How to build a basement under your house with your own hands. How to build a basement. Design, selection of design and materials. Earthworks. Base plate and walls. Waterproofing and insulation How to properly build a basement under a house

A cellar is an appropriately equipped recess in the ground that can be built on a site near a house, in a garage or in a basement. I believe that entering the underground storage facility from home is the best option. The cellar in the courtyard of the house needs to be insulated and heavily waterproofed, and this is an expensive and labor-intensive process. I built a cellar under the house with my own hands, digging a pit in the basement, the whole process took one summer, the construction was inexpensive in terms of money - about 10,000 rubles for everything.

The depth of the cellar and the choice of flooring material depend on the level groundwater on your site. It is better to build in dry weather in the summer, when the water does not rise high.

How to build a cellar in the basement of a private house

Before starting work, think about where and how you will remove the excavated soil. If you provide a cellar at the stage of building a house, these problems will not affect you. You should also remember about the strength of the building, so dig the pit as close to the center of the house as possible, otherwise the foundation may sag.

The exception is a foundation on piles, which cannot be damaged because the load will be on the deep layers of the soil.

Digging a pit

The height of the cellar should be sufficient so as not to bend to death in it. Dig an oblong pit to comfortably accommodate the stairs, and a little more than the planned area, taking into account waterproofing. You can dig the hole yourself or hire a digger, as digging is more difficult than it might seem.

When preparatory work will be completed, you can move on to arranging the cellar.

Filling the floor

We will concrete the floor. Concrete does not protect the room from moisture 100%, but it best solution for independent implementation. The concrete coating will not allow anaerobic bacteria, rodents and other pests to enter the room, and during high water there will be no standing water in the cellar.

- Level the bottom of the pit.

- Add a 20cm layer of sand and compact it until the surface becomes hard.

- We lay a layer of gravel on top, compact it and level it.

- We overlap the roofing felt on the finished pillow. This must be done so that water does not seep out from below, and the concrete does not soak into the soil when pouring.

- For reliability, we reinforce the floor with rods with a diameter of more than 5 mm.

- Pour 10 cm of concrete and let it dry. For complete hardening, at least three to four weeks should pass; during this time, do not lower yourself into the pit so as not to disturb the coating.

Covering the walls

The walls can be made of brick, foam blocks or reinforced concrete. I chose concrete grade M200, you can use a more durable material. Arranging a cellar with reinforced concrete walls:

- We install a mesh of reinforcement. It is best to take special rods with a cross section of 10-15 mm. If there is no suitable fittings, you can connect two thin rods or take pipe scraps. We connect the rods into a mesh with wire.

- For vertical formwork we use available materials: sheets of plywood, chipboard, slab, etc. If there is nothing to make formwork for the entire perimeter, the boards can be moved as work on the wall section is completed.

- You can add a little mortar and crushed stone to the concrete. Pour the concrete in layers of 20-30 cm, compact it and let it harden. The height of the wall should reach the ceiling.

Making an overlap

It is easier to make a ceiling for a cellar in a house than for one located in the yard, but you cannot do without it. The purpose of the ceiling in our case is to protect against heat, since the temperature in the cellar must be maintained at up to +5 degrees. After installing the stairs and planning the entrance to the cellar, we will make a wooden floor.

- We install beams on the floor and lay boards on them. Securely attach with nails or self-tapping screws.

- We lay a film on the boards for waterproofing.

- Cover the entire surface thoroughly mineral wool or glass wool.

- We overlap the thermal insulation layer with a roll of waterproofing material. We seal the seams with construction tape.

- We lay the covering that will be directly under the floor.

- The top layer is the same as the floor in the room where you dug the pit. I installed a cellar in the basement, so I covered the floor with linoleum, leaving room for a hatch.

How to avoid dampness

Even the best waterproofing will not protect the cellar from dampness with a full guarantee. Condensation may form on the walls due to the proximity of groundwater, and vegetables also release moisture.

Ventilation is not difficult to arrange - for a large cellar you will need two pipes, for a small one one is enough. Any pipes will do; I used PVC sewer pipes. The area of my cellar is only 5 sq.m. I made do with one outlet for air supply and exhaust. For a large cellar, it is advisable to equip more serious ventilation with forced pumping of air from the underground.

It is advisable to install the hood on the roof of the house, and place the lower part of the pipe under the ceiling of the cellar. The pipe for air entering the room should be at a height of up to 30 cm from the floor, with the other end out of the nearest window. To prevent insects and debris from getting into the supply pipe, install a mesh on it. It is advisable to equip the hood with a deflector to enhance draft.

Instead of a conclusion

As you can see, building a basement with your own hands is not at all difficult. The main thing is to find the right time and finish the job!

- Date: 05/23/2014

- Views: 1190

- Comments:

- Rating: 20

How to build a basement under your house with your own hands

Even if the basement cannot be called an integral part of any home, it is still a very important part. In the spacious basement you can equip a whole warehouse for storing canned and raw foods, any things and accessories that are in at the moment not needed, but will be needed in the future.

To construct a basement under the house, it is necessary to dig a pit with a depth of at least 2.1 m, and if it is planned to place a boiler room in the basement, then the depth should reach 2.5 m.

The basement can even be used as a gym or office. In order for the basement to become a truly useful structure, and not lead to the rapid destruction of the foundation of the house, you need to know the basic rules of its construction. This guide will help you do it yourself, saving money on third-party services.

Assessing the possibility of building a basement under the house with your own hands

Before you start, you need to check whether the soil is suitable, namely, how saturated it is with moisture and how close to the surface the groundwater passes. To understand everything accurately, you need to invite hydrogeologists. They will conduct relevant research, take soil samples, analyze and give a detailed answer. But in most cases, even the naked eye is enough to draw the correct conclusion. For example, it is necessary to refuse in a house built on wetlands or wetlands that are flooded during spring floods and rains.

You can check the possibility yourself: in dry weather, dig a narrow hole about 2.5 m deep and wait a few days. If the hole does not fill with water, you can start digging a pit.

Any professional builder will tell you that it is necessary to plan a basement in a house at the building design stage. This approach will significantly reduce costs and also reduce labor costs. It is good to have a basement in a private house, first of all, because it allows you to get additional meters of space that you can use at your discretion.

The basement in a house can be built in different ways. With a strip foundation, the basement will fully replicate the layout of the first floor. it can also be arbitrary, however, it is recommended to make it no less than 180-220 cm. With a high basement ceiling, it will be possible to make a living space from it, which in its characteristics will not be inferior to any room on the upper floors.

In addition, you should not completely bury the basement walls. 100-120 cm should be left above the ground. The height above the ground can be used for installing windows and ventilation system for the ground floor. If the basement is buried more than 150 cm, then the risk of flooding of the room during seasonal floods increases exponentially.

The construction of the basement must be carried out under the supervision of specialists. Especially if the underground room is planned to be built in an already finished house.

Construction method with preliminary digging of a pit

Before making a basement, you need to dig a foundation pit for it, that is, a hole that will exceed the dimensions of the basement by 30-50 cm on all sides. A sand and crushed stone cushion consisting of several successive layers of these materials is laid at the bottom of the excavated pit. Next, a reinforced concrete slab is installed. This slab will act as the foundation of the entire building.

Digging a pit using an excavator.

The upper part of this slab must be insulated from moisture penetration using rolled roofing felt (laying 2-3 layers is recommended for reliability). Next, a new concrete layer should be poured on top of the roofing felt, which will act as a base for constructing the walls of the basement.

Bricks, foam concrete blocks and other suitable building materials can be used to build walls. It depends on the design of your home. As soon as the construction of the walls is completed, they must be isolated from water penetration from the outside. For this, various waterproofing materials are used: roll insulators, bitumen mastics, etc.

Next, the basement is covered. As a rule, a monolithic slab is installed. Of course, at this stage other materials are also used for flooring (wood, concrete beams, etc.). Finally, the free cavities between the walls are filled with earth (with gravel).

It should be noted that this principle of basement construction has negative aspects:

- Construction requires the use of special equipment, which is often simply impossible in some areas located far from the city.

- Construction must proceed fairly quickly, because there is some risk that the walls of the pit will begin to crumble or float when the process is delayed.

- Brick and block walls cannot be called 100% airtight, because small cracks will form at the joints of the material, through which moisture penetrates;

- The installation of an effective waterproofing layer requires serious financial costs.

If you have chosen this technology to build a basement under your house with your own hands, then you need to take into account the fact that you won’t be able to do everything yourself - you will have to hire equipment and builders, which will lead to significant costs.

Method of pouring reinforced concrete walls into the ground

When using this technology, it is necessary to dig trenches in place of the basement walls, which are the parts strip foundation. Their depth should be 150-200 meters, and their width should be 40-60 cm. If the basement of the building is reinforced concrete, then formwork must be installed above the ground level; if the base is supposed to be made of other materials, then no formwork is required.

Prepared trench.

Reinforcement is placed in the dug trench, after which it is poured cement mortar. The result is a wall without a waterproofing layer, but its thickness provides a minimum level of hygroscopicity, so for groundwater this is a serious obstacle, but not impassable.

If you have chosen such a basement device, it will be correct to carry out drainage work. In this case, water coming from various sources will simply flow down the walls of the basement, going into the drainage channels. If concrete walls remain under constant influence of water for a long time and they do not have a waterproofing layer, then they will not be able to be used for a long time.

After the concrete has hardened, subsequent work can begin. In cases where the ceilings of the basement are supposed to be cast right there, it is necessary to install formwork, carry out reinforcement and install stiffeners.

Next, soil is excavated from the future basement to the level of its base. At the walls, the soil is slightly excavated under the walls (about ½ of their thickness). A sand cushion and gravel are laid at the bottom, after which the base of the basement is reinforced and cast with cement mortar.

Scheme of pouring concrete into a trench using waterproofing.

One of the main disadvantages of using this technology is digging a trench, reinforcing it and filling it with cement mortar. It is not always possible to correctly lay the reinforcement with your own hands, so it makes sense to hire workers for this purpose. All work must be completed quickly enough. The rest can be done with your own hands without the involvement of specialists.

Construction of a basement in an already finished house

It is quite difficult to make a basement in a cottage that has already been built earlier with your own hands. The construction of such premises must be carried out by professionals. The construction of a basement in the case of an already finished house must be motivated by something, because this is a very expensive undertaking. It should also be said that it is not so easy to make a basement in a finished house correctly. Even many contractors say that “we don’t do that.” This is due to the high labor intensity of the work. But, however, nothing is impossible.

In most cases, the cost of laying the foundation of a standard country house is about 20% of the total financial investment. If the foundation needs to be rebuilt (for example, to make a basement), the costs will increase by 2-3 times. That is why it is necessary to approach the issue of building a basement in an already finished house as responsibly as possible. In this case, experts recommend making a basement under part of the house, and not under the entire first floor. Economically it is more profitable. When choosing this technology, construction will proceed differently. The basement walls will not be connected to the walls in the house.

The following technology can be chosen: first of all, soil is removed to a depth of 150 cm along the perimeter of the walls of one of the premises of the house (for example, the kitchen). The floor and walls of the future underground structure are reinforced with asbestos cement sheets. Waterproofing is placed on these slabs in several layers. Finally, a reinforced concrete floor about 20 cm thick is poured, and small-width concrete walls with additional reinforcement are installed around the perimeter of the room.

Taking into account the fact that the thickness of the walls is small, it is necessary to install high-quality waterproofing. In general, any basement construction should be carried out taking into account the installation of a highly effective waterproofing layer, because underground rooms are most susceptible to moisture (ground and sedimentary water).

An option for installing a basement under part of the house.

Ventilation issue

Ventilation of basements is carried out, as a rule, using ventilation ducts. Ventilation ducts are made from brickwork with a certain cross-section or from other suitable materials (corrugations, plastic pipes etc.).

The exhaust pipe is installed under the basement ceiling. Its upper part should extend onto the roof of the house and be located as high as possible. To improve the draft of the basement exhaust pipe, it is necessary to lay it in close proximity to the smoke ducts (for example, the duct of a heating boiler). The upper part of the supply pipe can be placed in the attic, and the lower part - under the basement floor. During the summer months it is often natural traction not enough, so many homeowners install a fan in the exhaust pipe.

In addition to ventilation ducts, ventilation of the basement can be done using vents, which can be presented in the form of small windows located in the basement wall. High humidity is eliminated by ventilation.

Blind area device

The blind area is the first barrier to the penetration of melt and rain water into the house. If there is no blind area around the country house, then during rains moisture will gradually seep to the walls of the room, after which it will penetrate into the basement through the capillaries in the building material. Due to constant exposure to moisture, the material will begin to quickly deteriorate (especially in winter, when water freezes and expands).

Do-it-yourself blind area construction is done using various materials: monolithic concrete, slabs, cobblestones, bricks, asphalt, etc. Its width will depend on the soil and the length of the cornice. In the standard version it is 50-100 cm.

IN country house doing it yourself is a rather complicated and responsible task. In 95% of cases, it will not be possible to do without the help of specialists who can professionally make waterproofing and thermal insulation layers.

It is worth noting that making basements in already constructed buildings is not recommended, because this will cause high construction costs. In addition, the risks of damage to the building’s foundation will increase, especially if the construction of basements is done by hand.

If you decide to build everything yourself, then be sure to enlist support. Even banal advice from neighbors who have already built basements in their houses and know everything about the groundwater level and the features of the area will help. Whenever possible, the construction of a basement should be carried out by hiring specialists.

- Date: 05/30/2014

- Views: 705

- Comments:

- Rating: 47

Principle of basement construction

How to solve the problem of lack of usable space?

Every zealous owner faces the task of building a basement. It is impossible to imagine a residential building without an underground space. And the opinion that this element in the design of a house is intended only for storing unnecessary things is deeply mistaken. When building a basement it is decided current problem with a lack of usable space, but other purposes may also be pursued.

If the basement will be used as a cellar, then the depth of the pit should be at least 1.5-2 meters.

For example, the construction of a cellar will provide seven fruits and vegetables in the winter. Although in this case you will have to give up heating the underground space, which is not very good for the foundation. However, as a technical room it will provide an opportunity to get rid of massive household appliances in the kitchen or bathroom and use the freed up space.

There are several methods. The difference between them is only in the order of construction of the constituent elements of the foundation. The construction principle does not change.

A full-fledged basement is built on a strip foundation, which will also serve as the walls of the basement.

Such a foundation is installed on a tile base, this gives the structure the necessary strength and rigidity. To save money building material, you can build a strip foundation and pour concrete on the floors in the basement of the house only between the walls. In this case, it is necessary to use reinforcement and create proper waterproofing.

Before you begin construction, you need to purchase the following tools:

- bayonet shovel;

- shovel;

- axe;

- bucket;

- tamper;

- concrete mixer;

- hacksaw for metal;

- plane;

- hammer;

- trowel;

- furnace hammer;

- hacksaw;

- hammer-sledgehammer.

Return to contents

Basement construction technology

The construction of a basement begins with digging a pit for the foundation of the future house, thus freeing up space for the basement. The pit size should be more sizes future home by 1-1.5 m. The depth of the pit must be calculated based on the fact that there should be room for free movement in the basement. If the groundwater level does not allow deepening to the required amount, the foundation walls must be located at the required distance above the ground. Consequently, the base will be more massive.

Then the bottom of the pit is filled up gravel-sand mixture and compacted, and a reinforced concrete layer is laid on it. After this, waterproofing should be carried out using roofing felt or other similar material. Next, thermal insulation is laid and another concrete screed is installed on top of it.

At the next stage, the construction of walls begins. If the basement has technical functions, then the maximum height of the walls should be 1.9-2.2 m, and if a living space is intended, then the recommended height is 2.6 m.

When constructing a monolithic basement in a house, the walls are arranged in accordance with strip foundation technology. To do this, trenches are dug, sand is poured onto the bottom and formwork is installed. After waterproofing measures, reinforcing mesh is laid and concrete is poured.

If the floor is poured first, then the formwork to form the walls is installed only after the concrete has completely hardened. Since, under the weight of the concrete solution, the formwork braces can easily be pressed into the floor and form unnecessary depressions.

Return to contents

What kind of walls can be made in the basement?

Concrete is an excellent material, but if you need one hundred percent confidence in the strength of the building, you should give preference to brick walls. Of course, such work requires extreme accuracy, you need to monitor the verticality and horizontality of the walls, but the end result is worth it.

You need to start laying from the corner and work up to the 7th row. When applying plaster, it is necessary to ensure that the solution does not get on the internal surfaces.

Experts advise laying reinforcing mesh every 0.5 cm. This is required so that the structure gains additional strength. To completely cover the frame with cement mortar, you need to increase the thickness of the plaster layer by 2 cm.

Don't forget about window and door openings. Jumpers can be made of either wood or reinforced concrete. Wooden ones should be made of beams with a cross-section of 15 cm. They are pre-treated with bitumen and laid on each side at a distance of 25 cm. Reinforced concrete lintels are mounted in reinforced formwork, the width corresponding to the walls. The diameter of the reinforcement should be 7-8 mm.

Another way to build walls is to use blocks. It attracts with its simplicity of the process and time savings: a basement made of blocks is built very quickly. You just have to align each block vertically, horizontally and wall level. If you start laying from the corners, the process will not seem tedious. When designing load-bearing columns, it is recommended to fill them with concrete mortar in accordance with columnar foundation technology.

Of course, when high level groundwater, it is better to build a reinforced concrete basement. The most reliable concrete in this regard is M500.

The order of work also depends on the height of groundwater flow. If they are located too close to the surface, the first step is to form the floor, and if there is no groundwater, you can start construction from the walls.

Return to contents

Preparatory work and technology for pouring a concrete floor

The floor is that element of any room that requires a competent and careful approach during construction. Since the basement is the main load-bearing structure, the durability of the building itself depends on its quality execution. And therefore, every little thing and even an inconspicuous detail is important here.

For the house you need to do the following work step by step:

- Prepare the base.

- Pour concrete.

- Make the screed with concrete.

- Mount the supports.

- Install the floor.

First you need to clear the base of vegetation. This process can be accelerated if you remove a layer of soil 20 cm thick. Sometimes experts recommend removing a layer of soil 50 cm thick and then filling the bottom of the basement with coarse sand. In both cases, the bottom should be compacted tightly. After completing this procedure, you can begin preparing the subfloor for concreting.

You need to make marks on the walls at the desired level and then stretch a cord or thread between them. Then a layer of crushed stone or gravel 10 cm thick is poured onto the bottom. In order to distribute the bedding evenly, wooden pegs 10 cm high are driven in every m on the floor.

Now you need to pour a 50 cm thick layer of coarse sand onto the crushed stone and compact it. A plastic film with a thickness of at least 0.25 mm and an area slightly larger than the floor area is laid on top.

At the next stage, the concrete mixture is prepared. To do this, mix cement, sand and crushed stone in a ratio of 1:2:3. You can also use ready-mix concrete M300. To determine the amount of concrete, the floor area is multiplied by the thickness of the concrete mixture layer. To install a floor in the basement, the required layer of concrete is 10 cm.

Before starting work, the floor surface should be divided into strips about 1 m wide using wooden slats. The upper part of the slats is installed at the level previously indicated by the stretched rope. The solution is laid out in stages, guided by the installed slats.

We will tell you briefly and clearly about the construction of a garage with a basement. You have been waiting for this moment for a very long time, and now it has happened! There's a brand new, shiny car sitting in your yard. But then the question of storing it arises.

Of course, it is best to take care of this in advance.

Best build a garage with a basement, and it’s also worth equipping it with a small workshop. The garage can be built from cinder block, brick, or use corrugated sheeting. The latter method is not entirely suitable for long-term storage of a car, since in such a room the metal is subject to severe corrosion.

So we will take brick construction as a basis.

As with all other construction, an important aspect is to carefully consider the design of the building and its components.

We will build a garage with a basement. It should be absolutely clear to everyone that an additional room will significantly save space in the already limited garage area. It is advisable to think through all this in advance, since in a ready-made garage, building a basement can be quite difficult. We can select the most optimal foundation option, think through the ventilation and waterproofing system.

It is worth carefully studying the characteristics of the soil on which your premises will be built. To build a garage with a basement, you will need to go deeper by about 2-3.5 meters.

So, foundation. Most often for building a garage with a basement A strip foundation system is used. This will also allow you to use part of the foundation as basement walls. If the soil has sufficiently high moisture content, it is advisable to build the cellar from monolithic concrete.

He has higher density Unlike tape, it is also more waterproof.

To build the foundation we will need to dig a pit. Its depth should be at least 30 centimeters deeper than the planned basement floor. With independent construction of a garage with a basement you can significantly save money by reducing the area where the foundation is laid, since you can deepen the pit only in that part of it where the basement itself is planned.

Of course, for these purposes it is best to use special equipment, but if you do not have strong physical strength, you have a crowbar, bayonet and shovel shovels, and for a number of reasons you want to do all the work yourself, then go into battle!

We mark the future foundation on the ground using a tape measure. The horizontal level is drawn using a hydraulic or laser level. We form a sand cushion into the finished pit and compact it evenly, adding a small amount of water, and then lay the formwork.

Formwork can be made from boards and plywood.

DIY cellar under the house

Try to fit the boards tightly together to avoid excessive leakage of concrete mortar into the resulting cracks. Do not forget to lay asbestos-cement or plastic pipes for ventilation. They should also be insulated if necessary. For this you can use glass wool or polystyrene foam.

IN construction of a garage with a basement Keep in mind that the basement room must be well ventilated, do not forget to provide a ventilation system.

We pour the ready-made concrete solution into the prepared formwork, distributing it evenly over the entire area of the foundation. It is advisable to carry out this operation at a time, i.e.

don't put it off until tomorrow. The finished foundation must stand for at least two weeks. For the basement itself, the best would be a reinforced concrete floor, but clay or wooden floor options are also possible. After this, it is imperative to waterproof the prepared basement area.

To do this, the walls are spilled with heated liquid bitumen. Only after this can you begin laying the floor of the future garage.

For building a garage with a basement, the floor can be formed using a reinforced concrete slab. To do this, you can use ready-made floor slabs, or make everything yourself.

If you decide to fill the floors yourself, you will need to make formwork for the future floor. Using boards or plywood we form the area of the future floors. We install supports from wooden or iron posts at the bottom of the finished flooring. From the reinforcement we lay out a mesh with a cell of 20-25 centimeters. We twist the joints using wire or use welding.

It is necessary to make two similar layers, tearing them apart by 10-12 centimeters. We tear off the entire iron structure from the prepared formwork by about 4-5 centimeters.

And we proceed to pouring the prepared cement-sand mortar. Ideally, the finished floor slab should be at least 20 centimeters.

Garage wallswith basement We decided to build it out of brick. Yes, this is truly the ideal material for this room. The thickness of the masonry can be either a brick or one and a half.

This will probably depend most on the climatic conditions of your region. With a trowel, a level and a plumb line in your hands, you can easily erect garage walls in a short time.

For the binder, cement-sand mortar is used in proportional ratio 1 to 4-6, i.e. you need to mix 1 part cement and 4-6 parts sand. Such proportions are quite sufficient, since the load on the brick will be mainly compression, but not tensile. When laying, take into account the location of the gates and, if any, windows.

Letting down masonry walls to the roof level, it is necessary to provide grooves for the roof rafters.

To do this, leave gaps of approximately 6-7 centimeters wide and 15-20 cm high. The distance between the grooves should be approximately one meter.

Now we can proceed directly to arranging the roof. For the base, a rafter board with a section of 15 by 5 cm is used.

We distribute the timber evenly by inserting it into specially prepared grooves in the walls, while tying it together using metal staples and nails. We create the so-called overhang of the roof using rafters 20-30 centimeters from the outer boundaries of the garage wall. Now we lay the sheathing for the roof.

This can be a beam with a section of 5 by 5 centimeters or an inch beam about 10 centimeters wide. We fasten it with nails or screws. Samu garage roof with basement best build from corrugated board.

Metal profiles are widely used in construction. It has a fairly wide range of colors, and you can order the size you need.

garage door, as a rule, are placed with an offset in one direction or another. This is done so that shelving and a metal box for storing various fuels and lubricants can be placed on one of the walls of the garage. It is also possible to provide for the arrangement of the garage with mezzanines.

With the advent of such a wonderful structure as garage, and also in the basement, your life will gain even more fresh colors and moments.

Imagine how pleasant it will be to go into your own cellar in winter for a jar of goodies prepared in the summer. And most importantly, you yourself were able to build a garage with a basement. And this article has greatly helped you with this.

How to build a basement in a private house?

How to turn a basement into a living room?

Converting your basement into a living room can provide additional living space. You can use it as a gym, billiards, sauna, etc.

But there are some "pitfalls" here. We will look at all the difficulties in converting a basement into an apartment in a specific article.

The first question that comes to mind is how much it will cost per conversion. To answer accurately, you need to prepare a design and evaluate the operating data. However, you can make a rough independent estimate of the amount of work and costs involved in construction.

To answer this, you need to answer a few questions:

“Or your basement is dry enough to live in.”

If this is the case, it is relatively easy to solve other problems. When groundwater flows in the basement, mold or fungi on the walls, construction and renovation costs will increase significantly.

— What is the height of the basement? If you have a basement that is 2.5m or larger, it will fit the bill. In case you have less height, the space is suitable for billiards, sauna, gym.

— The presence of windows in the basement.

This does not necessarily mean having a window, but openings for their placement. The minimum width of the window should be at least 0.9 m. Of course, you can also widen the opening using your own hammer. But the vast majority of walls in the basement are carriers. This makes it difficult to enlarge the hole in the window.

Solutions to the problem.

- If the building is built on land with good soil permeability and the degree of occurrence of underground and groundwater, below the foundation level, at least 1 m.

Then you should not have problems with basement flooding.

What's worse is when there is water in the basement during the rainy season, humidity. It's quite difficult and expensive to make it harmless. To do this, you need to insulate the external walls of the basement, which will add additional heat to the basement.

Provide good drainage around the foundation. If these works are not carried out, the following tasks will not be possible in the following years: electrical installation and floor installation...

Typically, all basement walls are located in the basement. Therefore, redesign and radical design ideas are not suitable here.

DIY basement under the house

If the basements are not suitable for living, i.e. they do not have a height of 2.5. , you can increase it by removing the top layer in the basement. This method is usually the simplest and cheapest.

— Proper lighting in the rooms, we will increase the window openings. Do them where you like best. The easiest way to get basement windows is to place them 15-20cm above the ground.

This will solve the problem of rainwater and snow in winter.

— Sewerage in a deep basement should not be combined into a common tank. Because levels vary depending on the soil. To overcome this problem, you need to purchase pumping station. For a family who uses a toilet, washing machine, shower, washbasin, the size of a suitcase pump will be enough.

Expansion of windows in the basement.

It is easier to expand windows on high bases when the basement is above ground. The complex, already a task, will expand the windows in depth...

Basement recess.

Converting a basement into a residential building involves increasing its height to at least 2.5 m. We will tell you how to do this.

How to build a basement with your own hands

In our country, suburban housing has personal plots, which are usually used for gardens and vegetable gardens. A spacious and dry cellar in the house is necessary to preserve the harvest.

An office space for this purpose can be arranged in the basement under a residential building, garage or barn. It is also possible to build a separate structure. The final decision on the location of the cellar should be made based on the results of a study of the house and land.

Return to contents

Preliminary work before construction

The site is studied during engineering and geotechnical surveys, for which specialists from design organizations are involved. In order to save money, you can do it yourself and conduct research on the soils and hydrogeological conditions of the area yourself.

A good result is obtained by interviewing neighbors and inspecting their cellars or basements.

When studying site conditions, you should pay attention to the following points:

- soil composition, depth of soil layers, tendency to accumulate moisture and heaving;

- groundwater level and the height of its rise during snow melting or intense precipitation;

- average depth of soil freezing.

This data will be necessary in the process of choosing the most optimal type of cellar for the given conditions and the method of its construction. Specialists use the obtained data in the process of design, calculation and estimate work.

The best option for the homeowner is, without a doubt, a cellar under the house with an entrance from the interior. It is better to lay such a structure at the construction stage. The option of constructing a buried structure during the reconstruction process is also possible, but it is quite troublesome and time-consuming.

Small cellar

Small cellar

Basics of cellar design

A country house with a basement equipped for storing supplies is being built taking into account the requirements of SNiP 31-02-2001 and SNiP 2.08.01-89, as well as RSN 70-88.

IN regulatory documents the geometric dimensions of residential and office premises have been determined. When equipping cellars, special attention is paid to the issue of waterproofing the walls and floors of buried storage facilities, as well as the necessary air exchange.

The main task that is solved during the construction of this room is to ensure a relative constant temperature at 8-12 °C with low air humidity.

During the design work, it is necessary to provide a ventilation system. In the vast majority of cases, a vertical duct with an external exhaust pipe is sufficient.

This method of air exchange does not require complex equipment or any operating costs.

Cellar ventilation diagram

Cellar ventilation diagram

A cellar in a private house is designed taking into account the overall size of the building.

When making calculations, the following points should be taken into account:

- It is recommended to locate the storage facility near the geometric center of the building at an equal distance from the outer contour of the foundation.

- The depth of the cellar is selected taking into account the groundwater level and the degree of seasonal fluctuations.

- In the process of design activities, such a factor as soil composition must be taken into account.

The central placement of the cellar minimizes the impact of temperature fluctuations due to the cooling of soil masses and their freezing during the onset of cold weather. It is good if the entrance to the service premises is directly from the house - this will significantly reduce heat loss.

Drawing and diagram of the construction of the simplest cellar under the house

Drawing and diagram of the construction of the simplest cellar under the house

Cellars are classified, first of all, according to the degree of their deepening, which, in turn, depends on the level of groundwater fluctuations:

- Underground structures are built when water layers are lower than 3-3.5 m or under houses located on a hill.

- A semi-buried cellar is erected when the depth of soil water is no more than 0.8-1.2 m from the surface.

- Above-ground storage facilities are constructed in areas where there is no possibility or use of underground or semi-underground premises due to the high probability of flooding.

Read also

How to make a roof drain

The choice of a specific type of cellar should be based on objective data and the results of many years of observations.

Cellars can be made in different designs. Return to contents

Cellars can be made in different designs. Return to contents

How to make a cellar in your home with your own hands

Preparation for the construction of an underground storage facility under a residential building

At the stage of laying the foundation, it is necessary to mark the pit and dig it.

Excavation work is carried out in compliance with rules and safety measures. The total depth of the pit should be about 2.7-3 m, and the diameter should be at least 2.5 m. Round shape for a buried structure is optimal and ensures its maximum strength. On the other hand, rounding a wall requires quite high qualifications from the mason.

Another option is the construction of monolithic walls made of concrete reinforced with steel or composite rods. This technology can ensure maximum resistance of underground structures to external mechanical loads. To make a cellar in a house correctly, you should evaluate your financial capabilities and practical skills in performing construction operations.

The choice of a specific technology for the construction of an underground structure will allow an assessment of the required amount of building materials.

To build load-bearing walls we need red brick. The amount of material is calculated based on minimum thickness the walls, as they say among professional masons, are one and a half bricks long. When choosing a brick, special attention should be paid to its quality.

In this video you can see how to build cellar walls with your own hands from bricks

For underground structures, the use of bricks of heterogeneous composition, having deep cracks or inclusions is unacceptable.

Construction material must be stored in proper conditions. Long stay brick in conditions of high humidity can lead to a deterioration in its qualities and properties. When purchasing materials, you should ask the seller for certificates of conformity.

The walls of an underground storage facility must be built on a reliable foundation. Typically, the role of the base is performed by a reinforced reinforced concrete belt at the bottom of the structure. It is quite possible to build a cellar in a house with your own hands, especially if you strictly follow the construction technology.

Waterproofing floors and walls

Buried structures require high-quality protection from moisture penetration through building structures.

Most probable ways water entering the cellar or basement:

- the presence of through gaps;

- violations of technology during bricklaying;

- penetration of moisture through capillaries in an array of building materials;

- the formation of condensation on walls or other surfaces due to temperature changes or insufficient air exchange.

Typically, waterproofing of walls, floors and ceilings is done using roofing felt. It is recommended to lay this roll material in two layers. The overlap of the sheets should be at least 10-12 cm, and each subsequent row should be laid perpendicular to the previous one. Under the waterproofing it is necessary to pour a gravel-sand cushion with a thickness of at least 100-150 mm.

Scheme of the cellar waterproofing device

Scheme of the cellar waterproofing device

It is possible to correctly build a cellar under a house with high-quality waterproofing of the walls during the process of laying the foundation.

In this case, the work will not be interfered with by other structures and elements of the building. During the construction of walls, bitumen mastic is applied to their outer surface, onto which, in turn, roofing material is glued. When performing this operation, the sheets are arranged vertically with an overlap of 8-10 cm.

Pouring the floors in the cellar is carried out with mandatory reinforcement with a two-layer steel coarse mesh.

The screed is filled with a cement-sand mixture with the addition of a fine fraction of crushed stone as a filler. The mixture is prepared on site by hand or using a concrete mixer. It is possible to order concrete from a specialized enterprise with delivery to the work site by vehicle with the appropriate equipment.

Scheme of correct filling of the floor in the cellar

Scheme of correct filling of the floor in the cellar

Overlapping device

When ready load-bearing structures walls and floor, you can begin to build the ceiling above the cellar.

Taking into account the fact that the structure is of a buried type, the best material There will be a reinforced concrete slab for the floor. The calculation of the required number is carried out taking into account the length and width of the structure. When laying floor slabs, heavy construction equipment is used - a crane on a vehicle chassis.

B1 in English what level?

B1 in English what level? Managing verbs in German - German online - Start Deutsch

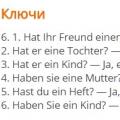

Managing verbs in German - German online - Start Deutsch Conjugation of the verb haben (to have) in the present tense

Conjugation of the verb haben (to have) in the present tense