LLC independent examination Volgograd. Assessment of the quality of ceramic bricks by external characteristics. Determination of brick grade by compressive and bending strength

Brick: how much does it cost to build a house?

Brick: how to choose

Foam concrete

Varnishes and paints - what do the letters in the name mean?

Paint and varnish materials

What is siding?

Polyurethane foam

Porcelain tiles

Concrete

Ceramic tiles

Bulk materials

Cementing materials

Precast concrete and concrete products

Wall materials

Building blocks made of cellular concrete

Noise insulation

Application of self-leveling screed

Brick: construction features

Knauf

Knauf: new technologies in repair, or what is cheaper?

Gipsell (Gipsel)

Brick brands. Directory.

Strength. BrandStrength– the main characteristic of brick is the ability of the material to resist internal stresses and deformations without collapsing.

Brick brand– this is an indicator of strength, designated “M” with a digital value. The numbers show what load per 1 sq.cm. can withstand brick. For example, grade 100 (M100) means that the brick is guaranteed to withstand a load of 100 kg per 1 sq.cm. The brick can have a grade from 75 to 300. The most common bricks on sale are M100, 125, 150, 175.

How to find out what brand of brick you need? For example, for the construction of multi-storey buildings, bricks of at least M150 are used. But for a cottage of 2–3 floors, “one hundred square meters” (that is, M100) is enough.

Frost resistance

Frost resistance– the ability of a material to withstand alternate freezing and thawing in a water-saturated state.

Frost resistance (denoted “Mrz”) is measured in cycles. During standard tests, a brick is immersed in water for 8 hours, then placed in water for 8 hours. freezer(this is one cycle). And so on until the brick begins to change its characteristics (weight, strength, etc.). Then the tests are stopped and a conclusion is made about the frost resistance of the brick.

For Moscow construction projects, you need to use bricks with frost resistance of at least 35 cycles. Therefore, large factories try not to produce bricks with frost resistance below 35 cycles. But on the market you can still find bricks with frost resistance of 25 and even 15 cycles (usually brought from warm regions). He has low price, this attracts buyers (and sellers try not to talk about “features”).

In general, the brand of brick for the future home should be determined by a specialist.

Determination of strength, brand of brick, hardness, uniformity, density and ductility of various composite materials

Our organization determines the strength of cement concrete, brand of brick in masonry, mortars and other composite materials using the shock pulse method according to GOST 22690 during technological control of products and structures, inspection of buildings and structures, at construction sites and hydraulic structures. We determine the strength of bricks, hardness, uniformity, density and plasticity of various materials

Technical characteristics of bricks

Strength Brand

Strength– the main characteristic of a brick is that, under certain conditions and limits, it can withstand loads or other influences that cause internal stress in it without destruction. The strength of a brick is characterized by its “M” brand and is indicated with a numerical value. The numbers show what load per 1 sq.cm. can withstand brick. Based on strength, bricks are classified into grades: M75,100,125,150,175,200,250,300.

Brick brand– this is an indicator of strength, designated “M” with a digital value. The numbers show what load per 1 sq.cm. can withstand brick. For example, grade 100 (M100) means that the brick is guaranteed to withstand a load of 100 kg per 1 sq. cm. The brick can have a grade from 75 to 300. The most common bricks on sale are M100, 125, 150, 175.

How to find out what brand of brick you need? For example, for the construction of multi-storey buildings, bricks of at least M150 are used. But for a cottage of 2–3 floors, “one hundred square meters” (that is, M100) is enough.

Frost resistance

Frost resistance – the ability of a material to withstand alternate freezing and thawing in a water-saturated state without signs of destruction. The frost resistance of a material is characterized by the number of cycles of freezing (at a temperature not exceeding -18 degrees) and thawing (in water), which it can withstand without reducing strength and weight loss or the appearance of external damage specified in GOST for the corresponding material. Based on frost resistance, materials are divided into grades: F15,25,35,50,100, etc. For example, the frost resistance grade of brick F15 means that samples taken from a batch of bricks can withstand at least 15 freeze-thaw cycles without the appearance of external damage (chips, peeling of the surface, etc.). For Volgograd construction projects, you need to use bricks with frost resistance of at least 35 cycles. Therefore, large factories try not to produce bricks with frost resistance below 35 cycles.

Frost resistance (denoted “Mrz”) is measured in cycles. During standard tests, a brick is immersed in water for 8 hours, then placed in a freezer for 8 hours (this is one cycle). And so on until the brick begins to change its characteristics (weight, strength, etc.). Then the tests are stopped and a conclusion is made about the frost resistance of the brick.

But on the market you can still find bricks with frost resistance of 25 and even 15 cycles (usually brought from warm regions). It has a low price, which attracts buyers (and sellers try not to talk about “features”).

In general, the brand of brick for the future home should be determined by a specialist.

In a word, we do not recommend chasing cheap bricks with frost resistance of 25 or even 15 cycles. For construction in Volgograd and the region, use Mrz 35 brick. Or better yet, 50.

Brick Density

A physical quantity determined by the mass of a substance (or material) per unit volume. The average density is determined by the ratio of the mass m (kg) of the material to the entire volume Vest (m3) occupied by it, including the pores and voids present in it: m / Vest. Because average density Since the material, just like thermal conductivity, is inversely proportional to porosity, it can serve as a characteristic of the thermal conductivity of the material and be used as the main characteristic (grade) of the thermal conductivity of the material.

Thermal conductivity of brick

The ability of a material to transfer heat through its thickness from one surface to another if the temperature of these surfaces is different. It is characterized by the thermal conductivity coefficient “λ”, W/m °C.

Brick porosity

The degree of filling of the volume of material with pores. Measured in %. Porosity is the main structural characteristic that determines such material properties as water absorption, thermal conductivity, acoustic properties, frost resistance, strength, etc.

Brick brand

Determination of brick strength according to GOST 8462-85

Determination of the compressive strength of wall materials according to GOST 8262-85 applies to ceramic, silicate bricks and stones. To determine the compressive strength, 10 samples are taken from a batch of bricks. Samples taken in a wet state are kept in the laboratory for 3 days or dried in an oven at a temperature of 105 C for 4 hours. The grade of brick for compressive strength is established from the results obtained during compression and bending tests according to Table 6 of GOST 530-2007. To determine the compressive and bending strength, 5 samples of one batch of bricks are used. When conducting compression tests, it is allowed to use brick halves that have passed bending tests. The compressive strength of concrete stones is determined on the whole stone. The surfaces of ceramic bricks and stones are prepared before the compression test by leveling their supporting surfaces cement mortar. It is allowed to use pads made of technical felt, rubber-fabric plates, cardboard and other materials to level the surface. Samples from sand-lime brick and stones obtained by semi-dry pressing are tested without surface preparation. Preparation for tests. Samples are measured with an error of up to 1 mm. Each linear dimension of the sample is calculated as the arithmetic mean of the measurement results of two midlines of the opposite surfaces of the sample. Determination of the compressive strength of bricks. The sample is placed on the center of the lower platen of the press and pressed against the upper platen. The load on the sample should be applied evenly and continuously, ensuring its destruction in 20-60 seconds. after the start of the test. The tensile strength of the sample is determined by the formula: Rсж=P/F, where P is the greatest load on the sample, and F is the area of the transverse sample. If the thickness of the test sample is 88 mm, then the test result is multiplied by a factor of 1.2. The compressive strength in a batch of bricks is determined as the arithmetic mean of all samples with an accuracy of 0.1 MPa. Determination of the bending strength of bricks. The sample is mounted on two press supports. The load is applied in the middle of the span and distributed evenly across the width of the sample. The load on the sample must increase continuously at a rate that ensures its destruction within 20 - 60 s after the start of testing. The tensile strength in bending is determined by the formula Rben=3Pl/2bh2. The tensile strength in bending of samples in a batch is calculated with an accuracy of 0.05 MPa, as the arithmetic mean value of the test results of a specified number of samples.

- Our instrument base

Our specialists Independent Expertise ready to help both physical and legal entities in carrying out construction and technical examination, technical inspection of buildings and structures, brand of brick in masonry.

Do you have unresolved questions or would you like to personally communicate with our specialists or order independent construction expertise, technical inspection of buildings and structures, determination of maki bricks, all the information necessary for this can be obtained in the “Contacts” section.

We look forward to your call and thank you in advance for your trust.

→ Ceramic bricks and stones

Determining the brand of brick by strength

The grade of bricks and stones is established based on the results of testing them for strength in compression and bending for all types of bricks and only in compression for stones, carried out in accordance with GOST 8462-85.

Tests are carried out on dry samples. Before testing, wet samples are kept for at least 3 days indoors at a temperature of (20±5)°C and dried for 4 hours at a temperature of (105±5)°C.

Samples selected for testing according to appearance, presence of defects and appearance, must meet the requirements of the standard (GOST 530-95).

The compressive strength of a brick is determined on samples of two whole bricks or two halves. Bricks are divided into halves by sawing or splitting. Bricks (or halves) are laid in beds on top of each other. The halves are placed with the parting surfaces in opposite directions.

Tests of ceramic stones are carried out on whole samples.

The supporting face (bed) of plastic molded bricks and stones always has significant deviations from the plane, which does not ensure uniform distribution of the load over the entire plane of the sample. Therefore, when preparing samples for testing, the surfaces are leveled, which in the design and, accordingly, during testing are located perpendicular to the direction of the compressive load.

The standard recommends connecting parts of brick halves (or whole bricks) and supporting surfaces of bricks and stones and leveling them with cement mortar. Composition of the solution according to GOST 8462-85: cement grade not lower than 400 - May 1. h; sand with a particle size of no more than 1.25 mm - May 1. h; W/C - 0.40…0.42.

The production of a sample for testing bricks is carried out as follows. The bricks or its halves are completely immersed in water for 1 minute. After this, a sheet of paper, a layer of mortar no more than 5 mm and the first brick or half of it are placed on a horizontally installed plate (metal or glass) with a thickness of at least 5 mm. Then again a layer of mortar and a second brick (half). Excess solution is removed, and the edges of the paper are folded over the side surfaces of the sample. The sample is kept in this position for 30 minutes. After this, the sample is turned over and another supporting surface is leveled.

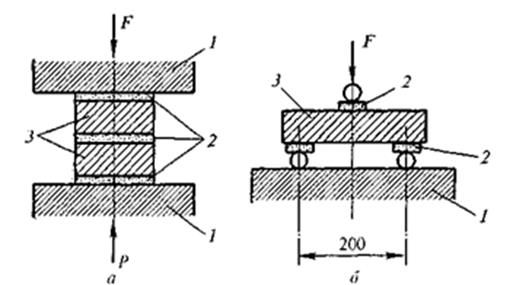

General view The sample prepared for testing is shown in Fig. 1, a. The deviation from parallelism of the aligned supporting surfaces of the sample, determined by the maximum difference between any two of its heights, should not exceed 2 mm.

Rice. 1. Scheme of tests of bricks for compression (a) and bending (6) when determining its strength grade: 1 – prescent slab; 2 – leveling material; 3 – brick

The alignment of the supporting surfaces when making a ceramic stone sample is carried out in the same sequence.

After manufacturing, the samples are kept for 3 days at a temperature of (20±5)°C and a relative air humidity of 60...80% to harden the cement mortar.

Samples of semi-dry pressed brick are tested “dry” without leveling their surfaces with cement mortar.

Bricks and stones of plastic molding may be tested on samples prepared by other methods:

a) the supporting surfaces are leveled by grinding;

b) leveling is done with gypsum mortar;

c) using pads made of technical felt, rubber-fabric plates (conveyor belts), cardboard and other materials.

Specimens made using gypsum mortar are tested no earlier than 2 hours after molding.

The standard stipulates that during arbitration inspections and consumer inspections, samples of bricks and ceramic stones are prepared by connecting and leveling them according to the above method, i.e. using cement mortar.

The actual testing of samples is carried out in the following sequence. Samples are measured with an error of up to 1 mm to calculate the area of its working surface. The cross-sectional area of the sample £ (m2) is calculated as the arithmetic mean of the areas of the upper and lower faces.

Vertical axial lines are applied to the side surfaces of the sample, with the help of which the sample is installed in the center of the press platen. The most suitable for testing bricks is a press with a maximum force of 500 kN (50 t).

The sample is pressed with the upper plate of the press and the oil pump is turned on. The rate of loading must be such that destruction of the sample occurs 20...60 s after the start of testing.

The compressive strength of the tested batch of bricks and stones is calculated with an accuracy of 0.1 MPa as the arithmetic average of the test results of all five samples.

To determine the brand of brick, another test is carried out - bending.

The flexural strength is determined on the whole brick according to the standard scheme.

In places of support and application of load, the surface of plastic molded bricks is leveled with cement or gypsum mortar, grinding or using spacers.

Before testing, the height and width of the samples at the point of application of the load are measured with an error of 1 mm. The dimensions are calculated as the arithmetic mean of the measurement results of two midlines on opposite faces of the sample.

When testing samples for bending, a special device is used, fixed on the bottom plate of the press. The device consists of two rollers (movable and fixed), on which the brick to be tested is installed. A roller is installed on top along the center line (along the leveling layer), transmitting the load from the top plate of the press. The entire installation must be strictly centered. The diameters of the rollers used are 10…20 mm; material - steel.

Bricks with blind voids are installed so that the voids are located in the stretched (lower) zone of the sample.

The tensile strength in bending of samples in a batch is calculated with an accuracy of 0.05 MPa, as the arithmetic mean value of the test results of the number of samples established by the standard. When calculating the tensile strength in bending, specimens whose tensile strength deviates from the average tensile strength of all samples by more than 50% (one in each direction) are not taken into account.

The strength of brick is the basis on which the quality of our structure and its durability depend. The strength of the brick is what you need to pay attention to when choosing a brand of brick for a small utility structure or for building your own house.

The idea came up to build a house

If we decide to build a real house that will last for hundreds of years, then, first of all, we will turn to the most suitable building material for these purposes - . Why? Because of its high strength. This is confirmed by thousands of brick houses that have stood for more than 100 years. Brick houses successfully withstand all external natural factors: rain, frost, heat and wind. He is not afraid of either fungi or pests. Brick houses are synonymous with safety and durability. And all this is thanks to the main factor - the strength of the brick. One of the most important properties of brick is strength. The strength of brick is characterized by its grades: M50, M75, M100, M125, M150, M175, M200, M250 and M300. What do these numbers mean? They show the permissible load per square centimeter of brick, in kilograms. Strength itself is the ability to resist stress and deformation without collapsing. For example, M125 brick. This means that the brick will withstand a load of 125 kg per 1 square centimeter. This means that with a brick area of 300 square centimeters, to destroy our brick we will need a load of 37,500 kg, i.e. 37.5 tons. At the same time, it must be remembered that the bending strength of a brick is only 20% of the compressive strength. You should also take into account such a parameter as the strength of the brickwork. Which becomes a maximum of 40 - 50% of the strength of the brick itself. Because it is impossible to lay the mortar perfectly evenly and tightly over the entire area of the brick. This is where additional bending and compression forces arise.

Different brands of bricks are used for different structures

If we want to build one or two storey house then the M100 brand of brick will be enough for us. If we are talking about multi-story construction, then we should already be talking about the M200. During the design process, design organizations calculate the grade of brick based on the initial data. Although when calculating the thickness of walls in low-rise buildings, the thermal conductivity of the brick comes first. How is the strength of a brick tested? In the laboratory on a large press. A brick is placed under the press, and a second one is laid on it. The unit is started. The press presses on the brick with a gradual increase in pressure, which is displayed on the pressure gauge. At the moment of brick destruction, sensor data is recorded. At large enterprises, each batch of bricks is tested for strength. In the artisanal conditions of small workshops, such tests are not carried out. And you can only build sheds or other auxiliary premises such as a toilet with bricks produced in such handicraft industries.

Let's briefly look at the strength of different types of bricks.

Sand-lime brick is made from a sand-lime mixture (ratio 9:1) and steamed in an autoclave. It is produced quickly and relatively cheap. The strength of such a brick will be a maximum of M200. Red ceramic is produced by firing a clay mixture with various additives. The result is a rocky structure. The brand M300 already appears in these bricks. Hyper-pressed brick, its composition includes cement, limestone, various slags, shell rock and the like. During the first month of storage, the brand of such brick may already become M350. Clinker bricks, there are already grades up to M 1000. They are produced in the same way as simple ceramics, only at a higher temperature, which causes deeper sintering of the particles. With such bricks you can build not only houses, but also sidewalks with road surface. It should be noted that the strength grades of imported bricks are the same as those of domestic ones, but imported bricks have a wider range of colors.

The strength grade of brick is determined by the values of the ultimate compressive and bending strengths, and of stone - by the value of the ultimate compressive strength. The strength limits of products in compression and bending should not be less values, indicated in table 3.

The strength grade of products must be no lower than: hollow brick and stone (except large-format stone) - M100, large-format stone - M35, solid brick for load-bearing walls– M125, for self-supporting walls – M100.

Strength grade of bricks intended for construction chimneys, must be at least M200.

The bending strength is determined by testing hydraulic press a whole brick laid flat on two supports located at a distance of 200 mm from one another (Fig. 4).

Three strips of cement paste 20-30 mm wide are laid along the length of the supports on the brick: two strips - in places where they rest on the lower supports, one - under the support transmitting the load. Samples after 3-4 days of hardening are tested.

Bending strength MPa, kgf/cm² is determined by the formula:

– distance between supports, m; b– brick width, m (cm); h– height (thickness) of the brick in the middle of the span, m (cm).The compressive strength of a brick is determined on samples of two whole bricks or two halves. Bricks are divided into halves by sawing or splitting. It is allowed to determine the compressive strength on brick halves obtained after testing it for bending. Bricks (or halves) are laid in beds on top of each other. The halves are placed with their interfaces in opposite directions and glued together with cement paste made from Portland cement of a grade no higher than M400 (sand with a particle size of no more than 1.25 mm; W/C = 0.40...0.42).

The preparation of a sample for testing bricks is carried out as follows. The bricks or its halves are completely immersed in water for 1 minute. Then a sheet of paper, a layer of mortar no more than 5 mm and the first brick or half of it are placed on a horizontally installed plate and pressed lightly, then again a layer of mortar and the second brick or half of it. The same amount of cement paste is applied to the upper surface of the second half of the brick. Excess solution is removed, and the edges of the paper are folded over the side surfaces of the sample. The sample is kept in this position for 30 minutes. After this, the sample is turned over and another supporting surface is leveled.

After their manufacture, the samples are kept for 3 days at a temperature of (20±5)°C and a relative air humidity of 60...80% to harden the cement mortar.

Samples of semi-dry pressed brick are tested “dry” without leveling their surfaces with cement mortar.

Bricks and stones of plastic molding can be tested on samples prepared by other methods: a) supporting surfaces are leveled by grinding; b) leveling is done with gypsum mortar; c) using pads made of technical felt, rubber-fabric plates (conveyor belts), cardboard and other materials.

Specimens made using gypsum mortar are tested no earlier than 2 hours after molding.

Ultimate compressive strength MPa (kgf/cm²) is determined by the formula:

where F is the breaking load, N (kgf); S – area, m² (cm²).

Rice. 3. Scheme of tests of bricks for compression (a) and bending (b) when determining its strength grade: 1 – press plate; 2 – leveling material; 3 – brick

The results obtained are compared with the data given in table. 3.

Table 3. Strength limits of products in compression and bending

The test results are entered into Table 4.

Table 4. Test results of ceramic bricks

Security questions:

1. What are ceramic materials? Where are they used?

2. What quality indicators do ceramic bricks and stones have?

3. How is the quality of brick assessed?

4. What are the dimensions of a single, modular, thickened brick?

5. What are the dimensions of a hollow ceramic stone?

6. How and by what formula is the compressive strength determined when bending a brick?

Literature:

1. ST RK 530-2007 “Ceramic brick and stone. General technical conditions".

2. Belov V.V., Petropavlovskaya V.G., Shlapakov Yu.A. Laboratory determination of the properties of building materials. – M.: IASV, 2004.

3. Popov L.N., Popov N.L. Laboratory work in discipline " Construction materials and products": Tutorial. – M.: INFRA-M, 2005. – 219 p.: ill. ( Vocational education)

4. Lukin E.S., Andrianov N.T. Technical analysis and control of ceramic production. – M.: Stroyizdat, 2004. – 272 p.

5. Mikulsky V.G. and others. Construction materials (materials science and technology): Textbook. – M.: IASV, 2004, 2007. – 594 p.

Comparative characteristics of the main types of economic systems

Comparative characteristics of the main types of economic systems Submit a corrective personal income tax return 3

Submit a corrective personal income tax return 3 A detailed list of documents for registration of privatization of an apartment, as well as the procedure for obtaining them

A detailed list of documents for registration of privatization of an apartment, as well as the procedure for obtaining them