Brick house calculator. How to calculate facing bricks

Brickwork is one of the most common methods of constructing load-bearing structures.

Brick walls have a number of advantages, but at the same time their cost is much higher than many others building materials.

To optimize costs and draw up estimates, it is important to make an accurate calculation brickwork- calculate how many bricks are needed to build a building.

The more accurately you measure, the more accurate your calculations will be.

The more accurately you measure, the more accurate your calculations will be.

The entire calculation procedure is not particularly difficult and fits into a couple of simple mathematical formulas. But before you count the brickwork, you should make a number of measurements. And the more carefully they are carried out, the more accurate the final results will be.

First of all, it is necessary to correctly determine which type of brick is best suited in a particular case. There are several varieties of this building material on the modern market.

Adobe

Organic filler reinforces brick

Organic filler reinforces brick This type of brick is made from unfired clay and various fillers: chopped straw, reeds, shavings, etc. It is usually made in an artisanal way: clay is mixed with additives and briquettes are formed from it, which are not fired in an oven, but simply dried in the sun.

Organic fillers play a reinforcing role, preventing the clay briquette from falling apart during construction and operation. The main advantage of adobe is its low cost and ease of production, which you can set up on your own plot without any problems.

Due to imperfect production technology, which does not guarantee the strength of the material, adobe brick is prohibited by SNiP for use in the construction of residential and public buildings. Its main area of application is one-story outbuildings, garages, and fences.

Chamotte

This type of brick is used for the construction of structures subject to thermal stress.

This type of brick is used for the construction of structures subject to thermal stress. It's a fire brick. It is made from a special type of clay - chamotte and has a yellow color. It often contains coarse mineral fillers, so its surface may have a granular structure.

Due to their ability to withstand high temperatures (up to 1500 C) for a long time, fireclay bricks are used for the construction of stoves, fireplaces, chimneys, and the creation of thermal insulation screens.

The cost of refractory bricks is quite high, so it is not economically feasible to use them in the construction of load-bearing walls.

Silicate

Silicate varieties do not tolerate moisture well

Silicate varieties do not tolerate moisture well Unlike other varieties, the basis sand-lime bricks It is a mixture of lime and silicates. Because of this, they have a light gray tint. They are formed by wet pressing without subsequent firing.

Sand-lime bricks have increased hygroscopicity - the ability to absorb moisture, so they are not recommended for use in the construction of buildings that will be operated in conditions of high humidity: when constructing walls of basements, ground floors, etc.

Ceramic

Ordinary solid brick is well suited for the construction of load-bearing walls

Ordinary solid brick is well suited for the construction of load-bearing walls The largest and most common type of brick today. They are made from pressed clay and fired in special ovens at a certain temperature. All production technology and their technical specifications are strictly regulated by construction standards and GOSTs. Ceramic brick is divided into three main groups - ordinary, facing and clinker.

Due to the low strength of facing bricks, they cannot be used for the construction of load-bearing walls and when laying fireboxes and chimneys of stoves and fireplaces.

Calculation of the amount of material

To correctly calculate the amount of brick required for a wall, a number of factors should be taken into account. These are the linear dimensions of the brick itself, the area of window and door openings, the thickness and area of the walls, the width of the masonry joints.

Before calculating the amount of material, it should be taken into account that up to 10% of the brick will inevitably be “broken”.

These are irretrievable losses that occur during transportation, loading and unloading of materials and directly during the construction process, so the calculated volumes should always be multiplied by this coefficient, that is, by 10%.

Standard sizes

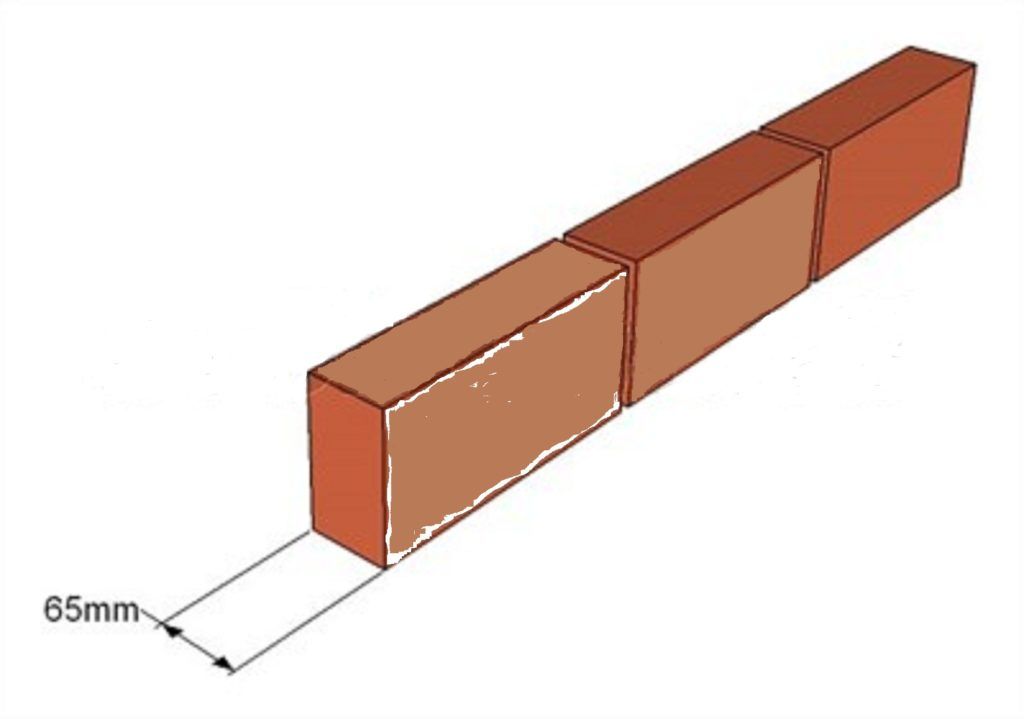

Standard sizes Standard brick sizes regulated by Russian GOSTs are:

- length – 25 cm;

- width – 12 cm;

- height – 6.5 cm.

This is the so-called single or standard brick. Construction backfill, fireclay, silicate bricks, as well as most facing bricks, have this size. In addition, the material is produced in non-standard, large sizes - “one and a half” and “double”.

One and a half brick, unlike the standard one, has a greater height with equal length and width.

- length – 25 cm;

- width – 12 cm;

- height – 8.8 cm.

The double brick has the following linear dimensions:

- length – 25 cm;

- width – 12 cm;

- height – 13.8 cm.

Eurobricks

Eurobricks In addition to the above, you can find so-called “Eurobricks” on the domestic building materials market.

This is material produced according to EU standards and imported to us from abroad. “Eurobricks” come in two main types:

- NF (standard): length - 24 cm, width - 11.5, height - 7.1.

- DF (thin): length – 24 cm, width – 11.5, height – 5.2 (optionally – 5 or 6.5 cm).

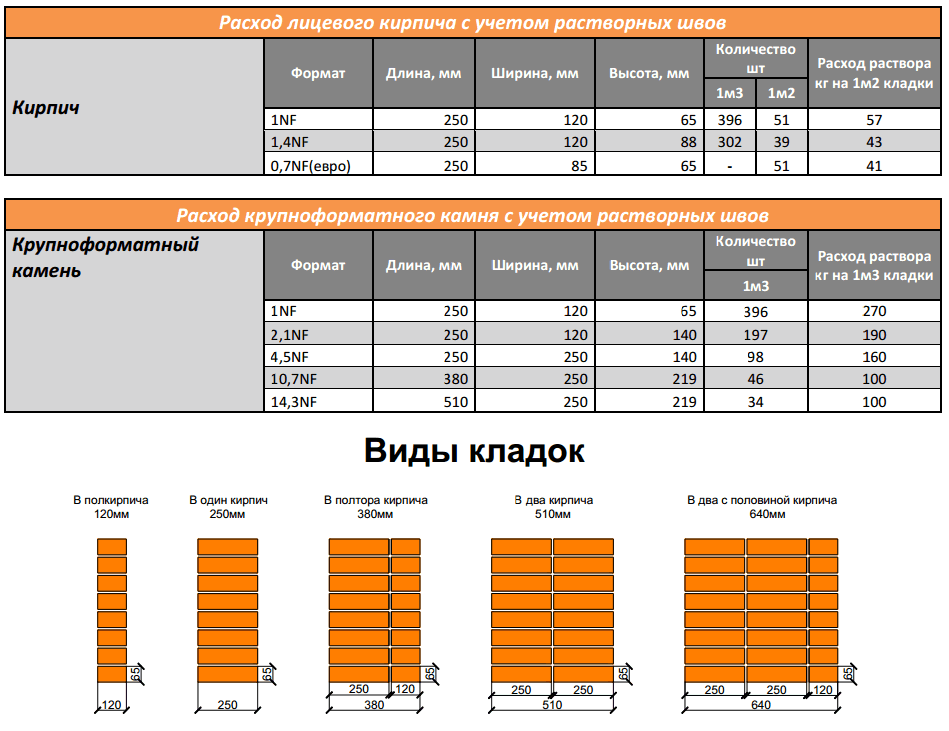

When calculating the number of bricks in a masonry, in addition to their linear dimensions, the thickness of the masonry mortar joints is also considered. The thickness of a standard seam is 1 cm, so another 0.5 cm should be added to the length and width of each brick. For more information about brick formats, see this video:

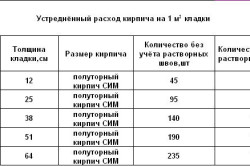

The table shows the number of bricks contained in 1 sq.m. masonry depending on its thickness.

Wall thickness and area

These parameters are key when calculating the required amount of materials. Before calculating the volume of brickwork, linear measurements of the walls should be taken: height, length and thickness. According to SNiP standards, the thickness of load-bearing walls can vary from 12 to 64 cm.

These parameters are key when calculating the required amount of materials. Before calculating the volume of brickwork, linear measurements of the walls should be taken: height, length and thickness. According to SNiP standards, the thickness of load-bearing walls can vary from 12 to 64 cm.

Masonry with a larger wall width is not used due to economic infeasibility: the cost of 1 m3 increases disproportionately, and the technical characteristics of the wall do not improve dramatically.

The area of the walls is calculated using a simple formula. The length is measured along the entire perimeter and multiplied by their height. After this, you can directly begin to calculate the volume of the masonry.

Calculation procedure

The number of bricks is calculated using the following algorithm.

The number of bricks is calculated using the following algorithm.

- All walls are divided into several groups depending on their thickness.

- A building design is taken and the area of all walls of the future building is calculated: external load-bearing walls and internal partition walls. In this case, the area of walls with different thicknesses should be calculated separately.

- Then the thickness of a particular group of walls is taken (half a brick, a brick, etc.) and multiplied by their area accordingly. Thus, we get the total “dirty” volumes of all the walls of the building.

- The next step will be to find the volume of all door and window openings. To do this, we measure their width, height and thickness - the latter indicator depends on which wall the opening is located in.

- Subtract the total footage of all openings from the total volume of the walls. As a result, the volume remains “clean”, that is, the brickwork itself.

- The volume of one brick is calculated by multiplying its length by width and height. Using a simple calculator, you can calculate that one cubic meter of masonry contains about 512 “standard” bricks with dimensions of 25 x 12 x 6.5 cm: 1 m3: 0.198 m3 = 512 pieces.

- Don't forget about the masonry mortar. Its share in the total volume of the wall can be no less than 15 - 20%. That is, from the previously obtained number, you can safely “throw away” about a hundred bricks. As a result, it will take approximately 400 of them to build 1 m3 of wall + 10% will be added to the “battle”. Finally, you need to multiply this amount by the final volume of the masonry and find how many total bricks will be needed to build the building. For more details about the calculations, watch this video:

As can be seen from the article, calculating the number of bricks needed to erect a structure is not so difficult. It is important to carefully make all measurements according to the building design. After this, simply substitute the resulting dimensions into the appropriate formulas. With the help of accurate calculations, you can avoid such troubles as excess, or, conversely, shortage of material.

Before starting any construction, including the construction of a plinth, you need to decide on the required amount of building materials and calculate the bricks for the plinth. After all, you must admit, it will not be very pleasant if, in the midst of construction, it turns out that there is not enough material. This will not only stop the entire construction process, but will also increase its cost due to additional transportation.

To perform such calculations, there is a special calculator for calculating bricks for a plinth, however, you can perform this operation yourself. Next we'll look at how to do this.

General information

Before you take up a piece of paper and a pen, or a calculator for calculating a brick for a plinth, let’s consider what it is this part designs. So, the basement is that part of the building that encloses the space between the foundation and the floor. It is also called the above-ground part of the foundation ().

When calculating the base, it should be borne in mind that it performs a number of functions:

- Protects the walls of the house from atmospheric precipitation, such as rainwater, melting snow, dew, and also prevents capillary suction, i.e. protects against moisture coming from the ground. If its design is not high, then the wall will become damp and, as a result, become covered with mold.

- It takes on the mechanical influences exerted by the buried soil inside the house.

- Takes on the load from the walls of the house.

Therefore, it is very important to perform a foundation calculation. Experts say that its height should be greater than the maximum height of snow cover over the past few years. As for the maximum height of the structure, there are no restrictions.

If you decide to build a building with a basement floor with your own hands, then the height can be made larger for comfortable use of the room.

Advice! A house with a high base looks more elegant and solid than one with a low base.

Material calculation

What parameters do you need to know?

So, in order to calculate the number of bricks per plinth, you need to know the following data:

- The length of the structure is determined by summing the lengths of all walls. For example, if a 10x8 house is being built, then the length of the walls is 10x2+8x2=36 meters.

- The thickness of the structure.

- Height of the base.

- Material size. The parameters of a standard solid product are 250x120x65 mm.

These same parameters will need to be entered into the calculator for calculating bricks for the plinth if you decide to get the result this way.

Pay attention! For the base you can only use a solid block. Sand-lime double brick M 150 is also suitable.

Determining the amount of building material

As an example, we find out the amount of material for a base one meter high, with masonry in one block, i.e. 0.25 m and house size 10x8 m ().

The instructions look like this:

- First of all, you need to convert all dimensions into meters for ease of calculation. As a result, the block dimensions will be 0.25x0.12x0.065m. The length of the structure, as we have already found out, will be 10x2 + 8x2 = 36 meters.

- Next, based on the given thickness, length and height of the walls, you need to calculate the volume of the masonry; to do this, we perform the following steps - 36x0.25x1 = 9 cubic meters.

- Then you need to find out the volume of one product - 0.25x0.12x0.065 = 0.00195 cubic meters.

- Now we divide the total volume of the walls by the volume of bricks, the result is 9/0.00195~4616 pieces. Accordingly, knowing the amount of material, you can find out what the cost of building the structure is.

The photo shows the laying of the plinth for calculating the material

If the base has openings, then their volumes must be subtracted from the total volume of the masonry. For example, the size of a window opening is 0.8x1x0.25 m. In this case, the volume will be equal to 0.8x1x0.25 = 0.2 cubic meters.

If there is only one window opening, then the volume of the masonry will be reduced to 9-0.2 = 8.8 cubic meters. If there are more openings, then, naturally, their volume should also be subtracted. To double-check the accuracy of the calculations, the calculator will also tell you how many bricks are needed for the base, if, of course, you have a computer and the Internet at hand.

Advice! You need to purchase materials with a small reserve, taking into account possible defects or damage during transportation.

There is also another way to perform the calculation:

- First of all, you need to determine how much material is located in one row of masonry. To do this, the length of the base should be divided by the width of the block, the result is 36/0.12 = 300 pieces.

- Then you need to find out the number of such rows. To do this, the height of the structure must be divided by the height of the block 1/0.065 = 15.38 rows.

- Then, by simple multiplication, we find out the required amount of material - 15.38 * 300 = 4614 pieces.

I must say that above we looked at the simplest calculations, if you need to get more exact result, then you should definitely take into account the thickness of the seam, which is usually about 10 mm. If you feel unsure, you can also seek help from specialists.

Advice! Since the base bears a large load, and the durability of the entire house depends on its strength, the masonry must be reinforced after every four rows. In this case, the seams must be carefully filled with mortar and the use of cracked blocks must be avoided.

Conclusion

To calculate the required amount of building material, of course, the easiest way is to use a brick per plinth calculator, however, if you only have a pen and paper at hand, then, as we have seen, it will not be difficult to perform this operation yourself. The main thing in this matter is attentiveness; in addition, do not be too lazy to double-check the result several times ().

For more information on this topic, watch the video in this article.

- What you need to know to calculate

- Calculation method for load-bearing walls

- Installation of jumpers over openings

The need to calculate brickwork when building a private house is obvious to any developer. In the construction of residential buildings, clinker and red bricks are used; finishing bricks are used to create an attractive appearance of the outer surface of the walls. Each brand of brick has its own specific parameters and properties, but the difference in size between different brands is minimal.

The maximum amount of material can be calculated by determining the total volume of the walls and dividing it by the volume of one brick.

Clinker bricks are used for the construction of luxury houses. It has a large specific gravity, attractive appearance, high strength. Limited use due to the high cost of the material.

The most popular and in demand material is red brick. It has sufficient strength with relatively little specific gravity, easy to process, low impact environment. Disadvantages - sloppy surfaces with high roughness, the ability to absorb water at high humidity. Under normal operating conditions, this ability does not manifest itself.

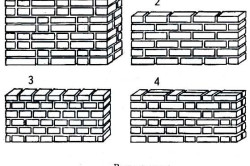

There are two methods for laying bricks:

- tychkovy;

- spoon

When laying using the butt method, the brick is laid across the wall. The wall thickness must be at least 250 mm. The outer surface of the wall will consist of the end surfaces of the material.

With the spoon method, the brick is laid lengthwise. The side surface appears outside. Using this method, you can lay out half-brick walls – 120 mm thick.

What you need to know to calculate

The maximum amount of material can be calculated by determining the total volume of the walls and dividing it by the volume of one brick. The result obtained will be approximate and overestimated. For a more accurate calculation, the following factors must be taken into account:

- masonry joint size;

- exact dimensions of the material;

- thickness of all walls.

Manufacturers quite often, for various reasons, do not maintain standard product sizes. According to GOST, red masonry bricks must have dimensions of 250x120x65 mm. To avoid mistakes and unnecessary material costs, it is advisable to check with suppliers about the sizes of available bricks.

The optimal thickness of external walls for most regions is 500 mm, or 2 bricks. This size ensures high strength of the building and good thermal insulation. The disadvantage is the large weight of the structure and, as a result, pressure on the foundation and lower layers of masonry.

The size of the masonry joint will primarily depend on the quality of the mortar.

If you use coarse-grained sand to prepare the mixture, the width of the seam will increase; with fine-grained sand, the seam can be made thinner. The optimal thickness of masonry joints is 5-6 mm. If necessary, it is allowed to make seams with a thickness of 3 to 10 mm. Depending on the size of the seams and the method of laying the brick, you can save some of it.

For example, let’s take a seam thickness of 6 mm and a spoon laying method. brick walls. If the wall thickness is 0.5 m, you need to lay 4 bricks wide.

The total width of the gaps will be 24 mm. Laying 10 rows of 4 bricks will give a total thickness of all gaps of 240 mm, which is almost equal to the length of a standard product. The total area of the masonry will be approximately 1.25 m2. If the bricks are laid closely, without gaps, 240 pieces fit in 1 m2. Taking into account the gaps, the material consumption will be approximately 236 pieces.

Return to contents

Calculation method for load-bearing walls

When planning the external dimensions of a building, it is advisable to choose values that are multiples of 5. With such numbers it is easier to carry out calculations, then carry them out in reality. When planning the construction of 2 floors, you should calculate the amount of material in stages for each floor.

First, the calculation of the external walls on the first floor is carried out. For example, you can take a building with dimensions:

- length = 15 m;

- width = 10 m;

- height = 3 m;

- The thickness of the walls is 2 bricks.

Using these dimensions you need to determine the perimeter of the building:

(15 + 10) x 2 = 50

3 x 50 = 150 m2

By calculating the total area, you can determine the maximum amount of bricks for building a wall. To do this, you need to multiply the previously determined number of bricks for 1 m2 by the total area:

236 x 150 = 35,400

The result is inconclusive, the walls must have openings for installing doors and windows. Quantity entrance doors may vary. Small private houses usually have one door. For buildings large sizes It is advisable to plan two entrances. The number of windows, their sizes and location are determined by the internal layout of the building.

As an example, you can take 3 window openings per 10-meter wall, 4 per 15-meter walls. It is advisable to make one of the walls blank, without openings. The volume of doorways can be determined by standard dimensions. If the dimensions differ from the standard ones, the volume can be calculated using the overall dimensions, adding to them the width of the installation gap. To calculate, use the formula:

2 x (A x B) x 236 = C

where: A is the width of the doorway, B is the height, C is the volume in the number of bricks.

Substituting standard values, we get:

2 x (2 x 0.9) x 236 = 849 pcs.

The volume of window openings is calculated similarly. With window sizes of 1.4 x 2.05 m, the volume will be 7450 pieces. Determining the number of bricks per temperature gap is simple: you need to multiply the length of the perimeter by 4. The result is 200 pieces.

35400 – (200 + 7450 + 849) = 26 901.

You should purchase the required quantity with a small margin, because errors and other unforeseen situations are possible during operation.

Before starting the construction of any facility, it is necessary to draw up its design and calculate the approximate consumption of materials. – this is a serious cost item, so its quantity needs to be known as accurately as possible. The online brickwork calculator allows you to make all the necessary calculations, taking into account the type of material, the thickness of the joints and the configuration of the walls.

Brickwork in one brick

The bricks in the masonry are laid in a certain order, which is called dressing. This is necessary so that after the mortar hardens, the wall of individual elements acquires the strength of a monolithic structure. Bricks are made to standard sizes, in accordance with the generally accepted modular construction system.

When calculating, you need to know the volume of the masonry. Therefore, you have to make a drawing that shows the dimensions of the walls and openings, then make simple but time-consuming calculations. Calculating “on the knee” is fraught with unforeseen errors, which then result in a lack of material, or, even worse, in excess and overspending of money. The calculator calculates the amount of bricks for building a house much more accurately and faster than an experienced estimator.

Brickwork calculator

An online calculator helps you calculate brickwork walls quickly and easily. This process is very important, because brick houses have always been and continue to be popular, and in order to build a house from brick, you will need to calculate in advance the amount of material that needs to be purchased. You can do it yourself or resort to the help of professionals, but then you should prepare for the fact that you will have to do a lot of scrupulous calculations.

Basic calculation rules

In order to build high-quality brick walls or at least several partitions, it is not enough to take into account only the parameters of their height and width. An important role in in this case has a masonry scheme, the type of which will affect the thickness and strength of the walls being built and, ultimately, their resistance to bends and cracks.

Before you begin calculating materials for constructing the walls of your future home, you will need to decide on the type of brick that you plan to use in construction. In addition, it is necessary to calculate the total area of brick walls, as well as window and door openings in the house under construction.

If the future house does not exceed 2-3 floors in height, then special attention to strength calculations is not required. If you wish, of course, you can use special formulas or tables with ready-made calculations, which are given in technical printed or online sources. However, the data contained in SNiP has the greatest reliability. This abbreviation stands for “building codes and regulations”, and this document contains the most reliable technical calculations in various construction areas, including regarding brickwork of external walls and internal partitions (SNiP II-22-81). In addition, design standards and work organization issues can always be found in another technical collection called ENiR (uniform standards and prices). In this case, information about brickwork is contained in the “Stone works” section.

What should you consider first?

As already mentioned, for a two-story house, bricks of grade 100 and 150 are quite sufficient, but for walls with openings, you will still need to check the tables, because they are considered weakened. So, when calculating the thickness of internal load-bearing walls, it is important to consider what type of floors will be laid between floors and how the load from the slabs will be distributed.

For large and tall buildings, as a rule, a technological standard map is formed, which describes practical recommendations and indicator tolerances for workers who will do brickwork for this facility.

It is worth recalling that the sizes of standard bricks differ only in thickness and are divided into single, one-and-a-half and double. Despite the fact that a single brick looks the most advantageous, one-and-a-half or double bricks allow you to quickly complete the construction of the wall and achieve savings on mortar.

Any of the listed brick sizes can be laid in several ways, depending on the thickness of the walls provided for the future building. For example, the thinnest walls will be half a brick, and in this case the thickness of the walls will be about 120 mm. This method is suitable for constructing partitions inside a building, and this width of the walls is quite enough to provide good sound insulation with a relatively small mass. A wall with one brick thickness will be 250 mm, one and a half - 380 mm. This is enough to build, for example, an internal load-bearing wall or a loaded column.

The most justified in the conditions of our latitudes for construction country house there will be walls of two bricks, while the thickness of such a wall (510 mm) is enough to distribute the load of the floors, and the thickest is considered to be a wall of 2.5 bricks (640 mm).

How to calculate the amount of bricks for a building under construction?

Obviously, the required amount of brick will depend on which masonry scheme is chosen for the construction of the walls. The easiest way is to calculate the amount of material for the thinnest wall. To obtain the desired result, it is enough to divide the wall height indicator by the corresponding indicator for a row of bricks, multiplied by their number in this row. But this method of calculation is not suitable for walls that involve several rows of bricks.

Two methods are used to calculate the amount of material: taking into account the thickness of the seam between the bricks and without it. The latter is used if they want to play it safe and there is an opportunity to dispose of the bricks remaining after the construction of the main building somewhere, because, as a rule, with this method of calculation the excess material is at least 20%.

Pre-calculated data can be found in the tables of the technical documents. So, for 1 sq. m of masonry for a single brick (65x120x250 mm), taking into account horizontal (12 mm) and vertical (10 mm) joints, the data will be as follows:

- for half-brick masonry, the number of bricks will be 51 pcs. per 1 sq. m;

- when laying in one brick - 102 pcs. per 1 sq. m;

- one and a half bricks - 153 pcs. per 1 sq. m;

- for laying two bricks you will need 204 pcs. per 1 sq. m;

- for masonry of 2.5 bricks - 255 pcs. per 1 sq. m.

The number of bricks per cubic meter of masonry is 394 pcs. But this is tabular data that is universal. If you want to calculate the amount of material individually for your construction, then this can be done independently.

First you need to measure the perimeter of each of the external walls and multiply this figure by the height. From the area data obtained in this way, you will need to subtract the size of all door and window openings. After this, the net area of the external walls is multiplied by the thickness of the brickwork, thus obtaining the volume of brick in cubic meters.

Then the volume of bricks for the internal partitions is calculated and all data is summed up. It should be remembered that some of the bricks may be damaged during transportation, so when ordering the material you should make a small reserve for unforeseen expenses.

For greater clarity, you can use an example calculation for a one-story brick house with a wall height of 3 m and a length of 8 and 10 m, respectively. The doorway is 1x2 m, and there are 3 window openings. - 1.2x1.5 m. The thickness of the walls is two standard single bricks, and the thickness of the seam between the bricks is 5 mm.

So, to calculate the number of bricks per 1 sq. m you need to add another 0.5 cm to the original brick dimensions. It will look like this: (0.12+0.005)x(0.065+0.005)=0.00875. Thus, the number of bricks will be: 1/0.00875x2=229 pcs. Now this figure should be multiplied by the total area of the masonry: 229x100.6 = 23037.4. To be on the safe side, you need to add 1.5-2 thousand bricks above this amount, and the final figure will be about 24.5 thousand bricks.

I must say that modern technologies allow you to use a special calculator to accurately calculate not only the amount of brick, but also mortar. In this case, parameters such as the height, length and thickness of the walls and the dimensions of window and door openings are entered.

We repair brickwork

Sometimes it happens that you need to calculate the amount of brick not for the construction of a new building, but for the restoration of damaged sections of walls. After all, no matter how durable this material is, the masonry can still suffer over time from exposure to natural factors, shrinkage of the foundation or other reasons. In this case, the calculation is carried out in exactly the same way as for a building under construction, with the only difference being that the area of the area being replaced is, as a rule, not too large.

It is very important to find out what exactly causes the cracks to appear in order to act correctly to eliminate them. So, if the cracks are explained only by the influence of atmospheric phenomena, this is one thing, but if the cause is violations in the technology during the construction of the building or errors in calculations regarding soil displacements, then the approach to solving the problem will be completely different.

If the damage is not too great and is limited to the appearance of a crack, then repairs to the brickwork can be carried out as soon as it becomes clear that the crack is no longer growing. To understand this, just cover the cracks with paper and monitor until the tears stop.

The smallest cracks (no more than 5 mm wide) can be covered with cement solution after dust and crumbs have been swept out of the crack, and the inner surface of the crack has been slightly moistened with a spray bottle. Medium cracks (5-10 mm wide) need to be covered with the same cement mortar, but adding a small amount of fine sand to it. And the widest cracks (more than 1 cm) will require a serious approach to their elimination.

In some cases, you can also use polyurethane foam, filling the gap with it, and after a few days, cutting the frozen foam to a depth of 2 cm, you need to cover this gap with cement mortar.

If the repair work was carried out inside the building, then after the mortar has dried, the walls are primed and the final finishing of the walls is carried out using plaster or wallpaper.

But in case of significant damage it is required major renovation walls made of brick, in which it is necessary to completely relay the brick along the entire depth of the façade of the house. Such restoration of brickwork in individual places will require first removing the destroyed bricks and cleaning the seams from the old mortar, after which a section of new masonry is laid in their place. In this case, the area located above the destroyed area is temporarily strengthened with the help of special beams, which are removed only 7-10 days after completion of the repair work. If the entire thickness of the masonry needs to be repaired, then fastenings are installed both outside and inside the building.

It should be taken into account that when restoring a large area, the outer bricks are first replaced, after them the bricks are laid in the middle, and the intermediate components are replaced last.

After renovation work Once completed, the walls are finished on the outside using façade plaster or stone, so that new and old areas of masonry do not bring disharmony into the overall appearance of the building.

Related posts:

Nature calendars series “The world around us”

Nature calendars series “The world around us” Methods for converting a complex drawing Method for replacing projection planes

Methods for converting a complex drawing Method for replacing projection planes Why do you dream about a closet - interpretation of sleep

Why do you dream about a closet - interpretation of sleep