House made of timber, interior finishing. The procedure for insulating a timber house from the inside: a description of the process

Designing a house from beams in mandatory provides insulation from the outside or inside. The microclimate of the building, the level of humidity, which is vital for human well-being, depends on this.

Compared to houses made of stone, silicate blocks, and bricks, the insulation of a timber house from the inside has its own specific characteristics.

Preliminary work

To carry out the work you will need:

- special tool;

- vapor barrier film;

- thermal insulation materials;

- instructions for carrying out work;

- preliminary preparation.

Need to be eliminated:

- cracks;

- gaps;

- chips.

It is strongly recommended to pay special attention to the condition of the walls and evaluate the quality of the insulation work already carried out, if any. The choice of material and further actions depend on the quality of processing of joints, joints of beams, corners.

The most common defects:

- lack of insulating material;

- thinning of the caulk layer.

Attention! All work on wall insulation will be nullified in the absence of insulation of the foundation, which it is advisable to do at the excavation stage. If the foundation is not insulated, it will need to be excavated and insulated.

Features of preparatory work

The most common materials used to correct chips, cracks and other defects are:

- flax tow or jute fiber;

- polymer compositions;

- polyurethane foam.

You should not neglect this stage, relying on the properties of the advanced finishing materials used and the quality of the beams. Compliance with construction technology is the basis for a successful result.

The most common mistake that accompanies the insulation of the walls of a log house from the inside is an attempt to speed up the process. Even the most expensive material is not able to retain heat in a room if all sorts of defects that arose during the shrinkage process are not repaired.

To eliminate cracks, you need to carry out the following work:

- thicken;

- caulk.

One of the most popular and affordable materials used for sealing cracks is jute fiber. If you do the work yourself, you will need a special chisel; use it to easily fill the recesses.

For large cracks, the ideal option is tape tow, which must be rolled into a roller.

Wood processing

Insulation of a log house inside requires compliance with mandatory sanitary and hygienic requirements, which help prevent the spread of fungi and mold. There are more than enough antiseptics on sale at various prices, which are recommended to be purchased in accordance with the specific climate conditions.

Stages of insulation

Selection of materials

Requirements for materials used for insulation:

- ease of use;

- environmental friendliness;

- safety for humans and environment;

- fire safety;

- durability.

To carry out the work, it is necessary to purchase exclusively safe materials, preventing negative effects on humans. For this purpose, you should carefully study the factory instructions, which contain comprehensive information, including regarding installation.

There are special thermal insulation materials that are coated with a film during the production process; their prices differ accordingly, but the advantage is obvious: reducing the duration of installation work and no costs for vapor barrier.

Attention! The insulation of a bathhouse made of timber from the inside is carried out according to the same rules as the insulation of a house. Only materials need to be selected whose condition is not affected by high temperature.

Vapor barrier of walls

If thermal insulation without film is used, after preparatory work You can safely start vapor barrier. The main purpose of this stage is to prevent moisture condensation on the surface of the walls due to sudden changes in temperature conditions.

The traditional method of vapor barrier, which provides the desired effect and has a low price, is a vapor barrier film.

High-quality vapor barrier prevents the settling of excess moisture. The spread of fungus and mold is excluded. Carrying out this type of work will ensure a long service life of the building and a normal microclimate in the room.

Insulation of floors

In addition to the walls, insulating a house made of 150x150 timber from the inside involves carrying out appropriate work on the floor. This type of work has been considered mandatory since the appearance of the first houses made of timber. An insulated floor reduces overall heat loss by 20%, which is a very high figure in construction.

The simplest and most affordable option is to insulate the floor with mineral wool. If for some reason the floor is already covered, do not hesitate to dismantle it, otherwise retaining heat will be very problematic. First of all, the subfloor is laid out, a waterproofing film and insulation are laid on it. Expanded polystyrene is popular.

This requires preliminary preparation:

- it is necessary to backfill and level the gravel bed, approximately 40 cm;

- the layer is thoroughly compacted;

- sand is poured on top - 10 cm;

- reinforced concrete is poured, which takes about two weeks to dry completely;

- Polyethylene film is laid on the finished base and only after that polystyrene is laid.

Insulation of ceilings

Providing thermal insulation for the ceiling is an equally important step, especially in areas with northern climatic conditions.

The most common materials that do not require special training to work with are:

- polyplex or foam;

- polyethylene foam;

- mineral wool;

- expanded clay

In addition to special modern materials, many people prefer the classic option - sawdust.

The advantages of this material are obvious:

- accessibility;

- environmental friendliness;

- ease of use.

To ensure a long service life of sawdust, you should definitely use a special antifungal agent; it is also useful to use a fire retardant to increase fire resistance.

Conclusion

We hope that we were able to cover in sufficient detail the process of insulating wooden houses (see also article). In the video presented in this article you will find additional information on this topic.

Any wooden house is distinguished by its environmental friendliness and excellent microclimate. But problems sometimes arise with the level of thermal insulation in buildings made of logs or timber. It is worth considering the issues of insulating a timber home from the inside.

There are many aspects that determine how pleasant your stay will be. Internal insulation must be carried out taking into account certain requirements and using suitable materials. We read about insulating a house made of timber from the outside here.

Is it necessary to insulate a timber house from the inside?

The cold inside a log house appears mainly due to the presence of poorly insulated areas. Often, the presence of gaps in the thermal insulation of a building leads to drafts. Owners may feel discomfort due to the presence of gaps between the beams, due to improper placement of the insulation, and also as a result of drying out of the wood. The result of all this is a decrease in the thermal insulation capabilities of the building as a whole.

Internal insulation of timber dwellings is not carried out as often as external insulation. The reasons for this include the loss of a certain usable area of the house and the risk of increased humidity in the premises. But sometimes owners cannot perform external thermal insulation. Then they should turn to the method that will be discussed further. All processes assumed in this case are carried out in a certain order.

Sequence of work:

1. Elimination of cracks in the walls and preparation of the working surface.

2. Arrangement of a vapor barrier layer.

3. Installation of the frame under the facing coating.

4. Laying thermal insulation materials and sealing gaps.

5. Creation of finishing cladding taking into account ventilation requirements.

The owner of a house made of timber must understand that thermal insulation must be approached comprehensively. In addition to insulating the walls, it is also necessary to pay attention to eliminating the gaps between the window blocks and the opening. Sometimes additional thermal insulation of slopes and window sills is required. If you solve all these problems correctly and with the help of suitable insulation, an excellent microclimate will be established in a house made of timber.

Stages of insulating a timber house from the inside

It is necessary to carry out work on thermal insulation of a timber dwelling in order. The main stages were presented earlier. Now it’s worth spending more time considering each of them.

1. Preparation and caulking of walls

First of all, you should assess the condition of the walls. Checking the quality of caulking is quite simple. To do this, you need to look to see if there are any gaps between the individual beams and at the corners of the building. If damage is detected, it is necessary to remove contaminants and clean off dust. Next, the timber is coated with an antiseptic composition. The next task is to caulk the cracks.

A house made of timber must be caulked a year after it is erected. Wood shrinkage in any case leads to the formation of cracks. Defects are sealed with tow or jute. They are placed in the gaps until they completely rest against the obstacle.

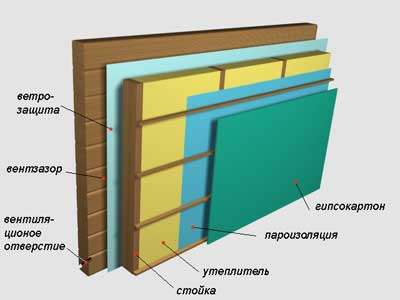

2. Installation of a vapor barrier

When internally insulating a timber structure, the thermal insulation is located between the materials that provide a vapor barrier. But then there will be a need to provide additional ventilation so that the walls do not rot. To create a vapor barrier, a vapor barrier film is used. It should be placed with the smooth side facing wooden wall. Then the thermal insulation material will be well protected from damage, since the timber releases a certain amount of moisture. As a result of getting wet, the insulation may rot. This especially applies to mineral wool.

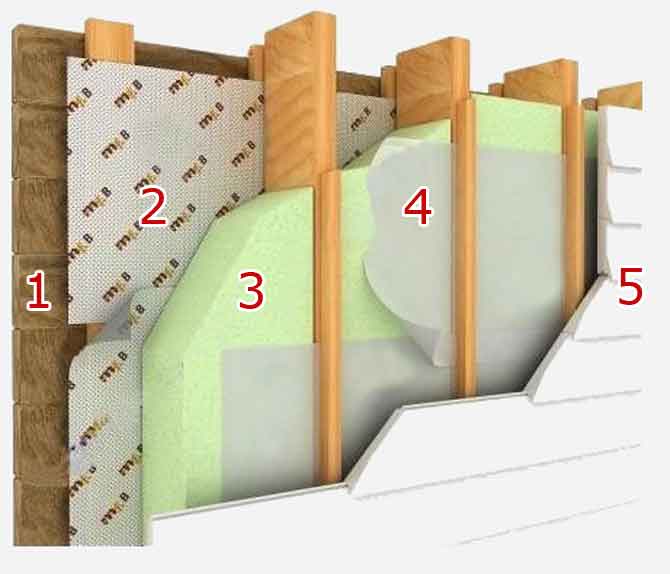

3. Installation of timber lathing on the walls

To create the lathing, materials of different types are used. A timber or metal profile is suitable for this. But in any case, corner posts are installed so that later the cladding can be installed as evenly as possible. The racks are placed strictly vertically, which is checked by level. These elements must be installed at a distance that is 1.5 cm less than the width of the heat-insulating material used. If bars are used for sheathing, they must be coated with antiseptic substances and fire retardants.

4. Selection and installation of insulation into the structure

To determine the best option for a heat insulator, you should first calculate your financial capabilities. It will be cheaper to use expanded polystyrene or penoplex. But internal thermal insulation using such insulation may be unsafe. Therefore, it is much better if the owner chooses environmentally friendly materials. This could be, for example, ecowool or mineral wool.

Mineral wool sheets are laid between the sheathing elements. To cut the required piece from a roll, you must first determine the height of the walls. You also need to remember that the width of the sheets should be 1.5 cm greater than the distance between the sheathing posts. Otherwise, it will not be possible to lay the mineral wool slabs tightly.

If the owner uses modern materials for thermal insulation, additional fastening may not be required. After laying it, a vapor barrier film is spread over the thermal insulation layer. You can attach it using a stapler. It is important to ensure that the vapor barrier strips have an overlap of 15 cm. The joints between the sheets of material are glued together with tape. It is necessary to ensure that the vapor barrier is laid with the rough side facing the living space, and not vice versa.

5. Ventilation and wall finishing with plasterboard

Since the placement of mineral or ecowool leads to increased air humidity in the room, it is necessary to ensure good ventilation. To do this, plasterboard panels or lining are fixed to the sheathing in such a way that they move away from the vapor barrier layer by 2-3 cm. This can be done if, after laying the mineral wool, additional bars with a cross-section of 30×40 mm are installed. They become the basis for further installation of false walls. To create even better ventilation in the room, it is advisable to make an intensive exhaust hood with a blower fan. Then the humidity will not increase, and the risk of fungus will disappear.

Proper implementation of internal thermal insulation in a house made of timber will save owners from many problems. Therefore, they need to approach the implementation of such an event as carefully as possible.

If you are going to build a wooden house, then the relevant question is how to insulate it from the inside. This point must be taken into account at the design stage.

Any wooden building requires mandatory insulation both outside and inside.

The work is being carried out in stages. The process should include:

- preparation of the working surface;

- leveling and sealing cracks;

- production of a vapor barrier;

- installation of sheathing (it is installed on load-bearing walls);

- laying the heat insulator and sealing it;

- manufacturing ventilation system;

- performing interior decoration of the premises.

Thermal insulation of walls

To fill the cracks you will need jute fiber.

To complete the first stage, you need to use special compounds with antifungal and antiseptic effects. The treatment must be carried out very carefully, only in this case the walls will be maximally protected from negative impact environment.

You will need jute fiber to fill the gaps. Fill all the cavities inside the walls with it using a special chisel. If there are large cracks in the surface of the walls, then they need to be filled with tape tow, which is rolled up before being placed in the cavity.

To prevent the accumulation of moisture that enters from the inside, it is necessary to create a vapor barrier in the thickness of the wood. To do this, the entire surface of the walls that will be insulated is covered with a special film.

Next is the sheathing load-bearing walls. This is also a multi-step process. First of all, vertical racks are made from timber, which are installed in the corners, with a cross-section of 5x10 cm and the same length as the height of the room. Along the edge of this beam there is a beam of the same length, but with a cross-section of 5x5 cm. The beams are fastened together with self-tapping screws. The result should be a stand in the shape of the letter “L”. Such racks are installed in all corners. They must be positioned strictly vertically; a level is used for this. When the racks are installed, vertical bars with a section of 5x5 cm must be mounted between them at a distance of about 60 cm.

Insulation is laid on the mounted sheathing. Most often, mineral wool is used for this purpose. It needs to be cut into strips, the width of which will be 1-2 cm greater than the distance between the vertical bars. Fix the insulation with anchors to the wall. It is necessary to fill all the empty space between the sheathing beams with insulation. After this, another layer of waterproofing film is stretched over the insulation.

After the second layer of the vapor barrier membrane is stretched, you can complete the interior decoration of the house from timber. Sheathing the inside of the house is done after the film is secured to the sheathing beams. You can use a construction stapler for this. 3x4 cm bars are mounted on top of the staples used for fixation.

The interior cladding of the house is made of wooden paneling. This will allow for additional wall insulation. At the same time, the interior will be designed in the characteristic style of a house made of timber. Can be used instead of lining and plank. Externally, this material resembles a small beam. Its installation is best done horizontally.

High-quality insulation of a house made of timber is impossible without creating an effective ventilation system.

This will allow you to maintain comfortable humidity in the room. A forced-type ventilation system is necessary because insulating the walls will increase the humidity in the room. The ideal version of such a system is a network of hidden channels that will be discharged into the attic. Forced air circulation can be provided by a low-power fan. It will be enough to turn it on for 25-30 minutes a day to create conditions that are comfortable for staying in the house.

How to insulate a wooden house from the inside?

Log houses have been gaining momentum lately. They are chosen not only for their low cost and environmental friendliness, but also because they can be erected in a short time and at any convenient time (both in winter and summer).

However, such buildings require additional thermal insulation, especially in our country, where the climate in winter is very harsh in some places.

Many, faced with such a problem, wondered whether it is possible to insulate a house made of timber from the inside and how to do it correctly?

Before answering this question, it is necessary to understand the reasons for the penetration of cold air into the room. There may be several of them:

- Incorrect installation and selection of insulation thickness contribute to the penetration of cold air into the room.

- Between the beams there are holes and cracks that formed during shrinkage or improper installation.

Stages of insulating a house made of timber inside

Internal insulation of a timber house includes several stages:

- Preparing the premises.

- Leveling out all irregularities and holes.

- Vapor barrier.

- Frame.

- Insulating a timber house from the inside using materials.

- Ventilation.

- Decorating the rooms from the inside.

Preparing the room for insulation

Before you start insulating a timber house inside, you need to do a number of preparatory work:

- cleaning all surfaces from dust and dirt (wallpaper, if any, should be removed);

- treat the surface with a special antiseptic solution (this must be done to prevent insects and mold from appearing);

- it is necessary to treat the surface with a solution that protects the wood from burning;

- All wiring that runs along the wall should be separated from the surface.

Wall treatment

![]()

Sealing cracks

At this stage, it is necessary to close all existing cracks, even the smallest ones, using jute fiber. The void is filled using a chisel. For large holes, use tape tow.

Note: If the house has just been built and no one lives in it, then it is necessary to close all the holes again in a year. If people live in the building, then this procedure can be carried out after a couple of years, since shrinkage occurs more slowly than in a non-residential building.

Vapor barrier

The accumulation of moisture between the timber can lead to rotting of the wood. To avoid this, they create a barrier - a vapor barrier and waterproofing film, which is placed on the beam with the rough side. This must be done before you begin to insulate the inside of the wall.

Thanks to the correctly positioned vapor barrier/waterproofing film, moisture does not reach the wood.

Frame/Lathing

The racks are made in advance so that the corners are of the desired shape. The length of the beam will be equal to the height of the room (section 5 × 10 cm).

Cut another strip with the same length, but with a different cross-section (5x5 cm). It is attached using self-tapping screws to the edge of the beam. The result is a design that resembles the letter “G”.

It is worth noting that there should be exactly as many such racks as there are corners in the room. To ensure that the racks are in the desired position, use a level. Then, keeping a distance of half a meter between the slats, install bars with a cross section of 5x5 cm vertically.

Laying insulation

Installation of insulation material

Used for thermal insulation mineral wool. It is worth noting that the width of the insulation should be a couple of centimeters larger than the gap between the bars.

Using anchors, during installation, the insulation is fixed to the wall.

Advice: For additional thermal insulation (that is, to improve it), another layer of film is placed.

Finishing work

A stapler is used to attach polyethylene to the block. As soon as the film is fixed, they move on to finishing the room.

Ventilation system

After thermal insulation, the air humidity in the house will increase, so you should create a ventilation system: with its help, the microclimate will improve.

An attic is perfect for this purpose, where you can place the entire ventilation system. To start air circulating, you can use a fan with a low power level.

In winter, you need to turn on the fan for half an hour every day.

Insulation of the floor in a house made of timber from the inside

To reduce heat loss in wooden house, it is necessary to insulate the floors. To do this, use mineral wool/foam. If the floor is already covered, it must be dismantled.

Important detail: After dismantling the floor, a rough covering is made from the base of the structure, on which polyethylene is placed. The gaps between the joists are sealed with insulating material.

If you are going to insulate using polystyrene foam, you must first pour gravel into the floor structure to a depth of forty centimeters, and then level it.

It will take about two weeks for the concrete to dry completely. After two weeks, a film is laid on the rough coating, and then foam plastic.

Ceilings

To insulate the ceiling, foam plastic/mineral wool/expanded clay is used.

However, despite the wide choice of thermal insulation material, most owners use sawdust. This type of insulation is good because it is highly environmentally friendly and low cost.

But before insulating the ceiling with it, it must be treated with an antiseptic solution. This can prevent the appearance of fungus. This material is also treated with antipyrine so that in the event of a fire, it will not catch fire.

To avoid the appearance of rodents, the sawdust should be thoroughly dried and lime should be added to it. This insulation is tightly placed in voids.

What should you consider when choosing insulation?

Range of insulation materials

To choose insulation that is as safe as possible for health, you need to pay attention to the combination of material and wood. The insulation must not only be well ventilated, but it must also be in harmony with the properties and vapor permeability of the wood.

Attention: Many people prefer foam. But it is worth noting that such material does not allow moisture to pass through well, so it should not be used for internal or external thermal insulation of a room (condensation will drip onto the wood, which will lead to rotting of the timber).

Despite the fact that basalt and fiberglass are non-natural materials, they have excellent vapor-permeable properties. If there is a ventilation system, moisture will not accumulate.

But it is worth noting that such materials emit harmful substances, which enter the room during ventilation. As a result, a person breathes them. Of course, if you install the film, then no harmful particles will enter the room, but the beneficial microclimate of the tree will also disappear.

As for flax fiber and fiberboard, they are best combined with the properties of wood.

Video about internal insulation of a timber house

Accounting accounts 60.01. Expanded balance. Accounting for advances issued

Accounting accounts 60.01. Expanded balance. Accounting for advances issued How to process payment to a supplier for purchased goods and additional services provided?

How to process payment to a supplier for purchased goods and additional services provided? How to fill out a tax return?

How to fill out a tax return?