Laying laminate flooring on a wooden floor will make the old base shine with new colors. Laying laminate flooring on a wooden floor: installation technologies Lay the laminate flooring on the wooden floor with your hands

Laminate flooring can be laid on any flat, durable (stable) and dry surface. Wooden covering, concrete or other – it doesn’t really matter. There are some nuances that should be taken into account.

It is quite possible to lay laminate flooring on a wooden floor with your own hands. Many construction companies They will assure you that you first need to dismantle the old wooden floor and completely replace it. This step must be taken if the load-bearing joists have rotted. In the center of Moscow there are still buildings where wooden floors have not been changed since the 19th century, and when conducting a survey, the need for their complete replacement becomes obvious. However, this operation will cost the owner much more than a new floor covering.

Important! When diagnosing a wooden floor, you should pay attention not only to the safety of the joists and the condition of the floor boards, but also to their stable position - the boards should not “walk.” During operation, unstable elements of an old wooden floor will lead to displacement of the laminate panels relative to each other, increased wear of the locking joints and the appearance of cracks in the floor covering.

Diagnosis and leveling of wooden floors

In most cases, to diagnose the old floor, it is not necessary to open it. Such measures should be resorted to if a section of the floor has noticeably “sagged” and cannot be leveled with a layer of plywood. Or when there are serious concerns that the load-bearing joists have rotted. In other cases, the floor is visually inspected, tapped in search of possible cracks and places that creak when walking, and its horizontalness is checked. It is allowed to lay the laminate if there are differences in the plane within 2 mm per 2 m. To do this, apply a 2-meter level to the floor and look at the size of the differences in height.

Damaged boards of the old floor must be replaced. If the damage is superficial and minor, the board is removed, turned over and secured upward with the side that was previously bottom. Poorly secured boards are fixed using self-tapping screws. Subsequent leveling of the surface of the old wooden flooring only makes sense if the floor boards are well secured.

Advice . If you plan to sharpen the floor with an electric planer, use nails to fix the boards, the heads of which must be recessed into the board by 2 mm.

Old, uneven floors with significant differences in height can be leveled using an electric planer or sanding machine. Before leveling the floor with an electric planer, it is also necessary to eliminate squeaks. To do this, the boards are attached to the joists with long self-tapping screws. Self-tapping screws can be screwed into or near the holes of nails that were removed during inspection and repair. After leveling the floor, all debris is carefully removed with an electric planer, the floor boards are impregnated with an antiseptic, after which you can begin laying the laminate.

If there are a significant number of differences, which are quite difficult to remove using an electric planer, leveling the old wooden floor is done with sheets of plywood with a thickness of 10 mm or more. This can be done as long as the floor slope is satisfactory. They fasten sheets of plywood through the boards to the load-bearing joists with long self-tapping screws in order to firmly fix all the layers of the resulting “pie.” Sheets of plywood are laid staggered.

If there is a significant slope of the old wooden floor and large differences in height, the old floor is leveled using additional guides before laying the plywood. They are made from bars of different thicknesses. The plywood should first be laid out on the floor and the joints of the sheets should be marked. Laying guides from bars under the joints is mandatory. The laying step should be 500-600 mm. The bars are secured with self-tapping screws. Sound and heat insulation is laid in the gaps between the laid bars. Sheets of plywood are laid on the new guides and secured with self-tapping screws, without recessing their heads too much into the plywood. There must be a gap of 3-5 mm between the walls in the room and the sheets of plywood.

Very important! Leveling the old floor with the help of additional guides from the bars will inevitably change its level in relation to the floor in other rooms. The door may need to be replaced or rehung.

The ventilation hole that was in the old wooden floor, must be saved. To do this, a hole of the same size is cut in this place in the plywood sheet and in the laminate panels. Then the ventilation hole is closed with a decorative cover in the color of the laminate. Usually such holes are located in inconspicuous places, so it will not create problems for you, and the old floor will “breathe” and will last for a long time.

If there are concerns that the load-bearing joists require strengthening or even replacement, a part of the board is cut out in places of maximum deflection of the old floor using a jigsaw. It is better to hold the jigsaw not vertically, but at a slight angle. In this case, the cut piece of board will have a narrowing downward, and it will be easy to simply put it in place.

The logs are inspected through the cut hole and their condition is determined. Repair of joists may be limited to driving in wedges to level them or additionally fixing the joists to the base with anchors. Rotten or seriously damaged joists must be dismantled, which will require removing the entire floor. New ones are installed in place of the old logs. An old wooden floor can be replaced with two layers of plywood. The thickness of the plywood sheets is selected depending on the load on the floor covering in the room.

Features of laying laminate flooring on a wooden floor

Laying the substrate

Various types of laminate underlays are available:

Manufacturers claim that the substrate is able to level the base under the laminate. This is an exaggeration. The substrate must provide heat and sound insulation. The underlay can compensate for minimal unevenness in a leveled old wooden floor or plywood base, but no more.

Important! The substrate is laid end-to-end, the joints are fixed with tape. This way it will not move when laying the laminate.

Laying laminate

We determine the installation method: diagonally, perpendicular or parallel to the light. Laying diagonally is more often used in narrow spaces - this is one way to visually expand them.

Typically, laminate is laid perpendicular to the window - in daylight, the joints between the panels will be less noticeable, but in the case of a wooden floor, you need to focus on the direction of laying the boards. On such a floor, the laminate is laid perpendicular to the floor boards to reduce possible deflection.

To work you will need:

- Jigsaw or hacksaw.

- Plastic wedges.

- Roulette.

- Square.

- Mallet and die (for Lock locks).

- Pencil.

The first row is laid horizontally from the corner. The panels are connected at their ends. In order to maintain the required gap of 10 mm between the panels and the wall, plastic wedges are used. The last panel in the row is cut with a jigsaw or hacksaw and laid in a row. You can start the next row with the remaining piece of the panel (provided that its length is more than 200 mm), the main thing is that the seams in adjacent rows do not coincide.

Advice. To give panel offsets a more accurate appearance, a technique such as “offset by a third of the board” is used. One third is cut off from the new panel, after which it is laid.

Laminate, as a finishing floor covering, is becoming increasingly popular due to its excellent performance characteristics, aesthetic appearance, simplicity and speed of installation.

1. Sanding is carried out if the difference is insignificant, and the issue can be resolved by removing a small layer of wood on a certain area of the floor, thereby ensuring an acceptable evenness of the surface.

2. An electric planer is useful when the local difference in the board covering in a certain place is more significant. But when using this tool, you need to make sure that the floor boards are of sufficient thickness and the heads of the nails or screws are deep enough.

Since the plane is capable of removing a fairly large layer of wood, level control is necessary after each passage along the boards. After carrying out such a procedure on areas of the floor that are too protruding, it is quite possible to achieve the desired result.

3. If the surface slopes strongly to one side, you can’t get by with just an electric planer, since the problem is not with the boards, but with the subsidence of the joists.

That's why , will have to dismantle the boards and inspect the joists and floor beams. Perhaps over time they have become unusable from time to time or damaged by insects or microorganisms. In this case, the logs and beams will have to be replaced with new ones. If they are in good condition, then you can raise the boards on them using wooden pads, also controlling the leveling process with a level. When the boards are placed on supports and the floor is level, the surface must be carefully scraped off.

The process of leveling with raising the floor is quite labor-intensive and lengthy, but it must be done. Otherwise, the base will not last long, which means that the boards will still have to be lifted and carried out soon renovation work, but this will already be associated with completely unnecessary procedures - dismantling the recently laid laminate.

4. Another process of leveling a wooden floor will require additional costs, since a plywood covering is laid on top of the boards. However, this method will help not only make the floor level, but also insulate it well. This method can be used if the floor and joists are strong enough.

The plank covering should also be checked by level, and in places where the floor is lower than the main covering, plywood or chipboard pads are fixed, and it may be necessary to use boards. If boards are used for leveling, they are nailed perpendicular to the base boards.

Sheets of plywood, 10-12 mm thick, are attached to the floor at a distance of 1-3 mm from the walls and screwed to the base using self-tapping screws. When using small sheets of material, they are laid with rows offset by half a sheet.

5. You can level a wooden floor using self-leveling self-leveling floor or screed. In this case, a waterproofing dense polyethylene film is laid on the plank surface. Its edges are lifted and secured to the walls. The film must create an airtight space, so its individual sheets are overlapped by 15-20 cm and secured together with waterproof tape.

- Next, an elastic damper strip is installed around the perimeter of the room, which will serve as a compensator for the screed in case of possible expansion of the material.

- Then, the surface is leveled, and in the area where the surface is much lower than the main coating, a beacon made of a metal guide is installed. Its height should correspond to the difference in floor height. The beacon must be fixed with plaster mortar. The guide cannot be screwed in with self-tapping screws, otherwise the tightness of the waterproofing will be compromised.

- Then, the solution is mixed and laid out on the surface in the area where the lowest point of the floor is located. The screed is leveled using the rule.

- If the floor difference is small, then it is quite suitable for pouring self-leveling floor. The special mixture is diluted into a homogeneous mass and poured over the waterproofing, leveling with a squeegee and rolling with a needle roller to remove air bubbles from the solution.

- After the poured composition has dried, the surface is again leveled. If it meets the requirements of horizontal alignment, you can proceed to further work. If it was not possible to achieve the required evenness, then another thin layer of self-leveling floor can be placed on top.

6. A wooden floor can be leveled using the recently popular dry screed method.

For this method, just like the previous one, you will have to make reliable waterproofing. In this case, it is needed not only to prevent moisture from penetrating the wooden surface, but also to prevent bulk material consisting of fine expanded clay from spilling into the floor cracks.

- Backfilling is done from the place where the lowest point of the surface level is located and you need to fill in more expanded clay there than will remain there after leveling.

- Then, on the rash they set beacons - guides, most often from a galvanized metal profile used for working with drywall. They are set in such a way that when the material is finally leveled, at the highest point of the screed, the expanded clay rises above the wooden covering by at least two to three centimeters.

- On top of the expanded clay embankment special gypsum fiber panels that are glued together and then screwed together with self-tapping screws. This creates a reliable, rigid surface for laying laminate flooring. In addition to the function of leveling, this material will also perform another function - it will become a good insulation for the floor.

Underlay for laminate

According to the technology, one of the types of substrates is laid under the laminate. It is necessary so that the covering lies flat, has a kind of soft shock-absorbing “cushion” and is sufficiently insulated. For these purposes, the following materials are used:

Foamed polyethylene;

Cork backing;

Linoleum;

Dornit.

In addition to the functions described above, the substrate softens the noise of steps on the surface of the laminate and protects it from mechanical damage both above and below due to its springiness.

- Cork backing has the highest qualities - it has recently become very popular. This environmentally friendly material has a number of special advantages over others - it is an excellent noise and heat insulator, even its thinnest layer can replace thicker polymer substrates.

It is easy to install, and laying laminate on it is easier than on other substrates, since cork mats do not bunch up and do not wrinkle. This material is produced in rolls and slabs, so you can choose a form that is convenient for work.

- Dornit is an environmentally friendly non-woven material, also called geotextile. It is made from polypropylene fibers, so it has good elasticity and can easily withstand heavy loads.

The material is not expensive in price, but it is mainly used for reinforcing road surfaces. It is also suitable as a substrate for laminate flooring, however, you need to know that dornite does not have any special sound or heat insulating qualities, but it is quite capable of muffling the sound of steps on the laminate.

- Foamed polyethylene is used not only as a substrate, but also as a full-fledged insulation, as it is produced in different thicknesses.

This is a rolled material, it is quite convenient to lay it, but to prevent it from gathering during the installation of the laminate, it is better to secure the strips with double-sided tape to the base. Polyethylene foam dampens noise well and has a soft spring when walking on it.

- If linoleum was laid on a wooden floor, then after leveling the surface it can be returned to its place and used as a substrate. It is also capable of insulating floors and creating sound insulation. When walking on laminate flooring in heels, the sound of footsteps will be partially damped.

Laminate panel connection system

Today, several types of laminate are produced to connect panels together - this can be a glueless locking or adhesive connection. The most popular laminate has a locking connection, which comes in two main types, usually called “Lock” or “Click”.

Lock system

Panels with the “Lock” connection system have a groove and a tenon located in the same horizontal plane. They are quite easy to connect - they are placed horizontally and the tenon is inserted into the groove. Then, on the other side of the panel, a flat and smooth wooden block is installed and, carefully tapping it, the two panels are finally connected.

"Lock" are essentially latch locks, they are more economical to purchase, but are not as strong in grip as "Click". In addition, if it is necessary to dismantle the surface, difficulties will certainly arise - the spikes easily break off. That’s why this system is being produced and is being used less and less lately.

Click system

“Click” locks have a special three-dimensional design and engage only when the panels are connected at a certain angle. They provide good strength to the butt joints, and no cracks form even after long-term intensive use of the coating. If circumstances force it, a laminated floor with such locks can be easily disassembled and then reinstalled in the old or another place.

This system of interlocking connections is currently used by almost all leading companies producing laminate flooring.

Adhesive laminate

Laminate laid with glue has an advantage over other systems in that such a connection forms a reliable, almost monolithic surface. This allows the material to be used in rooms with high humidity or in places where water is likely to get on the floor (for example, a kitchen).

- There are some inconveniences that may arise when installing the coating - this is the constant application of glue to the locking parts of the panel.

- If an adhesive laminate is laid, then after completion of the work it can be used only after ten hours.

- A laminate installed with glue cannot be dismantled without damaging it, so it will not be possible to reuse it.

- It is not recommended to use this material for covering heated floors, since the glue may dry out over time under the influence of elevated temperatures and the laminate will not stick to it. In addition, the glue can release unfavorable for the human body evaporation.

Laminate installation

- Laminate flooring begins from any angle. The first thing you need to do is cover the entire room or some area of it with a substrate, and you can start working on it. The next section can be laid only after the first one is almost completely filled with the installed laminate. The backing sheets are fastened together using special construction tape.

- The first row starts with a solid panel and is laid at a distance of 10 mm from the wall. In order to maintain the required gap, spacer wedges are inserted between the laminate panels and the wall. This provides an expansion joint necessary to prevent the surface from swelling due to thermal expansion of the coating.

- The first row is laid completely. If a part of the panel is to be laid at its end, then it is measured and cut using a jigsaw.

- The second row begins with half of the laminate panel and is also laid to the end. So continue further, the entire floor will not be finished. Thus, all odd rows start with a whole panel, and even rows -

- If the first row contains all the panels in one piece, and there was no need to add halves, then the second row you still need to start with half the laminate board and use the other half at the end of the second row. This is necessary in order to maintain the “bandaging” of the laminated boards in the rows. To save money, you need to use cut pieces from the panels, placing them at the beginning even

- Laminate flooring with click locks has characteristic feature installation They are inserted at a certain angle, and when rotated in one plane, they snap into place. Thus, no additional manipulations of tapping with a hammer are required.

- However, this also determines another important feature of the assembly of such a coating. During installation, it is necessary to completely assemble each next row in a separate strip, and only then connect it to the already laid laminate. Without an assistant, especially when large sizes premises, it is almost impossible to cope with this.

- After laying the last row, you can remove the spacer wedges installed along the entire perimeter of the covering. All that remains is to attach the baseboards. At the same time, you need to remember that the skirting boards are under no circumstances attached to the surface of the laminate - only to the wall!

Video: a short lesson on how to properly lay laminate flooring

It is not difficult to cover a wooden floor with laminate, the main thing is to choose a quality one material with the lock that will be most convenient for installation. In addition, it is very important to properly prepare the surface. If these conditions are met, then the work will proceed quickly without any particular difficulties.

- If the first row contains all the panels in one piece, and there was no need to add halves, then the second row you still need to start with half the laminate board and use the other half at the end of the second row. This is necessary in order to maintain the “bandaging” of the laminated boards in the rows. To save money, you need to use cut pieces from the panels, placing them at the beginning even

In this article we will talk about the experience of laying laminate flooring on a wooden floor in a panel house. It's about about budget renovations that everyone can afford.

This is what the floor looked like before the renovation...

The first problem that every resident of a panel house has encountered is the creaking of wooden floors. Here's why this happens: The floorboards are nailed to the joists, which have become loose over time, causing the floor to creak.

The next problem is a very uneven floor with large differences between the boards. To lay laminate flooring, such a floor must be leveled, and the maximum permissible height differences should not exceed 2 mm per 1.5 m.

To eliminate these problems, we decided to level the wooden floor using plywood. But if you just screw plywood on top of the creaking boards, then, of course, it won’t get any better. Therefore, you first need to strengthen the floor with screws.

We dismantle the old baseboard. If it is plastic, there will be no problems, but a wooden baseboard needs to be torn off with a pry bar or a nail puller. We pull out all the protruding nails and remove large protrusions with a plane. Before laying plywood, do not forget to thoroughly wash and vacuum the floor.

Preparing a wooden floor for renovation

Preparing a wooden floor for renovation Now it is important to determine at what height the wooden floor is raised above the slab; for this, 1-2 holes are drilled in the boards. You need to know the distance between the base and the boards to determine the size of the screws for the floor. Usually it is 8-10 cm, but on the first floor there are even 25 cm.

After raising the floor level, the door may not open: the thickness of the laminate with the backing is almost 1 cm + the thickness of the plywood (minimum 0.6 cm). If the door is old, then you can cut it without any problems with a hacksaw, simply by removing it from its hinges. And to trim a door with a laminated coating, be sure to place thick plywood underneath, otherwise chips will appear at the cut site.

Material calculation

Next you need to calculate how many screws you will need. To do this, we look at how many joists there are in the room (they can be found by nails or seen in a crack near the wall). Then we count the number of boards in width and multiply the resulting amount by the number of joists.

Each board is screwed with 1 screw to the joist, every 40-60 cm. For example, if there are 11 joists and 28 boards in the room, then you will need 308 screws + 10-20% for reserve.

It is better to screw the plywood every 15 cm; if less often, it will swell and dangle when walking. The length and width of the room are measured and the resulting amount is divided by 15 cm, and then the values are multiplied. For example, our room measures 3x5.6 m. Divide 3 meters by 0.15 = 20 pieces, divide 5.6 m by 0.15 = 38 pieces. Now we multiply 20 by 38 and get 760 pieces, + 10-20% for stock. For plywood, wood screws 25-30 mm thick and 3-3.5 mm thick are suitable.

Now we calculate how much laminate will be needed. To do this, you need to find out the dimensions of the room, and do the calculations in the store, because laminate panels have different parameters. Our room is 17 square meters. m. In one box there is a laminate with an area of approximately 2.6 square meters. m. Divide 17 by 2.6 = 6.53. We round up, which means we will need 7 boxes, and half the box will be in stock in case of defects.

This should be enough if you lay the laminate in the usual way: trimming costs are approximately 5%. If laying diagonally, the margin should be at least 10%.

When purchasing laminate, it is important that the delivery lot on all boxes is the same. In boxes with different batches, the shade of the design may differ. Also, the pack must be intact, otherwise the locks may be damaged.

Now we count the amount of plywood. We chose plywood with dimensions of 1.43x1.52 m, that is, the area of 1 sheet will be 2.17 square meters. m. We divide the area of the room (17 sq. m.) by the area of plywood and get 7.8 sheets. This means you need to buy 8 sheets of plywood. The thickness of the plywood must be at least 12 mm.

Strengthening boards with screws

So, all the materials have been purchased, let's start strengthening the floor with screws. There is an article on the site about what to do with a creaking floor in an apartment; it partially talks about this work.

Since the screws were difficult to insert into the wood, we first drilled holes about 70% of the length of the screw, and then used screws to tighten the boards to the joists.

We strengthen the floor in rows along the joists

We strengthen the floor in rows along the joists Of course, if you have a powerful screwdriver, you will be able to do this much faster without additional drilling. In our case, the cheapest Chinese screwdriver, which quickly sat down, so the whole job lasted for several days.

The main thing is to screw the boards tightly to the joists so that they do not dangle when walking.

Since the doors will soon be replaced, we are cutting down the slopes to install the plinth.

During work, it turned out that there was too much blowing from under the floor on the street side, so we had to seal the gap with foam. In this case, you need to moisten the surface with water before treatment, and also spray the foam after application, since the polymerization process of the polyurethane foam requires moisture.

There was a strong blow from the street from this gap

There was a strong blow from the street from this gap  It got so much better

It got so much better Leveling with plywood

To level the floor with plywood, place the sheet on the floor and screw it every 15 cm with screws. Don't forget to leave a small gap between the sheets and near the wall. The even position of the plywood sheets is controlled using a level. Sheets that require trimming are cut with a hacksaw or jigsaw.

To level the floor with plywood, place the sheet on the floor and screw it every 15 cm with screws. Don't forget to leave a small gap between the sheets and near the wall. The even position of the plywood sheets is controlled using a level. Sheets that require trimming are cut with a hacksaw or jigsaw.

Laying the substrate

The cat was scared...

The cat was scared... We chose the cheapest substrate, made of polypropylene. Before laying, vacuum the floor again.

We lay the backing with a reserve on the walls so that we can cut off the excess later, and glue it together with tape. The substrate should lie in one layer, joint to joint.

Laying laminate

Having finished preparing the floor, we begin laying the laminate flooring. Before this, you need to store the laminate indoors for several days (to adapt the material to the temperature and humidity of the apartment).

Laying begins from the corner of the room, preferably from the most visible place. However, there is a small nuance here: if the door opens into the room and no one plans to remove it, then they begin to lay the laminate from there, otherwise it will not be possible to lay the last row.

We start laying from the door

We start laying from the door It is best to place wide laminate joints along the light from the window, so the gaps will be less visible (over time they will increase).

Modern laminate is installed without glue, using the locking method. This type of flooring installation is called floating because it is not rigidly fixed to the floor, but lies freely on the underlay. During the change of season, the coating changes size slightly, so you cannot firmly screw the laminate to the floor. There are locks along the perimeter of the panel that connect if you insert one of the panels at an angle and then lower it.

To see how it works, watch the video tutorial:

Place the panel in the corner and join the next one on the short side. This is how we assemble the first row. The last panel will most likely have to be filed down. This can be done with a jigsaw or saw, but make sure the teeth are small, otherwise there will be chips on the laminated surface.

The first row is ready

The first row is ready The main rule when laying laminate flooring is to leave a gap of about 1 cm near walls, pipes, doors and other obstacles. However, you should not make a gap of more than 2 cm, because the thickness of the plinth will not be able to cover it.

A wedge is needed to support the same gap near the wall

A wedge is needed to support the same gap near the wall For ease of installation, stores sell a special kit for laying laminate flooring. It includes wedges of the same thickness, a mounting foot for installing the last row and a wedge of panels.

To additionally seal the seams, you can buy a special sealant paste and coat the locks with it before joining. However, in wet rooms it is better to use tiles or porcelain stoneware.

The second row is laid in the same way as the first, and then inserted into the previous one. To simplify the task, we recommend laying the panels as close to the lock as possible, so that you can then simply lift the entire row and click it into place. This is done by simply pressing the row at an angle.

To connect, insert the panels at an angle

To connect, insert the panels at an angle  Then we lower the panel so that the second row lies next to the first

Then we lower the panel so that the second row lies next to the first  We join adjacent rows with our hands

We join adjacent rows with our hands  As a result, the joint should not be visible

As a result, the joint should not be visible Some types of locks allow you to join the laminate not as a whole next to the previous one, but one piece at a time. For example, Quick Step laminate has universal locks: they can be inserted horizontally or at an angle. At the same time, there are Click locks that only hammer horizontally.

It is not necessary to immediately leave a gap between the first row and the wall. It will be more convenient to collect 3-4 rows, and then move them to the wall, and you can put something heavy on top. This is much easier, especially if the wall is not very smooth.

Another important feature is that the panels are laid in a checkerboard pattern. If the first row started with a whole laminate panel, then the second should start with half, and the third again with a full panel. This way the connections of the locks will be tighter, and the cost of cutting will be minimal.

Half the room is already readyThus, we lay the remaining rows of the laminate in a checkerboard pattern. When we reach the heating pipe, cut a round hole with a jigsaw or drill. Then we simply lay the scrap and press it with a plinth or glue it to liquid nails.

When we reach the last row, we need to file each panel to the width, taking into account the gap. Installation occurs in exactly the same way; press firmly on the panel at an angle.

The floor is almost ready

The floor is almost ready Installation of skirting boards

The plastic plinth with cable duct consists of two parts. The first is a wall mount, and the second is a decorative attachment that snaps on top. There is another type of fastening - first, metal brackets are attached, and then a plinth is put on them.

We drill holes for dowels approximately every 30 cm and fasten one part of the plinth. We fasten the main part, hide the wires, then put on the decorative attachment. For a beautiful connection, we use special components for the plinth: adapters, external and internal corners, plugs.

We put a special lining around the pipe to hide the gap (it costs about 50 rubles). In our case, the pipe was very close to the wall, so we had to trim the baseboard and saw off the lining, and then glue it with liquid nails.

Buy the plinth and all components together with the laminate. Otherwise, if there is a shortage of material, you will have to visit many stores before you can find the right color.

And the final touch is to attach the threshold to the door. It is needed to hide the height difference between rooms. The rules for laying laminate flooring require separating different rooms with a gap so that the coverings are independent. However, in practice, if the same covering is chosen for adjacent rooms, you can not use the threshold, but do everything without seams: it will be prettier and easier to clean. If some kind of defect later appears, it is more convenient to actually saw off the coverings in the doorway.

Floor repair cost

- Birch plywood 6 mm thick, 8 sheets – 2300 rub.

- Laminate Kronostar White Pear 31 class – 7 boxes. 1 sq. m. cost 235 rubles in Leroy Merlin. Total 4112 rub.

- Backing for polypropylene laminate – 1 roll, 2 mm thick, 25 m long – 320 RUR.

- Screws and dowels - about 600 rubles.

- Plastic plinth with cable channel 8 pieces, 2.5 m each - 150 rub.

- Piping around the pipe, connectors and corners for the plinth - 420 rubles.

- Threshold – 160 rub.

As a result, the amount is: 9112 rubles.

The cat clearly didn't like the new slippery floor

The cat clearly didn't like the new slippery floor - It is better to take thicker plywood; 6 mm is still not enough, so you should not skimp on this. Next time we would take plywood of at least 12 mm. If the floor is too uneven, then you need to lay plywood in 2 layers, with the joints offset.

- We advise you to choose screws that are not too thick or long, as they will be difficult to screw in.

- You cannot buy a soft substrate thicker than 3 mm; it will spring strongly when walking, and the floor will be pressed under you. To find out more detailed information, we recommend reading our article about.

- If the laminate is laid on a concrete floor, then before laying the backing you need to lay a layer of polyethylene for waterproofing.

- For productive work you will need a good screwdriver with a powerful battery. This way you will save a lot of time.

By spending a small amount of money on repairing the old wooden floor, we got rid of the squeak and made it smooth and pleasant to walk on. It took three days to prepare the floor for the laminate, and one day was spent on the installation itself.

Laminate is one of the most popular floor coverings today. It is used in both residential and commercial establishments. Laying laminate flooring on a wooden floor is done when it is necessary to hide the defects of the old plank covering, as well as when you want to simply update the interior.

According to experts, it is better to completely dismantle the old wooden floor, after which, to level the rough base, apply a concrete screed under the laminate. But since this process will require additional costs that may exceed the cost of the laminate, it is possible to lay the product directly on a wooden base, as well as using plywood or OSB as a substrate. Let's look at the first and second methods of installing laminate flooring on a wooden floor with all the details.

Tools and materials for working with flooring

1. Drill, jigsaw and screwdriver. Power tools allow you to increase the speed of installation, facilitating manual labor. 2. Hammer and mallet. Laying laminate flooring on a wooden floor simply cannot be done without them: hammer in nails, knock down the laminate, tap the boards. 3. Level and roulette. 4. Fiberboard or plywood. Used to level floors.

5. Nails or screws. Necessary for attaching a wooden “screed”. 6. Underlay for laminate. Purchased depending on the room.

Getting ready to lay laminate flooring

Before laying laminate flooring, you need to remember that the material must be left for some time in the room where it is intended to be used. This is done so that it adapts to the humidity characteristics of the room and does not warp later. This is especially important if you are planning to lay laminate flooring on a wooden floor. The fact is that wood is a rather capricious material. Indoors, the laminate is left sealed for approximately 48 hours. According to experts, it is best to place it in the middle of the room. The room where the laminate is “maintained” must have a temperature of at least 18 degrees and a humidity of no more than 75%.The feasibility of laying laminate flooring on a wooden floor

The answer to the question whether it is possible to lay laminate flooring on a wooden floor most often depends on the strength of the base. Most consumers who prefer laminate-based floor finishing doubt the possibility of installing slats on wooden floors and are thinking about dismantling the wooden covering. Of course, removing a wooden base takes a lot of time, and besides, this work is not only labor-intensive, but also dirty. However, it should be remembered that in some cases dismantling cannot be avoided. Thus, laying slats on wooden floors that are rotting or affected by fungi is unacceptable. Covering the damaged surface will not be able to stop the process of wood rotting, and after some time the laminate will also be affected by rotting.

An alternative to expensive dismantling works may be local replacement of the areas most affected by rotting, followed by the use of waterproofing materials. In this case, it is advisable to use moisture-resistant plywood sheets as a substrate.

Assessing the condition of a wooden floor

Laminated panels can be laid on wood floors only after a full range of measures has been taken to properly prepare the surface. Wood is a good base for laminate, but its condition must be suitable for the finishing work. Often, before installing laminate flooring, it is necessary to repair the wooden base. The most common defects are creaking floors as a result of drying out and surface deformation. In addition, repair work may be required if it is necessary to strengthen loose wooden floorboards of the base. Sometimes you have to use additional fasteners. You can identify the main irregularities using a building level. This method will allow you to correctly assess the volume of activities to level the base.Features of a wooden floor

The base for the laminate must be smooth, strong and rigid. These conditions must be observed so that the locking system is not damaged during operation. For example, if we lay laminate flooring on a wooden floor without preliminary preparation, this is not recommended, since the plank covering may have significant differences in height, individual boards may sag, which is considered unacceptable. Owners of apartments or houses where the old floor is made of wood often have a question about how to lay laminate flooring on a wooden floor and whether it can be done. It is possible to lay laminate flooring on such a base, the main thing is to carry out the correct preparatory work. Wooden bases are found quite often in rooms for various purposes. To prepare it for subsequent use, it is necessary to study it and, if there are any defects, eliminate them.

The first thing to remember is that wood is an unstable material; it is characterized by processes such as drying out and desiccation. During such movement, gaps may form between the boards, which will increase the load on the laminate locking system. Second: it is necessary to examine not only the surface of the wooden floor, but also its structure - beams, joists. If any defects are found, they must be eliminated, as they can further harm the floor covering. Next, we will consider the main methods of preparing a wooden base, since the preparatory processes are the main ones in the work. If you simply throw them away, then the whole arrangement will come to naught.

Preparing a wooden base for laying laminate flooring without plywood

In order to lay laminate directly on a wooden floor, you must ensure that the surface is in satisfactory condition:

Sometimes it is necessary to repair and strengthen the logs themselves, which “walk” under load - for this, beams or bricks are installed under the logs. Floorboards can creak due to friction against each other. To eliminate the grinding between them, graphite or talc is poured into the gap. Existing gaps are filled with putty. Next, to fully ensure that the wood is in good condition, you need to remove the old layer of paint with your own hands. The appearance of the tree should be close to the natural shade throughout the entire plane. If in some places on the floor the boards look dubious, it is recommended to test them for strength with an awl. The second way to identify rotten or rotten floorboards is to tapping the floor surface with a hammer. In this case, tapping on intact healthy wood will be heard loudly and clearly. While the muffled sound will be a serious reason for replacing old wooden elements with new ones. Even though rotten boards are still strong, you still need to replace them yourself, as the rot can spread to healthy parts over time. Treatment with an antiseptic composition and waterproofing of the wooden base will prevent their occurrence in the future. If grooves in the form of grooves are found on the floorboards, it is necessary to apply a bioprotective composition to the wood flooring, since their presence indicates contamination of the material with wood borers. An uneven wooden floor must be leveled; differences in its surface can be 1.5-2 mm/1m2. The way to determine how uneven the flooring is is to use a building level. In the absence of the specified measuring device, you can use a two-meter bar and a spirit level. If the height difference is not critical, an uneven floor can be leveled using a grinding machine, or with your own hands using a plane. The second method is too long scraping technology copes with the task at hand faster and more efficiently. The main thing is that before leveling the floor for the subsequent laying of the laminate, do not forget to recess the heads of the nails located above the surface deeper, which can cause the grinding equipment to fail. If your old wood floor is too uneven and sanding cannot solve the leveling problem, there is another way to make it as level as possible - by pouring. Pouring a wooden base for laying laminate is done by using a self-leveling screed, but not a self-leveling mixture, which is not used for wood. To level a wooden floor, compounds with fiberglass are used, due to which the materials firmly adhere to each other. Unlike standard solutions, fiberglass mixture is thicker and hardens faster. But before pouring, waterproofing in the form of a dense polyethylene film is laid on the wooden base. Waterproofing is arranged along the floor in such a way that its edges can be fixed to the walls around the perimeter of the room. The pieces of film are laid overlapping each other, with an allowance of 15-20 cm, the joints are glued with construction tape.

Leveling a wooden floor with plywood under laminate

The technology of leveling a wooden floor using plywood or OSB is a low-cost, but at the same time, effective way to make the base base ideal for laying laminate flooring. To find out which substrate will be better for laminate - OSB or plywood, you need to compare technical specifications both products. Sheets of plywood and OSB boards are materials of similar quality: the products are easy to process, have a durable structure and relatively high moisture resistance. At the same time, OSB boards are cheaper than plywood, but the appearance of the products does not allow them to be used for the construction of a finished floor.

Despite this, OSB is slowly displacing plywood products from the construction market, because the behavior of plywood during operation is difficult to guess, which cannot be said about OSB boards, which do not have the property of delaminating under atmospheric and mechanical influence. In addition, the modulus of elasticity during bending, compression and tension of OSB boards is an order of magnitude higher than that of plywood. Based on the above, we can conclude that OSB boards are the most suitable products that will not only level an uneven floor, but also extend its service life.

Rules for laying OSB boards on a wooden base

Basic rules for laying OSB boards on a wooden floor: as a substrate for laminate, it is necessary to use materials with certain parameters. For example, for a laminate with a thickness of 7 mm, you should not buy slabs more than 2 mm thick; for a thicker finish coating of 8-9 mm, the optimal substrate thickness is 3 mm. A thicker backing will sag slightly when pressed, causing the laminate's interlocking joints to become deformed. Installation of OSB boards on a wooden base is carried out by screwing them with screws or nailing them with rods of a certain length. The distance between fasteners is calculated by multiplying the existing slab thickness by 2.5. It is necessary to leave 5 mm technological gaps between the plates, which are subsequently filled with polyurethane foam. IN mandatory Waterproofing is installed under the substrate, preventing the formation of condensation that destroys the structure of the wood. The uneven transition at the junction of the plates is leveled with epoxy putty.Choosing a substrate for laminate

There are several types of materials used for laying laminate flooring. Cork backing- valued for its composition: it consists exclusively of natural materials, no chemical components. Does not rot, does not spread mold. Does not deform and retains its original appearance throughout its entire service life. Bitumen substrate- when laying laminate flooring on wooden floors in an apartment, you can also use thick paper in combination with bitumen: this material protects the laminate from moisture and is perfect for uneven floors.

Installing laminate flooring on a wooden floor

Here we come to the most important point, which requires attention and composure: every action will affect the final result, so be careful and strictly follow all the instructions described below. Installing laminate flooring on a wooden floor with your own hands can be done in several ways:click system

The workflow starts from any corner opposite front door: around the entire perimeter, along the walls, wedges (pieces of plywood) 1 cm thick are installed. This is necessary to create a wall gap so that the laminate can freely expand and contract later. 1. The very first panel is placed in a corner and pressed against the installed wedges. 2. We continue the row with the second panel, which joins the first at an angle of 20-30 degrees: pressing the ends tightly, using gentle pressure, click the lock and lower the laminate board.

3. We lay out the row until we hit the wall/door. The last panel is trimmed to fit the remaining gap. 4. The next row begins with the cut piece, this is how the checkerboard effect is created. 5. Along the length, the laminate is also snapped into an acute 30-degree angle.

Lock system

This method will answer the question of how to lay laminate flooring vertically and diagonally on a wooden floor. 1. The work process begins from the corner opposite the door. 2. The second panel is brought horizontally to the first panel (to the short end), inserted into the groove and hammered with a mallet. 3. Along the long end we match the already pre-assembled row to the existing panels.

4. Try to use a mallet or hammer with blocks, this reduces the risk of damaging the laminate.

Glued laminate

Another way that can answer the question of how to lay the flooring yourself, without special tools and skills. There are no special notes on installation with glue, but there are some points that are worth knowing in advance. The adhesive at the joints of the panels best isolates the base of the laminate from moisture, thereby extending the service life of the floor covering.

Before you can walk on such a floor, you must wait 10-12 hours at room temperature, without creating drafts. It is no longer possible to reuse such a surface: during dismantling, most of the panels will be damaged.

Maintenance and care of laminate flooring

1. Avoid getting excessive moisture at the joints of the panels. 2. Place something soft under the sharp corners of the legs of sofas and other interior items. 3. Monitor the humidity in the room: with sudden changes in temperature and increased dryness, the laminate may come apart, cracks will form, which will be problematic to eliminate, and you will have to disassemble the floor.Apartment renovation very often involves not only updating the interior decor, but also replacing the old flooring with a more modern one. Often, it is this stage of repair that becomes the most problematic. This issue is especially acute for owners of apartments in Khrushchev, where the floors are made of planks, because, if you look at it, there are not so many floor coverings that are compatible with laying on wood. In most cases, it is necessary to dismantle the wooden floor and then prepare for laying a new floor covering. But this procedure is not only lengthy, but also quite expensive, which pushes you to choose a coating that can be laid without removing your old plank floor. The best option in in this case is considered a laminate, which can be quickly and easily laid on any wooden base without resorting to the services of specialists. How to lay laminate flooring on a wooden floor in an apartment will be discussed further.

To assess the feasibility of using a laminated flooring for laying on a wooden base, it is necessary to conduct a full diagnosis of the latter, because very often a wooden floorboard is susceptible to fungus or mold, the influence of external factors can lead to surface deformation, sagging and squeaks. Therefore, you should pay attention to the following points when checking the plank base to make sure whether laminate flooring can be laid on a wooden floor:

- dryness - this indicator should be given special attention, since rotting of the surface or fungal infection of the board will continue after the installation of the lamellas. Over time, this problem will spread to the installed laminate flooring;

- hardness - the strength of the wooden base under the laminate, another important factor that should not be ignored. This determines how long the new coating will last without flaws or deformation;

- evenness - care should also be taken to ensure that the surface of the previous coating is as even as possible. A deviation of 2 mm per 2 m length is allowed. Otherwise, the laminate lamellas will begin to creak, and the locking joints will be subject to deformation.

Detailed requirements for working with wooden floors for laying laminate can be found by watching the video. If the base still has flaws that can be eliminated, then laying the laminate on a wooden floor is done only after they have been eliminated.

If there is a large amount of damage to the plank floor, it is still recommended to completely dismantle it and then fill the area with a concrete screed.

How to lay laminate flooring on a wooden floor

The technology for laying laminated slats on a plank base consists of several stages of preparatory work and laying the laminate itself directly. Before laying laminate flooring on a wooden floor, you need to prepare all the necessary materials and tools. Then you should evaluate the condition of the base surface and, if necessary, work to eliminate any deficiencies identified on it. At the next stage, the selected substrate is laid, on which the selected type of laminate is laid.

When starting to prepare the necessary tools and materials, priority should be given to the choice of the laminate itself, which consists of several layers and can have a different base.

The laminated board has the following structure:

- overlay – a protective layer that prevents damage to the lamella from different types influences: chemical, biological, mechanical;

- decorative layer – a material that sets the color design of the board, its pattern. The reliability of the layer is ensured by melamine impregnation;

- the base is a board made of high-density wood fiber materials. The quality of the panels and, accordingly, the scope of application depend on the density of the base. The basis can be MDF or chipboard;

- stabilizing layer - protects against moisture seepage, as it contains paraffin or melamine paper.

The type of laminate is selected depending on the scope of its application and the traffic flow of the room.

Materials required for use:

- laminate of the corresponding class from 31 to 33;

- substrate;

- fastening materials for wood;

- mastic;

- timber

To work you will need a set of the following tools:

- carpenter's hammer;

- square;

- mallet;

- ruler;

- jigsaw;

- construction vacuum cleaner;

- nail puller;

- saw;

- level or level;

- hacksaw;

- perforator;

- brushes;

- screwdriver;

- scraping machine.

Having equipped yourself with this set of tools and materials, you can move on to the next stage of work.  Tools for laying laminate flooring

Tools for laying laminate flooring

Diagnostics and repair of the base

Before laying laminate flooring on a wooden floor, it is necessary to conduct a thorough inspection of it and, if such a need arises, repairs, which you can do yourself. What points you should pay attention to and how to eliminate the identified shortcomings are discussed below:

- wooden floors are leaky or rotten. If the material is slightly damaged, you can lay the same board by simply turning it over. A place that has been affected by mold or rot must be treated with a special compound. If the tree has deeper damage, it is better to completely replace the plank area;

- If the floors creak or slightly sag in certain areas, it is necessary to additionally secure the boards using self-tapping screws or nails. Their caps should be driven deeply into the wooden surface. Otherwise, the metal that will protrude beyond the surface will damage the power tools used in the future - a scraper or electric planer;

- if the boards “play” under your feet along with the lags, then it is necessary to fix the lags themselves. To do this, the lag is attached to concrete base with an anchor, having previously drilled it;

- small gaps or cracks between the boards can be filled with putty. Large gaps can be eliminated using polyurethane foam;

- in case of significant subsidence of the floors or differences exceeding the norm, it is necessary to level the frame itself, having first removed the boardwalk. To eliminate minor shortcomings, support wedges are used, which are attached to the logs. If there are significant height discrepancies, a complete replacement of the frame is necessary.

Preparing a wooden floor for repair

Preparing a wooden floor for repair  Scroll the floor in rows along the joists

Scroll the floor in rows along the joists Upon completion of all preparatory work, the base for laying laminated boards should be perfectly level, which can be checked using a level or level. If you place laminate flooring on an uneven wooden floor, a squeak will inevitably appear; the life of the floor covering will be short, since the load will cause the lamella locks to separate, thereby compromising the integrity of the surface.

Leveling a wooden floor

It was already mentioned above that the final result of the work directly depends on how smooth the base surface is. Therefore, the issue of leveling the plank base should be approached with all responsibility, because even a slight unevenness will subsequently cause creaks or breakages. There are several most common ways to level a surface on a wooden base.

Sanding a wooden floor - for minor unevenness of the wood base, you can use the sanding method or a similar surface treatment with an electric planer. This method will give the desired result with minor deviations from the standard height difference, which should not exceed 4-6 mm per 1 m2. For ease of use and easier control of grinding, it is better to divide the floor surface into several squares. Upon completion of all work, it is necessary to carry out a control check of the surface with a level and carefully remove sawdust and dust using a vacuum cleaner. If the irregularities occupy a small space, then you can get rid of them using sandpaper or by hand sanding.  Floor sanding

Floor sanding

Using a self-leveling mixture - if the floor is very old, and there is no desire or opportunity to replace it with a new one. Before pouring, you should carry out preparatory work: clear the floor of paint, fill voids, if any, with putty, prime the dried surface, mark the floor using a level, fill with the prepared mixture and level the surface.

Leveling a wooden floor with PVA-based putty. The use of such mixtures is more acceptable when working with large surfaces. Screeding with such mixtures consists of several successive stages: installing beacon strips, filling the gaps with wet sawdust and diluted mixture, checking the evenness of the surface, eliminating defects. If necessary, you can apply several additional layers of putty about 2 cm thick. A new layer is poured only on the dried previous surface, which requires time.  Sealing cracks and cracks with putty

Sealing cracks and cracks with putty

Leveling with plywood - plywood under laminate on a wooden floor is the most common method of leveling the base plane. The grade of plywood should not be lower than 4/4, and the thickness should not be less than 15 mm. Plywood must be pre-impregnated with special compounds that will prevent rapid deterioration of the material. The final result will depend on these indicators. Laying plywood on a wooden floor under laminate begins with leveling the subfloor. To do this, wedges are installed under the logs. Then the plywood is laid with full horizontal control. If necessary, slats are placed under the chipboard sheets. Then the plywood is attached to the frame base joint to joint. You can learn more about the types of floor leveling with your own hands by watching the following video.  Leveling with plywood

Leveling with plywood

Laying underlays under laminate

For additional leveling of the floor, a special waterproofing material is used - a substrate, which occupies the space between the sub-leveled floor and the laminate. The substrate can be laid using either an adhesive mixture or without additional fastening. In the second case, the joints are fixed with tape. The optimal material thickness is 3 mm. Wooden floors must be thoroughly cleaned of dust and small particles before laying the underlay.  Rolled backing

Rolled backing

The substrate serves the following purposes:

- enhancing heat and sound insulation;

- preventing friction of the laminate on wooden floors;

- increasing structural strength;

- additional leveling of the base layer.

For work, use a substrate made of the following materials:

- polyethylene foam;

- cork;

- bitumen sheet;

- polyurethane foam.

To cover a wooden base, it is better to use a substrate made of natural materials.  Bonding the substrate at the joints

Bonding the substrate at the joints

Laying laminate

Before laying laminate flooring on a wooden floor, it is necessary for the laminated slats to acclimatize. To do this, they are kept indoors for 2-3 days. This procedure helps the material come into balance with the environment.

Before you begin work on finishing the floor area, you need to figure out how to properly lay laminate flooring on a wooden floor and what determines the method of placing the slats. The laminate can be laid perpendicularly or parallel to the window, which is the light source, and diagonally. The diagonal placement of the slats contributes to the visual expansion of the room. Perpendicular masonry helps hide the joints.

Flooring work must begin with marking the floor, which is then used to measure the distance and calculate the number of boards to be laid. At this stage of work, it should be taken into account that the next laid laminated row must shift by a distance of at least half the length of the lamella, which creates the necessary mismatch of the seams. Let's look at how to lay laminate flooring on a wooden floor using different installation methods. Laying the first row Displacement of seams  Laminate lock padding

Laminate lock padding

Click system

A relatively new and easiest-to-install installation method, which allows you to quickly and efficiently lay slats on a wooden floor with your own hands. Laminate with Click lock begins to be laid from the far corner in rows, leaving a gap of 10 mm between the wall and the first row with the installation of special wedges. This procedure helps to avoid deformation of laminated panels due to temperature changes or changes in humidity in the room. The planks are joined by connecting the lamella locks at an angle of 20-30 degrees and then clicking them by pressing the surface with force. The Click connection system allows you to dismantle the required section of the floor for repair work.

Lock system

Laminates with this system begin to be laid from the corner located farthest from the doorway. The lamellas are joined horizontally. To do this, the tenon of one lamella is inserted into the groove of the already laid panel and tapped until completely fixed with a rubber cue. A long row with full fixation is pre-laid. It is necessary to create a temperature gap of 3-5 mm between the wall and the floor. To lay the last row, the lamella is cut to fill the entire remaining space. It is better to tap not at the end of the laminate, but to use a buffer block for this purpose. This way you can avoid damaging the surface of the laminated board and deforming the lock.

Glued laminate

The most labor-intensive method of laying laminated boards, therefore this type of laminate is very rare. This masonry method is relevant for rooms with high humidity. The panels are connected using the tongue and groove method. The ends of the laminated boards are coated with excess glue and combined with the locks of the next board. To lay the second row, the first lamella is cut in half, which allows you to start laying with offset seams. For better fixation of the flooring, you can use tape. The finished surface can be used after no less than 12 hours. Thematic video will allow you to clearly understand all the nuances of working with laminate.

Installation of skirting boards

Upon completion of the work on laying laminated panels, it is necessary to carry out the final stage - installation of skirting boards. In the case of a laminate floor, any type of baseboard must be attached to the wall. Dowels, screws or glue are suitable for this.

Skirting boards can be used in all types and modifications - wooden, flexible, plastic or MDF, solid or with a cable channel. The main rule in this case is the organic combination of the new floor with the baseboard.

As you can see, laying laminate flooring is not such a difficult task. It is important, before laying laminate flooring on an uneven floor, to carry out all necessary work to eliminate deficiencies, and then the coating will delight its owners for a long time with durability and reliability.  Fastening the baseboard

Fastening the baseboard

Video about laying laminate flooring on a wooden floor

The video explains in detail how to install laminate flooring on a wooden floor.

B1 in English what level?

B1 in English what level? Managing verbs in German - German online - Start Deutsch

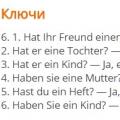

Managing verbs in German - German online - Start Deutsch Conjugation of the verb haben (to have) in the present tense

Conjugation of the verb haben (to have) in the present tense