/3 of the height of the rafter. This placement of the rafters does not in any way affect the selection of the roof slope angle and the length of the rafters. Just visually, after installation, the rafters will be lower by about 5 cm. Plus, when trying on the rafters, you need to mark on the underside of the rafters the place where the rafters rest on the mauerlat and draw a vertical line upward from it. This will be one of the sides of our triangle. The second can be completed on the ground, at an angle of 90 degrees to the first.

At the same stage, the length of the crossbar is measured, which will be discussed in more detail below.

Frame house rafter pitch

The pitch of the rafters depends on their cross-section, as well as on the size and slope of the slopes. As you understand, there are a lot of options for different combinations of these parameters, so I cannot describe all possible rafter spacing options for their different sections, slopes and slope sizes. In our example, the rafters have a cross-section of 150x50 mm, the house is 6x8 m, the slope is 45 degrees. And for this option, the appropriate rafter pitch is 70-80 cm. If you have approximately the same parameters, then a pitch of 70-80 cm will also suit you. If the parameters are different, then ask and we will select a pitch specifically for your case.

Note. Sometimes it is recommended for insulated roofs to make the rafter spacing equal to 60 cm, since the width of the insulation roll is usually exactly 60 cm and then the insulation will not have to be cut. We do not recommend adjusting to the insulation, since by reducing the pitch of the rafters, you will increase their number and may end up with, for example, 18 rafters instead of 12. This will significantly make the roof structure heavier. Extra load on walls and foundation. The insulation is easy to cut and can be cut to the required rafter spacing without much difficulty.

We have already discussed how to determine the cross-section of the rafters, their length, pitch and the size of the support cutout (triangle) for supporting the rafters on the mauerlat. We also discussed how to prepare a sample of rafters.

Now we apply the rafter sample (already on the ground) to the bars prepared for the rest of the rafters, try it on, mark it and cut it to the required length. And so we immediately prepare the required number of rafters for the entire roof.

Note. There must be one sample and each subsequent rafter must be measured according to the first (and only) sample. If you measure the second rafter according to the first, the third - according to the second, the fourth - according to the third, etc., then the error will accumulate and by the end it will be unacceptably large. For example, even if each rafter is only 2 mm shorter/longer than the previous one, then with a number of 10 rafters the error will be 2 cm. That is, the length of the first and last rafters will differ by 2 cm.

Rigel

The crossbar should be placed as low as possible, but not lower than the planned ceiling of the first floor. The lower the crossbar is located, the better it accepts the thrust, and if you fix the crossbar high, it will not perform its function. Let's select the minimum height of the crossbar for our example. 2.1m height only entrance doors(if the crossbar is lower, the doors will no longer fit). Plus about 10-20 cm (0.1 - 0.2 m) above the door and another about 5 cm (0.05 m) for the ceiling finishing material. In total we get 2.25-2.35 m. This is the minimum distance from the crossbar to the top of the finished floor with a door height of 2.1 m. If you find doors with a height of 2.0 m, then the crossbar can be placed even lower, at a height of 2.15- 2.25 m from the top of the finished floor. It is also important to remember that the smaller the cubic capacity of air in the attic room, the less heat will need to be spent on heating it. This can also be attributed to the advantages of low placement of the crossbar.

According to standards, of course, the ceiling height in residential premises should be at least 2.5 m. But for bedrooms 2.15-2.35 m is quite suitable, of course, provided that your height allows it :-).

We take the cross-bar with a cross-section of 50x150 mm. Those. the same section as the rafters. This way we avoid confusion when ordering wood at the sawmill, and in the case of leftover rafters, we can use them for crossbars.

The pitch of the crossbar is the same as the pitch of the rafters. Those. in our case - 70-80 cm.

Counter-lattice

It provides an upper ventilation gap in the roof structure. Whether the roof is insulated or not, it must have waterproofing installed and 2 ventilation gaps, each 2-4 cm high:

- lower ventilation gap - under the waterproofing (to ventilate condensation that can accumulate on the inner surface of the waterproofing when the humidity in the room increases). You can see more details about the bottom gap in

B1 in English what level?

B1 in English what level? Managing verbs in German - German online - Start Deutsch

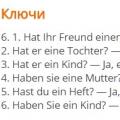

Managing verbs in German - German online - Start Deutsch Conjugation of the verb haben (to have) in the present tense

Conjugation of the verb haben (to have) in the present tense