Materials with high heat capacity. Density and specific heat capacity of brick

Brick is a popular building material in the construction of buildings and structures. Many people only distinguish between red and white brick, but its types are much more diverse. They differ both in appearance (shape, color, size) and in properties such as density and heat capacity.

Traditionally, a distinction is made between ceramic and sand-lime bricks, which have different manufacturing technologies. It is important to know that the density of brick, its specific heat capacity, and each type can differ significantly.

Ceramic brick is made from various additives and fired. Specific heat ceramic bricks equal to 700…900 J/(kg deg). Average density ceramic brick has a value of 1400 kg/m 3. The advantages of this type are: smooth surface, frost and water resistance, as well as resistance to high temperatures. The density of ceramic brick is determined by its porosity and can range from 700 to 2100 kg/m3. The higher the porosity, the lower the density of the brick.

Sand-lime brick has the following varieties: solid, hollow and porous; it has several standard sizes: single, one-and-a-half and double. Average density sand-lime brick is 1600 kg/m3. The advantages of sand-lime brick are excellent soundproofing. Even if you lay a thin layer of such material, the sound insulation properties will remain at the proper level. The specific heat capacity of sand-lime brick ranges from 750 to 850 J/(kg deg).

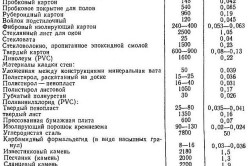

Brick density values various types and its specific (mass) heat capacity at various temperatures are presented in the table:

| Type of brick | Temperature, °C |

Density, kg/m 3 |

Heat capacity, J/(kg deg) |

|---|---|---|---|

| Trepelny | -20…20 | 700…1300 | 712 |

| Silicate | -20…20 | 1000…2200 | 754…837 |

| Adobe | -20…20 | — | 753 |

| Red | 0…100 | 1600…2070 | 840…879 |

| Yellow | -20…20 | 1817 | 728 |

| Building | 20 | 800…1500 | 800 |

| Facing | 20 | 1800 | 880 |

| Dinas | 100 | 1500…1900 | 842 |

| Dinas | 1000 | 1500…1900 | 1100 |

| Dinas | 1500 | 1500…1900 | 1243 |

| Carborundum | 20 | 1000…1300 | 700 |

| Carborundum | 100 | 1000…1300 | 841 |

| Carborundum | 1000 | 1000…1300 | 779 |

| Magnesite | 100 | 2700 | 930 |

| Magnesite | 1000 | 2700 | 1160 |

| Magnesite | 1500 | 2700 | 1239 |

| Chromite | 100 | 3050 | 712 |

| Chromite | 1000 | 3050 | 921 |

| Chamotte | 100 | 1850 | 833 |

| Chamotte | 1000 | 1850 | 1084 |

| Chamotte | 1500 | 1850 | 1251 |

It is necessary to note another popular type of brick – facing brick. He is not afraid of either moisture or cold. The specific heat capacity of such a brick is 880 J/(kg deg). Facing brick has shades from bright yellow to fiery red. This material can be used for finishing and facing work. The density of this type of brick is 1800 kg/m3.

It is worth noting a separate class of bricks - refractory bricks. This class includes dinas, carborundum, magnesite and fireclay bricks. Refractory bricks are quite heavy - the density of bricks of this class can reach 2700 kg/m3.

Carborundum brick has the lowest heat capacity at high temperatures - it is 779 J/(kg deg) at a temperature of 1000°C. Masonry made from such bricks warms up much faster than fireclay bricks, but retains heat less well.

Refractory bricks are used in the construction of furnaces with operating temperatures up to 1500°C. The specific heat capacity of refractory bricks depends significantly on temperature. For example, the specific heat capacity of fireclay bricks is 833 J/(kg deg) at 100°C and 1251 J/(kg deg) at 1500°C.

Sources:

- Franchuk A.U. Tables of thermal technical indicators building materials, M.: Research Institute of Construction Physics, 1969 - 142 p.

- Tables of physical quantities. Directory. Ed. acad. I.K. Kikoina. M.: Atomizdat, 1976. - 1008 p. construction physics, 1969 - 142 p.

- Industrial ovens. Reference manual for calculations and design. 2nd edition, expanded and revised, Kazantsev E.I. M., “Metallurgy”, 1975. - 368 p.

- Use of various materials in construction

- Tree

- Brick

Creating an optimal microclimate and the consumption of thermal energy for heating a private house in the cold season largely depends on thermal insulation properties building materials from which the building is constructed. One of these characteristics is heat capacity. This value must be taken into account when choosing building materials for constructing a private house. Therefore, the heat capacity of some building materials will be considered next.

Definition and formula of heat capacity

Each substance, to one degree or another, is capable of absorbing, storing and retaining thermal energy. To describe this process, the concept of heat capacity was introduced, which is the property of a material to absorb thermal energy when heating the surrounding air.

To heat any material with mass m from temperature t start to temperature t end, you will need to spend a certain amount of thermal energy Q, which will be proportional to the mass and temperature difference ΔT (t end -t start). Therefore, the heat capacity formula will look like this: Q = c*m*ΔТ, where c is the heat capacity coefficient (specific value). It can be calculated using the formula: c = Q/(m* ΔT) (kcal/(kg* °C)).

Conventionally assuming that the mass of the substance is 1 kg, and ΔТ = 1°C, we can obtain that c = Q (kcal). This means that the specific heat capacity is equal to the amount of thermal energy that is expended to heat a material weighing 1 kg by 1°C.

Return to contents

Using heat capacity in practice

Building materials with high heat capacity are used for the construction of heat-resistant structures. This is very important for private houses in which people live permanently. The fact is that such structures allow you to store (accumulate) heat, thanks to which the house maintains a comfortable temperature for quite a long time. First, the heating device heats the air and the walls, after which the walls themselves warm the air. This allows you to save cash on heating and make your stay more comfortable. For a house in which people live periodically (for example, on weekends), the high thermal capacity of the building material will have the opposite effect: such a building will be quite difficult to heat quickly.

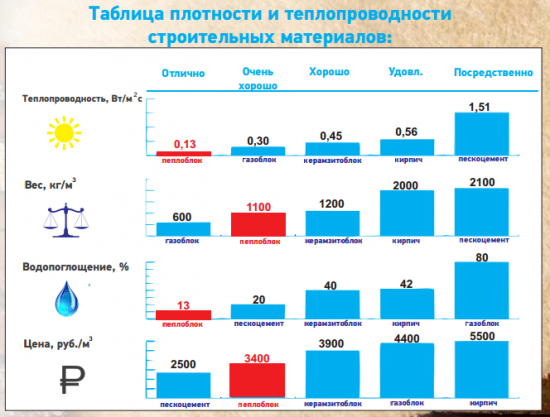

The heat capacity values of building materials are given in SNiP II-3-79. Below is a table of the main building materials and their specific heat capacity values.

Table 1

Brick has a high heat capacity, so it is ideal for building houses and constructing stoves.

Speaking about heat capacity, it should be noted that heating stoves It is recommended to build from brick, since its heat capacity is quite high. This allows you to use the stove as a kind of heat accumulator. Heat accumulators in heating systems (especially in water heating systems) are used more and more every year. Such devices are convenient because they only need to be heated well once with the intense fire of a solid fuel boiler, after which they will heat your home for a whole day or even more. This will significantly save your budget.

Return to contents

Heat capacity of building materials

What should the walls of a private house be like in order to comply with building codes? The answer to this question has several nuances. To understand them, an example will be given of the heat capacity of the 2 most popular building materials: concrete and wood. has a value of 0.84 kJ/(kg*°C), and wood – 2.3 kJ/(kg*°C).

At first glance, you might think that wood is a more heat-intensive material than concrete. This is true, because wood contains almost 3 times more thermal energy than concrete. To heat 1 kg of wood you need to spend 2.3 kJ of thermal energy, but when cooling it will also release 2.3 kJ into space. At the same time, 1 kg of concrete structure can accumulate and, accordingly, release only 0.84 kJ.

But don't rush to conclusions. For example, you need to find out what heat capacity 1 m2 of concrete and wooden wall 30 cm thick. To do this, you first need to calculate the weight of such structures. 1 m2 of this concrete wall will weigh: 2300 kg/m3 * 0.3 m3 = 690 kg. 1 m 2 of wooden wall will weigh: 500 kg/m 3 * 0.3 m 3 = 150 kg.

- for a concrete wall: 0.84*690*22 = 12751 kJ;

- For wooden structure: 2.3*150*22 = 7590 kJ.

From the obtained result we can conclude that 1 m 3 of wood will accumulate heat almost 2 times less than concrete. An intermediate material in terms of heat capacity between concrete and wood is brickwork, a unit volume of which under the same conditions will contain 9199 kJ of thermal energy. At the same time, aerated concrete, as a building material, will contain only 3326 kJ, which will be significantly less than wood. However, in practice, the thickness of a wooden structure can be 15-20 cm, when aerated concrete can be laid in several rows, significantly increasing the specific heat capacity of the wall.

In construction, a very important characteristic is the heat capacity of building materials. The thermal insulation characteristics of the walls of the building depend on it, and, accordingly, the possibility of a comfortable stay inside the building. Before you begin to familiarize yourself with the thermal insulation characteristics of individual building materials, you need to understand what heat capacity is and how it is determined.

Specific heat capacity of materials

Heat capacity is a physical quantity that describes the ability of a material to accumulate temperature from a heated environment. Quantitatively, specific heat capacity is equal to the amount of energy, measured in J, required to heat a body weighing 1 kg by 1 degree.

Below is a table of the specific heat capacity of the most common materials in construction.

- type and volume of heated material (V);

- the specific heat capacity of this material (Sud);

- specific gravity (msp);

- initial and final temperatures of the material.

Heat capacity of building materials

The heat capacity of materials, the table for which is given above, depends on the density and thermal conductivity of the material.

And the thermal conductivity coefficient, in turn, depends on the size and closedness of the pores. A fine-porous material, which has a closed pore system, has greater thermal insulation and, accordingly, lower thermal conductivity than a large-porous one.

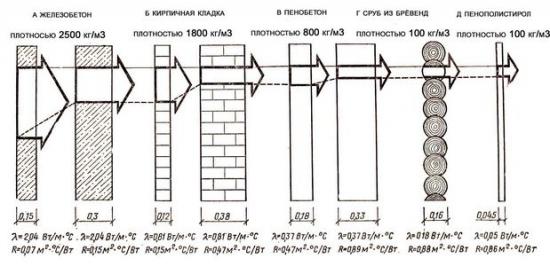

This is very easy to see using the most common materials in construction as an example. The figure below shows how the thermal conductivity coefficient and the thickness of the material influence the thermal insulation qualities of external fences.

The figure shows that building materials with lower density have a lower thermal conductivity coefficient.

However, this is not always the case. For example, there are fibrous types of thermal insulation for which the opposite pattern applies: the lower the density of the material, the higher the thermal conductivity coefficient will be.

Therefore, you cannot rely solely on the indicator of the relative density of the material, but it is worth taking into account its other characteristics.

Comparative characteristics of the heat capacity of basic building materials

In order to compare the heat capacity of the most popular building materials, such as wood, brick and concrete, it is necessary to calculate the heat capacity for each of them.

First of all, you need to decide on the specific gravity of wood, brick and concrete. It is known that 1 m3 of wood weighs 500 kg, brick - 1700 kg, and concrete - 2300 kg. If we take a wall whose thickness is 35 cm, then through simple calculations we find that the specific gravity of 1 square meter of wood will be 175 kg, brick - 595 kg, and concrete - 805 kg.

Next, we will select the temperature value at which thermal energy will accumulate in the walls. For example, this will happen on a hot summer day with an air temperature of 270C. For the selected conditions, we calculate the heat capacity of the selected materials:

- Wall made of wood: C=SudhmuddhΔT; Sder=2.3x175x27=10867.5 (kJ);

- Concrete wall: C=SudhmuddhΔT; Cbet = 0.84x805x27 = 18257.4 (kJ);

- Brick wall: C=SudhmuddhΔT; Skirp = 0.88x595x27 = 14137.2 (kJ).

From the calculations made, it is clear that with the same wall thickness, concrete has the highest heat capacity, and wood has the least. What does this mean? This suggests that on a hot summer day, the maximum amount of heat will accumulate in a house made of concrete, and the least amount of heat will accumulate in a house made of concrete.

This explains the fact that in wooden house In hot weather it is cool, and in cold weather it is warm. Brick and concrete easily accumulate a fairly large amount of heat from the environment, but just as easily part with it.

Heat capacity and thermal conductivity of materials

Thermal conductivity is a physical quantity of materials that describes the ability of temperature to penetrate from one wall surface to another.

To create comfortable indoor conditions, it is necessary that the walls have a high heat capacity and a low thermal conductivity coefficient. In this case, the walls of the house will be able to accumulate thermal energy from the environment, but at the same time prevent the penetration of thermal radiation into the room.

The ability of a material to retain heat is assessed by its specific heat capacity, i.e. the amount of heat (in kJ) required to raise the temperature of one kilogram of material by one degree. For example, water has a specific heat capacity of 4.19 kJ/(kg*K). This means, for example, that to raise the temperature of 1 kg of water by 1°K, 4.19 kJ is required.

| Material | Raft- density, kg/m 3 |

Warm- capacity, kJ/(kg*K) |

Coefficient heat- the wire- ity, W/(m*K) |

Mass TAM for heat accumuli- transfer of 1 GJ of heat at Δ= 20 K, kg |

Relatively strong- mass of TAM relative to ratio to the mass of water, kg/kg |

TAM volume for heat accumuli- transfer of 1 GJ of heat at Δ= 20 K, m 3 |

Relatively strong- volume of TAM relative to ratio to the volume of water, m 3 / m 3 |

|---|---|---|---|---|---|---|---|

| Granite, pebbles | 1600 | 0,84 | 0,45 | 59500 | 5 | 49,6 | 4,2 |

| Water | 1000 | 4,2 | 0,6 | 11900 | 1 | 11,9 | 1 |

| Glauber's salt (sodium sulfate decahydrate) | 14600 1300 |

1,92 3,26 |

1,85 1,714 |

3300 | 0,28 | 2,26 | 0,19 |

| Paraffin | 786 | 2,89 | 0,498 | 3750 | 0,32 | 4,77 | 0,4 |

For water heating installations and liquid heating systems, it is best to use water as a heat-storing material, and for air solar systems - pebbles, gravel, etc. It should be borne in mind that a pebble heat accumulator with the same energy intensity compared to a water heat accumulator has 3 times the volume and occupies 1.6 times the area. For example, a water heat accumulator with a diameter of 1.5 m and a height of 1.4 m has a volume of 4.3 m 3, while a pebble heat accumulator in the shape of a cube with a side of 2.4 m has a volume of 13.8 m 3.

The heat storage density largely depends on the storage method and the type of heat storage material. It can be accumulated in chemically bound form in fuel. In this case, the accumulation density corresponds to the heat of combustion, kW*h/kg:

- oil - 11.3;

- coal (standard fuel) - 8.1;

- hydrogen - 33.6;

- wood - 4.2.

With thermochemical accumulation of heat in zeolite (adsorption - desorption processes), 286 Wh/kg of heat can be accumulated at a temperature difference of 55°C. The density of heat accumulation in solid materials (rock, pebbles, granite, concrete, brick) at a temperature difference of 60°C is 1417 W*h/kg, and in water - 70 W*h/kg. During phase transitions of a substance (melting - solidification), the accumulation density is much higher, Wh/kg:

- ice (melting) - 93;

- paraffin - 47;

- hydrates of salts of inorganic acids - 40130.

Unfortunately, the best building material listed in Table 2, concrete, whose specific heat capacity is 1.1 kJ/(kg*K), retains only ¼ of the amount of heat that water of the same weight stores. However, the density of concrete (kg/m3) significantly exceeds the density of water. The second column of Table 2 shows the densities of these materials. By multiplying the specific heat capacity by the density of the material, we obtain the heat capacity per cubic meter. These values are given in the third column of Table 2. It should be noted that water, despite the fact that water, despite the fact that it has the lowest density of all the materials given, has a heat capacity 1 m 3 higher (2328.8 kJ/m 3) than other materials in the table, due to its significantly higher specific heat capacity. The low specific heat capacity of concrete is largely compensated by its large mass, due to which it retains a significant amount of heat (1415.9 kJ/m 3).

It is generally accepted that any sand is suitable for construction work. But that's not true. Firstly, it is necessary to use only special construction types. Secondly, it is necessary to take into account their individual characteristics.

The specific gravity and heat capacity of this material play an important role when choosing one of its types, and they will be discussed in this article.

Its specific characteristics depend on the type of material. There are several varieties of it. By origin it is divided into natural and artificial. The first type, depending on the place of extraction, has the following varieties:

Career

Quarry sand is extracted as a result of the destruction of rocks. Its grains can be from 0.16 to 3.2 mm. Due to the nature of the extraction, it turns out to be of low quality, as it contains many impurities in the form of clay and dust.

Crushed

It is obtained through the destruction and grinding of rocks. This process takes place using special equipment, so the extraction of this sand is reflected in its high cost. Due to the resulting irregular shape, the sand grains bind well to each other and to others construction materials. When adding such material, concrete consumption is reduced.

Application: It is used for concrete structures, when pouring roads and paths, and also as a filler for dry mixtures.

The above varieties of sand differ in color. Thus, the quarry variety has a yellow and brown tint, while the river variety is found in cream and gray colors.

Artificial

It is considered as such because it undergoes special processing, after which a material is obtained that differs in properties from its original. Created by crushing natural stones.

Quartz

Is the most sought after of all artificial species. It is obtained by grinding white quartz. After a certain processing, a homogeneous composition without impurities is produced. This feature makes it possible to calculate the exact dimensions of the future structure.

Application: quartz type is widely used in finishing and decorative works, sometimes it is added when creating cement mortar, but this happens extremely rarely. It is commonly found in paints, putties and drainage filters.

There is also molding sand, it is used during molding in metal models.

Determination of quantity

This value is equal to the mass contained in a unit volume. In other words, density. Most often in reference literature it is measured in g/cm3 or kg/m3.

The specific gravity of sand depends on the amount of impurities it contains and the moisture content of the material. High water content increases the specific gravity per unit volume. Also, this indicator will depend on the location of sand storage, which can be:

- natural occurrence;

- arrangement of material in bulk;

- artificial compaction.

The same type of sand under these conditions will have different values.

According to GOST 8736-77 it is indicated that the specific gravity of construction sand can vary from 1150 to 1700 kg/m 3.

As an example, the table shows several meanings of its individual varieties.

| Type of sand | Specific gravity in kg/1 m 3 |

| River alluvial sealing | 1200-1700 |

| 1650 | |

| 1590 | |

| Career | 1500 |

| Nautical | 1620 |

| Quartz | 1600-1700 |

| Wet | 1920 |

Heat capacity

This is the ability of a material to accept, accumulate and retain energy. Heat capacity is an indicator of the thermophysical properties of sand. The ability to heat up depends on chemical composition, structure and amount of material used. That's why general indicator will depend on its dryness. Important for cement compositions and when concreting walls.

| Variety of sand | Specific heat capacity in kJ/kg per 1 0 |

| Wet quartz | 2,09 |

| River dry | 0,8 |

| Career | 0,84 |

| Nautical | 0,88 |

Construction sand is a universal material, without which no construction can be completed. This is an environmentally friendly component of solutions and mixtures. Resistant to burning and not subject to rotting. When choosing a type with high thermal conductivity, the concrete structure with it will accumulate heat and an optimal microclimate will be created in the room. This condition can persist for quite a long time. Using sand with a high index specific gravity will help save on cement.

The extermination of Soviet prisoners of war by the Nazis in the Gross Infirmary of Slavuta in the Kamenets-Podolsk region

The extermination of Soviet prisoners of war by the Nazis in the Gross Infirmary of Slavuta in the Kamenets-Podolsk region Dnieper airborne operation

Dnieper airborne operation History of war loans and assistance to the front Work with redoubled energy

History of war loans and assistance to the front Work with redoubled energy