Facade masonry made of colored bricks. What tools will you need? What quality of mortar is needed for brickwork?

- What tools will you need?

- Varieties decorative masonry

- Features of masonry

- Rusts, protruding parts and fastening

- Features of external decorative masonry

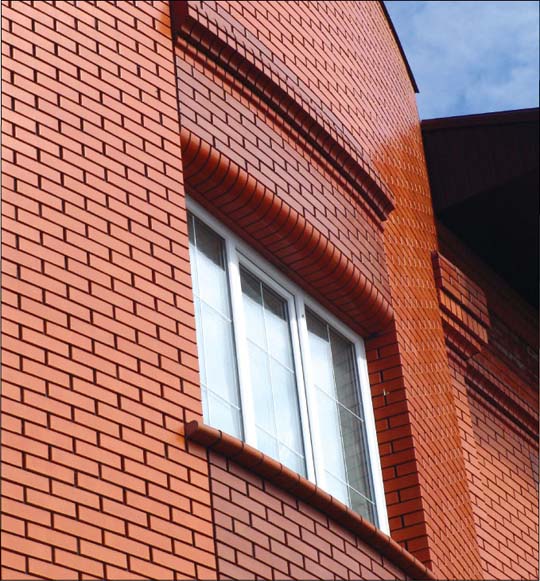

Brick laying may seem like a simple and not labor-intensive process if you stick to the basic rules and don’t think about more interesting design solutions for this process. However, some people choose this type of front brick cladding of the house as decorative masonry. With its help, you can get very interesting geometric shapes that will make the appearance of the building more expressive and place the necessary accents in it.

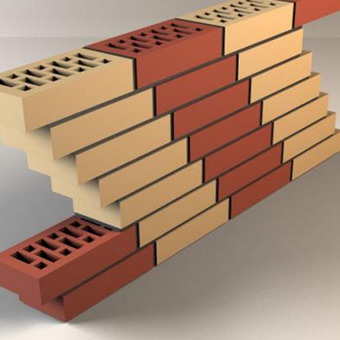

This type of masonry is almost no different in its technology from the usual one. The only difficulty in it is the specific placement of the brick. So, it can be placed flat, edgewise or even in a checkerboard pattern. In this case, it is possible to use bricks of different sizes.

What tools will you need?

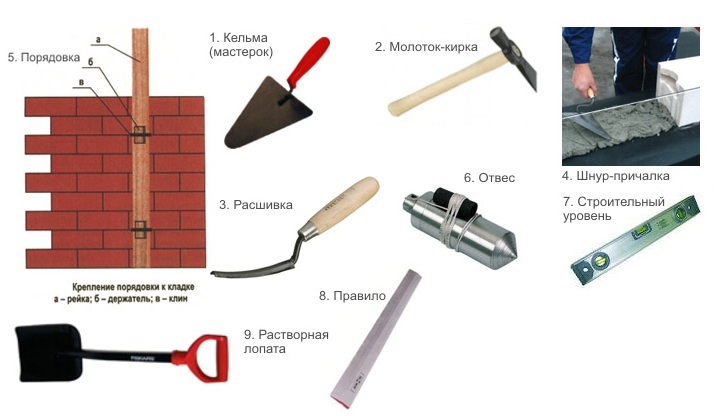

To complete the masonry you will need the following tools and materials:

- brick;

- building level;

- staples, hooks, crutches or other devices for fastening various architectural parts;

- plumb lines;

- cement mortar;

- solution container;

- rail;

- cord;

- rule;

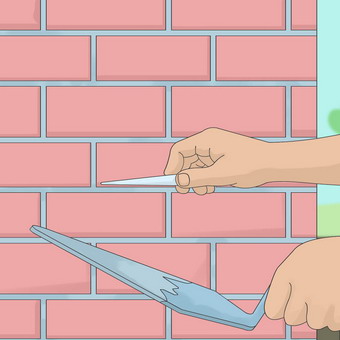

- jointing;

- trowel.

Return to contents

Types of decorative masonry

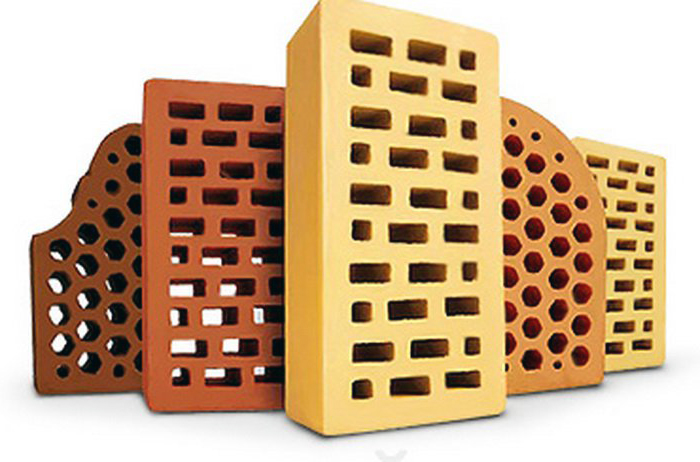

Despite the fact that such design takes longer and is more labor-intensive, the result is completely worth it. Today, the range of this material offers anyone a huge choice. Cladding from decorative brick allows you to lay figured window sills, bevels and elegant arches.

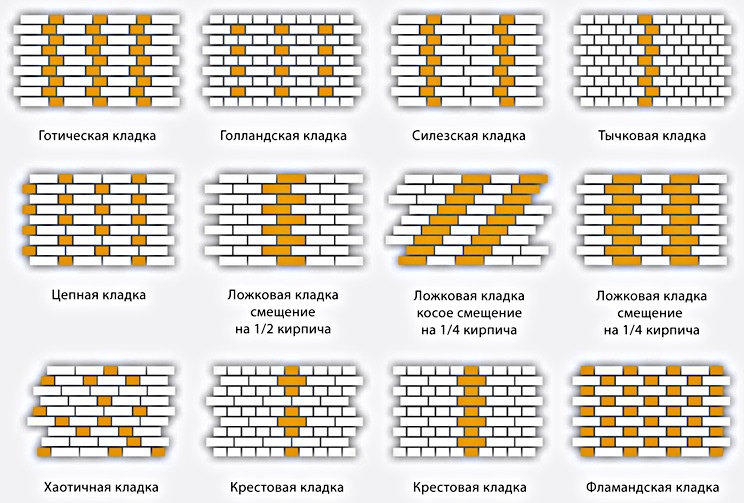

In most cases, the most popular masonry options are Gothic and Cross. When choosing the first of them, one row of spoons and one row of joints alternates, while with the second, two spoon bricks are laid with one brick. In addition to the original layout, after which a certain geometric pattern is formed, brick laying of different shades is often used in the cladding. When choosing, it is very important to pay attention to the fact that it has smooth edges. Sometimes a difference in shade can spoil the appearance.

Return to contents

Features of masonry

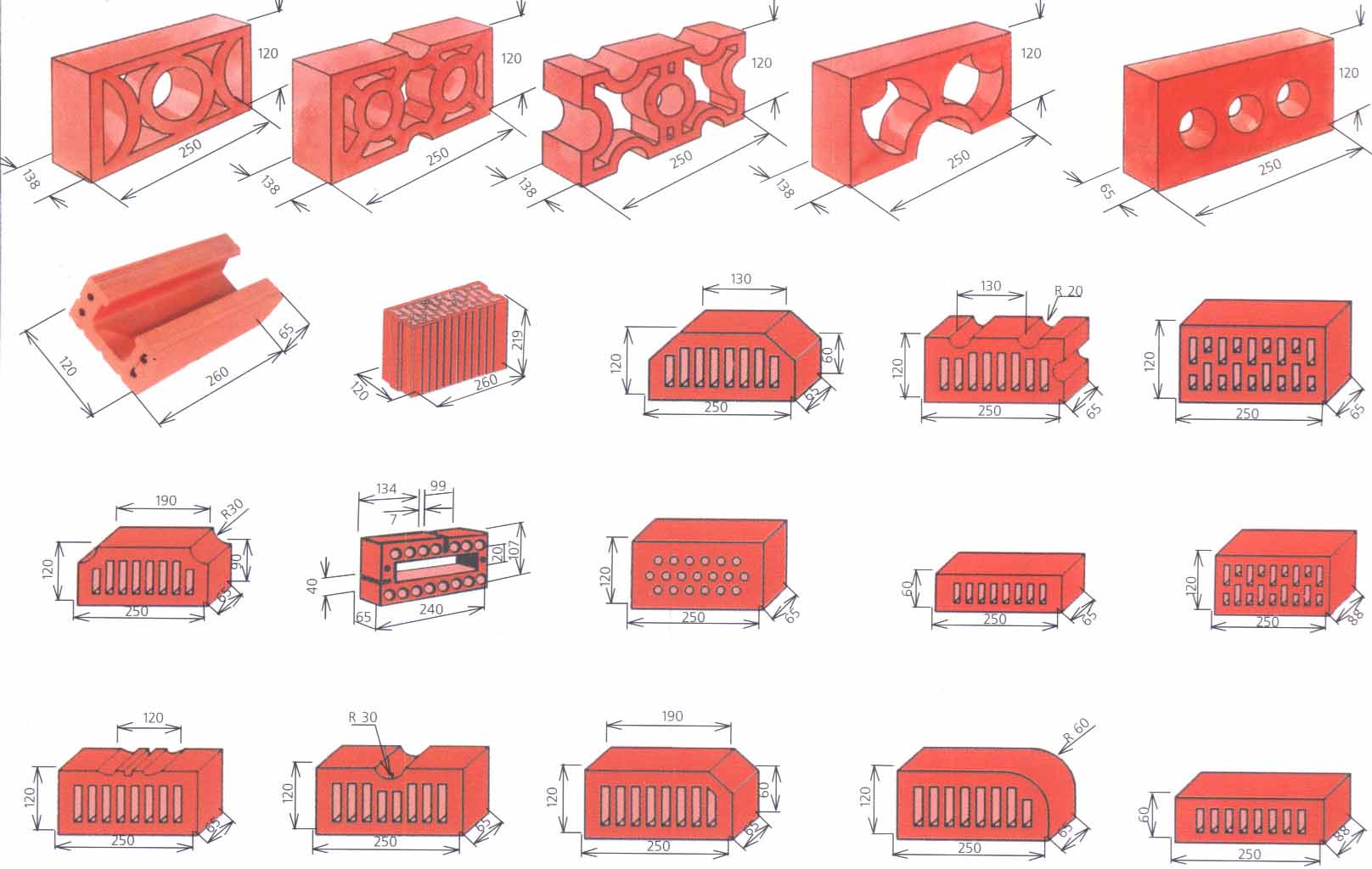

Using figured bricks you can design complex architectural elements: arches, bevels, slopes, pilasters.

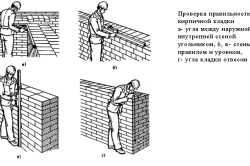

When using bricks for decorative masonry, it is very important to follow the rules for the bottom row. This work requires constant monitoring of clear horizontal and vertical lines. This can be done using a building level. It is important to maintain a uniform thickness of the seams.

If the wall is two bricks thick, then in the first outer row it is necessary to alternate spoon and butt types of decorative bricks.

When laying out the inner row, they use bonded ones, and when laying backfills, they use spoon ones. When filling the second row, the layout of the first is repeated, but with the use of ligating the façade seams vertically. After this, the inner mile is laid according to the principle of laying the outer one, but with backfilling made of interlocking bricks.

If, with the same thickness of the brick wall, cross decorative masonry is installed, then in the outer row you need to alternate one stick with two spoon bricks. All the pokes are located on the inner verst, and all the spoons are located on the back.

When performing the second outer row, the layout of the first is repeated. The only difference is to place the vertical seam exactly in the middle of the spoons of the bottom poke. The back row is erected with butts, and the inner row is built according to the principle of the outer one.

Decorative wall masonry often involves the presence of a variety of ornaments, which are easy to create using different colors of bricks and a pre-thought-out composition. This design option will not only make the building durable and attractive, but will also give it individuality.

Pilasters are usually made of sand-lime brick, the area located under the window, as well as the frame for windows and doors, is made of brick in contrasting shades (for example, red). A template is used to lay out figures of different objects, animals or plants. Such details can be used to frame and place accents around platbands, as well as belts and sandals.

The last one is considered to be a cornice extending beyond the surface, framed by a rectilinear or curved pediment. Sandrik is usually performed over a window or door.

Return to contents

Rusts, protruding parts and fastening

Another frequently used detail is rustication. They are horizontal grooves, which are located every 4-8 rows of brick and go to a depth of 0.6 cm. Rusts divide the facade, giving its surface relief.

Decorative masonry of belts and wall fragments: a - a belt made of bricks placed at an angle, b - the same, made of bricks installed at an angle and on an edge, c - wall detail made of bricks placed at an angle.

Masonry for making projecting rows is easily done using solid bricks. In this case, dressing does not matter here. A mandatory condition is not to exceed the overhang of such rows by more than a third of the length of the brick and the extension of the cornice without reinforcement by half the thickness of the wall. If the overhang is exactly half, it is necessary to make the cornice from reinforced masonry, which can be easily recreated using mortar (preferably grade 25) or using reinforced concrete.

A separate point that should be considered in this process is the fastening of various architectural details. There are several ways:

- using hooks;

- using crutches, which are usually embedded in sockets;

- using staples that need to be sealed into the seams of the masonry itself during its creation.

If working drawings are available, such fastening must be performed using those devices that are directly indicated in them.

This method is used not only for cladding the facade walls of various buildings; brick fences, gazebos and barbecues, and decorative architectural elements are also erected in this way. What is “Bavarian bricklaying”?

Features and brief technological characteristics of Bavarian bricklaying

First, you need to clarify that this is not some unknown German masonry, but a special type of brick. As for the actual masonry, the Germans did not come up with anything original; everything is done according to the usual and long-known technology. The name appeared in connection with appearance brick walls caused by brick parameters. By the way, the walls of all ancient buildings have this appearance, not only in Germany, but also in other European countries, including Russia.

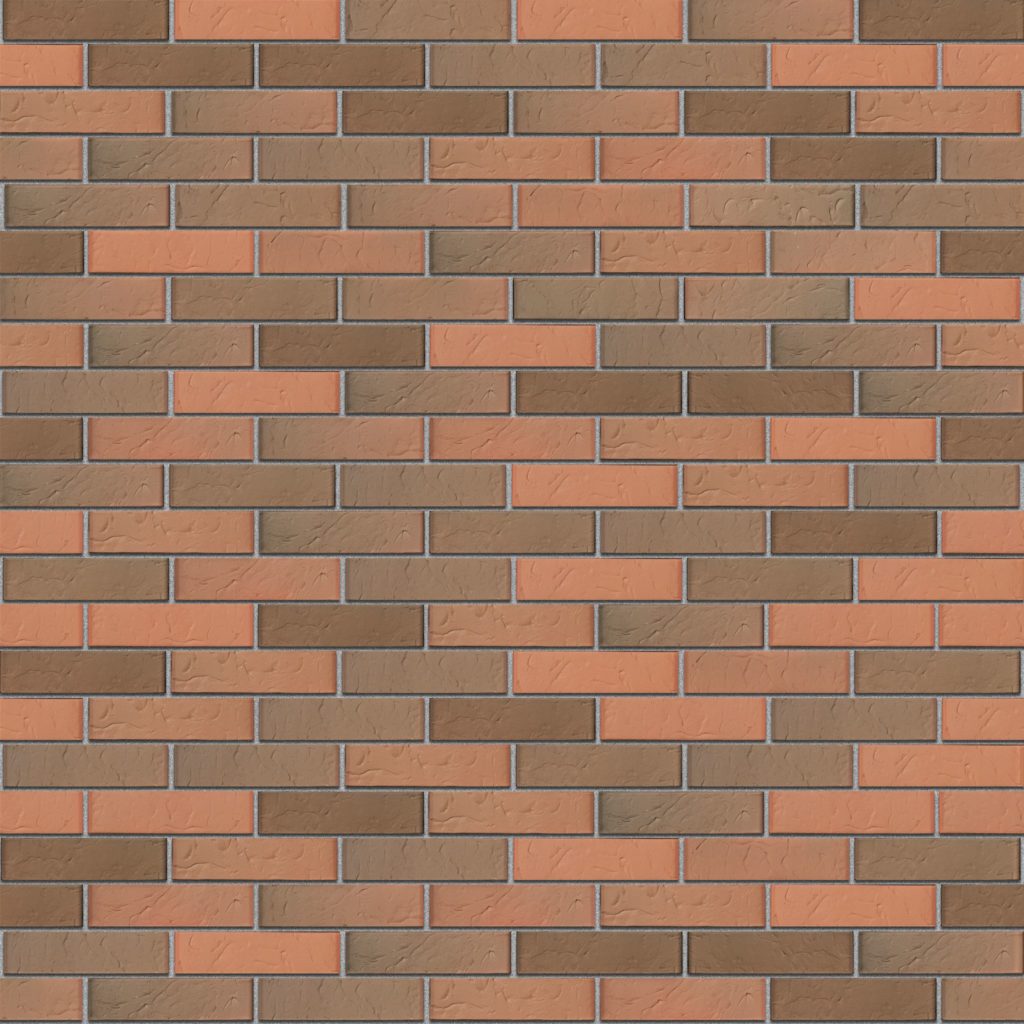

The front side of the houses is not monochromatic, but has different shades that form unpredictable patterns. Previously, no one specifically tried to build houses with “multi-colored” facades; on the contrary, they tried to achieve a uniform color. But the imperfection of brick production technology did not make it possible to obtain material with absolutely identical properties; depending on the method of preparing the mixture, the chemical composition of the clay, temperature conditions and firing time, each batch unloaded from the kiln turned out to be of a different shade.

Prestigious buildings were plastered, and industrial buildings and the houses of poor residents had a motley appearance. Nowadays modern technologies allow the production of bricks of the same appearance, the mixing is precisely controlled and chemical composition clay, a constant annealing temperature makes it possible to obtain bricks that are absolutely identical in physical characteristics and appearance. But the country (rustic) style came into fashion, and colorful façade walls became not a disadvantage, but a design solution. Manufacturers had to develop special firing technologies to produce Bavarian brick, a material with different shades of the front surface. Complex technology, of course, has caused an increase in production costs, which explains the high price of bricks.

How is Bavarian brick made?

It is produced using the flash firing method.

On final stage Air is additionally pumped into the furnace, oxygen increases the heating temperature of the upper layer, and becomes a catalyst for removing certain chemical compounds from the clay. As a result, the surface changes color. The color range of products changes as planned; precise control of modes makes it possible to obtain predictable shades. In addition, due to the high temperature, the outer layer is sintered to a glassy state, the brick becomes much stronger, does not absorb moisture, does not change its original properties throughout the entire period of operation, and it reaches several hundred years.

The thickness of the glassy layer is also adjustable and, depending on the specific brand, ranges from 2–4 mm. Another advantage of Bavarian brick is that efflorescence does not appear on the surface; this phenomenon is excluded even theoretically. The fact is that during a short-term increase in firing temperatures, the salts have time to decompose. In addition, the glassy front surface does not allow the release of salts, it is almost airtight.

Facing brick “Flash firing” – Bavarian masonry

The most technologically advanced enterprises have learned to achieve not only a uniform color on the surface, but also multi-colored streaks of bizarre shapes. Such bricks are used only on the most critical buildings and structures. External surfaces can be smooth or textured.

Facing brick BRAER “Bavarian masonry” oak bark with sand

![]()

We have figured out the peculiarities of the technology for making Bavarian brick, now we can consider recommendations for its laying.

Preparatory activities

Before you give step by step instructions masonry, consider several features of Bavarian masonry.

Bavarian masonry can be used as separate cladding or as the outer row of a brick wall. During separate cladding, you can use foam boards to insulate the wall. But we do not recommend using this method of insulation; its actual effectiveness is far from expected. The fact is that freely lying in the space between load-bearing wall and cladding, foam plastic boards do not interfere with the thermal convention of air, which is what leads to the main heat losses.

To eliminate convection, you need to additionally tightly fill the space between the foam and the walls with liquid foam. This significantly increases the cost of construction work.

There is another method of insulating facade walls for cladding with slabs - plaster the wall, glue or fix the slabs with dowels, seal the gaps between them and only then begin cladding with Bavarian bricks. But this method also increases financial losses significantly. From an economic point of view, it is better to insulate such walls from the inside of the premises.

Step-by-step instructions for the work

Use bavarian brick it is possible both for separate cladding and for the external visible row of load-bearing facade walls during their laying. The physical characteristics of the material make it possible to use it for the manufacture of loaded architectural elements.

For example, we will consider the option facing masonry Bavarian brick. Which method you choose, detailed comparative characteristics is on our website.

Step 1. Check the verticality of all façade walls. To do this, you will need a plumb line, check the position of the walls along the entire height, and mark the preliminary position of the cladding on the foundation. Please note that the minimum distance between the main wall and the cladding is no less than the thickness of the insulation. If there is no insulation, then choose the minimum distance; all cracks will be sealed with mortar.

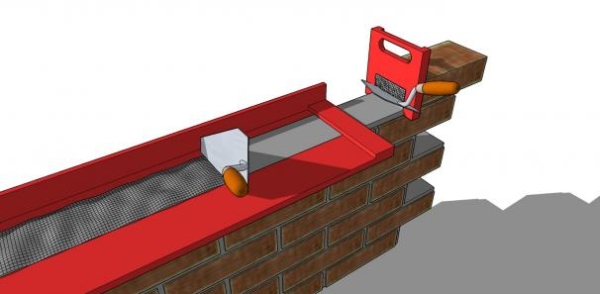

Step 2. Mark the position of the first row of bricks; it is very important that all the bricks on the cladding are intact. Lay out one row of Bavarian bricks, starting at one corner and working towards the opposite. The distance between them is within 8–10 mm. To control the width of the seam, prepare devices. You can buy them at a hardware store or make them yourself. We suggest doing it yourself; for this you will need a square profile with a side of 8–10 mm. One piece is approximately 50–60 cm, and is used to control horizontal seams. The second piece is 15–20 cm long for installing a vertical seam. When laying out the first row, use a metal rod.

If the layout does not end with a whole brick, then widen the gaps a little. Increase the distance between adjacent bricks by no more than 2–3 mm at a time, otherwise the discrepancy will become noticeable. After 20–25 bricks you can eliminate up to 10 cm in size, this is enough for most possible cases. Is it difficult to adjust the gap? You will have to cut off the brick; in the future, use it in inconspicuous places.

Step 3. Clear space near the wall from construction debris and unnecessary items. Take care of the scaffolding right away; they will be needed when the cladding height is 1.5-1.6 meters. You can make scaffolding yourself from lumber, borrow or rent ready-made metal ones. The second option is preferable: it is much safer to work, the speed of masonry is noticeably increased due to the efficiency of changing the height of the site depending on the number of facing rows.

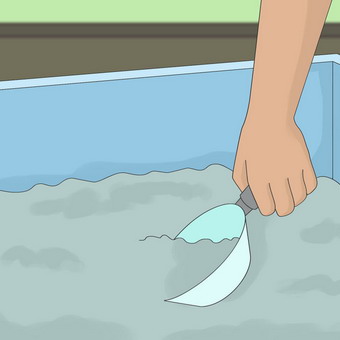

Step 4. Prepare masonry mortar at the rate of one part cement to four parts sand. Water is added as needed. The mortar should be somewhat thicker than for masonry with ordinary red brick. The fact is that Bavarian absorbs less moisture and can “float” when using a liquid mixture.

Step 5. Place waterproofing on the foundation; for this purpose it is better to use two layers of roofing material. The laying begins from two opposite corners, raise them to a height of 4–5 rows. Constantly monitor the position of the corners with a plumb line or level. Remember that the most accurate tool for checking verticality is an ordinary plumb line or level, which has permissible errors, which can accumulate over time and create problems. Each corner should have a width of 4–5 bricks at the base, then its width is reduced by half a brick. While you are working on the corners, do not remove the installation row. It will gradually be removed during further laying. High-quality Bavarian brick has high levels of dimensional accuracy and parallelism of surfaces, which simplifies the work. We will tell you below what to do with low-quality material.

Step 6. Stretch the rope between the corners and check that it is horizontal.

Pull the threads to control the evenness of the masonry

Everything is in order - start laying one brick at a time. Take it from the previously laid out row and place it on the solution. Adjust the width of the seams using metal square rods. Immediately remove any solution that gets on the front side of the cladding with a damp cloth. Move the twig along the rows as they increase. Remember to use different shades of Bavarian brick according to the previously developed plan. There is no need to count them, the main thing is that the approximate ratio of the different colors is observed. Do not forget that the main background should occupy at least 50% of the area of the facades. If you want, you can roughly follow the alternation of colors, make a mistake - no problem. Bavarian masonry does not have symmetrical patterns.

Practical advice. Facades decorated with colored bricks only in window and door openings, corners, arches, etc. look very original. And for other surfaces you can use ordinary facing bricks. But this is a matter of taste, make your own decisions.

Step 7 After 4-5 rows, start grouting the masonry joints. The number of rows depends on your skill and professionalism; change it to suit your individual capabilities. The main criterion for starting grouting is that the mass should harden a little, but not harden completely. Grouting is done with purchased plastic devices, homemade metal or wooden ones. The width of the devices should allow working in seams without jamming. If gaps in the mortar are found during grouting, add it and re-level it. Constantly clean surfaces of dirt, do not leave work for later. If cement mortar remains on the surface of Bavarian cladding for a long time, it can cause stains that are difficult to remove; it is much more effective to do all the work in a timely manner.

Step 8 Carefully place the cladding in the openings. In most cases, the brick will have to be cut to length. Use a cylindrical grinder with a diamond disc for this. The cut brick should not be placed at the corner of the opening; place it a few bricks earlier.

Step 9 To increase the stability of the cladding, tie it to a load-bearing wall. For these purposes, periodic profile construction reinforcement, metal mesh or perforated galvanized strip are used.

It is easiest to work with a perforated strip: it has decent strength indicators, its position can be easily adjusted taking into account the height of the row of cladding, and fixation to the load-bearing wall can be done with ordinary dowels. Practitioners recommend making fastenings at a distance of 2–2.5 m horizontally and 1–1.5 m vertically. There are craftsmen who do not use anchors; they assure that the cladding, even without it, has sufficient stability due to the common angles. This is correct, but for peace of mind it would not hurt to additionally tie the structures to each other. Moreover, it takes little time.

How to fix a strip?

Further work continues according to the above algorithm. Do not forget to constantly alternate the colors of the Bavarian masonry. The scaffolding platforms are raised as needed; place bricks of different shades on them in several places.

Step 10 If there is Bavarian brick all over the cladding, continue laying as usual. If you want to use it only in some places of the facade wall, then proceed according to the previously drawn up sketch.

The depth of jointing has its own characteristics. Deep jointing perfectly hides existing unevenness and minor flaws in the shadow. Do it for ordinary mass. But in Bavarian masonry, white jointing is often used; it gives the façade of buildings an exclusive look. The shadow for white paneling is not a helper, but an enemy; it smooths out the contrast of the facade design. Keep this in mind, white jointing cannot be made deep, maximum 1–2 mm. This automatically means that the seams must be perfectly even and without gaps; the slightest problems are visible on a white background.

Correct and incorrect types of seams

There are cases when developers, due to inexperience or in order to save money, buy low-quality bricks. The best option is to take several bricks before purchasing, lean them one by one against each other with all their edges and check the gaps and variation in size. But if low-quality material has already been purchased, then you will have to learn to work with it. This needs to be laid using a slightly modified technology.

![]()

If you strictly follow the Bavarian masonry technology, the facade will not only be beautiful, but also durable. Never rush to do the work, remember that correcting mistakes in any case takes more time than careful masonry. It is impossible to describe all possible cases in one article; learn to make independent decisions; the more practical experience you have, the easier it is to solve the difficulties that arise.

Video - Bavarian bricklaying

Natural brickwork and materials imitating it, features of use in premises for various purposes.

Contents of the article:

Brickwork in the interior is an interesting design solution that can give any room a bright personality and turn it into a real masterpiece. When used skillfully, rough material intended for the construction of walls can create a cozy atmosphere in a home, bringing into it a spirit of mystery and even a certain audacity. Arsenal good designer is always full of a large number of different techniques with the help of which ordinary brickwork can become part of the philosophy of the surrounding space.

Natural masonry in the interior

If in new brick house finishing has not yet been carried out, one of the walls of the room can be left in natural form to create a decorative element of the future interior. To emphasize the individuality and sophistication of the masonry, you will have to work hard.

To begin with, the surface of the brick wall must be thoroughly cleaned of construction dust and frozen mortar splashes, treated with various antiseptics and primers, and then varnished or painted. Thanks to the natural texture of the masonry brick, many interesting design solutions can be implemented using its external decoration.

A brick wall can have a rich range of colors, a matte or glazed surface, an aging effect, or a perfectly flat plane. All this is achieved by using modern finishing materials, in a huge variety presented by their manufacturers on the construction market.

However, it is important to know that clay or silicate brick is primarily a product intended for laying walls, and is not initially intended for certain types of direct processing. Therefore, painted masonry requires periodic surface renewal to maintain its aesthetic appearance. Tile pigments of various shades are used to fill the joints between bricks.

Below are tips to help you paint correctly. brickwork in the interior:

- It is not recommended to paint fresh masonry. The wall material must be completely dry, otherwise moisture coming from the pores of the brick can deform the applied coating.

- Salt deposits on bricks should be removed with a stiff brush and water; it is not recommended to use acidic solutions for this.

- To prime the masonry before painting, you need to choose a composition that will be resistant to alkali.

- Natural masonry can be made from facing bricks. Then the process of painting it will be significantly simplified.

How to design decorative masonry in the interior

It happens that, due to the lack of walls in the room suitable for such decoration, brickwork has to be imitated with various materials. For this purpose, wallpaper, special tiles, artificial stone, plastic panels and airbrush coatings.

Wallpaper with a pattern

On the one hand, the use of this material may seem like an outdated finishing method left over from the last century, but on the other hand, “brick” wallpaper can become indispensable for budget renovations for decorating, for example, a small niche, and sometimes the entire wall.

Wallpaper that imitates the texture of brickwork can be made “for painting” or have a full-fledged printer print. Of course, this option for decorating a room is unlikely to have the effect that can be expected from natural brickwork, but it will certainly attract attention and become an accent of the interior. By wisely selecting other details to match it, you can create a unified style for the space of the room.

Brick look tiles

Wall cladding with such tiles is the most popular way to imitate decorative brickwork in the interior. In addition to the similarity of the surface of the material with the texture of natural brick, the tiles have high strength, aesthetic appearance, chemical resistance and ease of maintenance. It is resistant to temperature fluctuations, environmentally friendly and hygienic. These advantages make tiles an ideal finishing material for walls.

To install it, a special glue is required, sold in the form of a dry mixture. After adding water to it, a ready-made solution is obtained, which is applied to the back of the tile and the wall with a notched trowel in an even layer. The joints between the tiles should be no more than 12 mm wide. They are filled with special colored grouts or ordinary mortar for jointing. The edges of the cladding are decorated with decorative corners.

Artificial stone

No less high quality than tiles is artificial stone “brick-like”. The rules for its installation do not differ from the above method, however, this material looks unique and original in its own way. It is indistinguishable from natural brick, but artificial stone is much thinner, lighter and easier to process.

It goes well with wood and plastic, has low thermal conductivity, high strength and durability. Decorative stone is non-toxic and resistant to temperature fluctuations. You can buy it or mold it yourself in the form of tiles from a putty mixture or gypsum, and then glue it to the wall.

Plastic panels

The effect of brickwork can be created using PVC panels. This is a modern material that combines not only imitating properties and aesthetic beauty, but also environmental safety, moisture resistance, high strength and affordable cost.

Installation of plastic panels does not require careful preparation of walls, special equipment or special professional skills. The products are easily installed using special glue or fastening clamps.

Airbrush

The implementation of some solutions to create the intended interior is not always possible solely using the above-mentioned materials. Sometimes on the wall you want to see not only the texture of the brickwork, but also other details. For example, doors, windows or part of the roof.

This effect can be achieved using airbrushing. Using this method, any drawing can be created, starting with an image of a brick wall entwined with grapes, and ending with a picture of the entire facade with a balcony, doors and windows.

The drawings look quite realistic and can be applied to walls made of various materials. To obtain additional effects, fluorescent and luminescent paints are often used, which provide image play depending on the lighting and time of day. For example, good decision will add night reflections of lanterns or luminous windows to the pattern of brickwork.

Brickwork in the interiors of different rooms

When using natural or decorative brickwork, the interior design looks unusual and bold, serving as a reminder of antiquity, creating a positive mood and cozy atmosphere in the room. A successful choice of colors and decor of the seams of a brick wall is of great importance. Any room in a house or apartment has a specific function, so they are decorated with brickwork in different ways.

Brickwork in the hallway

Brick in the interior of hallways is difficult to install due to the presence of storage rooms and the small area of such rooms. As a last resort, you can lay one of the walls with bricks.

Another material for decorating a hallway can be tiles that imitate brick. It has a small thickness, which is an important point when maintaining the usable area of a small room. The adhesive for tiles should be a high-quality polyurethane-based one.

This is especially important in a hallway, since a constantly slamming entrance door causes vibration in the walls, which can lead to the collapse of poorly glued tiles.

The simplest option is to stick wallpaper, the pattern of which will imitate the texture and appearance of brickwork in the interior of the hallway.

Brickwork in the living room

In the living room interior, a brick wall is an excellent basis for design in any style. Fans of minimalism can decorate the room with simple furniture, avoiding unnecessary decorative elements. Connoisseurs of ethno-style interiors can decorate the room with decorative vases, photographs, carpets or various handicrafts made with their own hands.

Brickwork goes perfectly with a classic interior, harmonizes well with crystal chandeliers, decorative accessories and antique furniture. When decorating a living room, it is important to include imagination, not limiting yourself to desires.

As an alternative to natural brick, you can use decorative tiles and paper wallpaper. You should not try to finish all the walls of the room with brick. If you overdo it, it can look like a warehouse or cellar. A good solution would be to decorate a section of the wall near the fireplace or one entire wall with brickwork.

A sign of the grace and perfection of a huge living room can be brick columns made in the Greek style. They can be used to divide a room into zones or as exclusive decor.

Beautifully decorated brickwork in the interior of the living room will emphasize the refined artistic taste of the owners and set up his guests for a warm, confidential conversation.

Brickwork in the bedroom

In the interior of the bedroom, brickwork is quite attractive, while its material does not conflict with the soft tones and texture of textiles. Optimal use of this design does not in any way affect the illumination of the room.

If the bedroom already has a finished brick wall, it can be tidied up and coated with clear varnish. Another option is to paint it a bright color, this design is good for bedrooms decorated in an eclectic or Scandinavian style.

Being in the bedroom, a person is inclined towards comfort and relaxation. Therefore, the walls of such a room are often decorated in soft, calm and restrained pastel colors.

Brickwork in the kitchen

Imitation brickwork made from special tiles looks great in the kitchen. The red cladding resembles country style in appearance, and the brick wall, painted in white, somewhat softens the interior design, allowing its use in the Scandinavian style of kitchen design.

Inexpensive and high-quality finishing of a kitchen in the loft style can be done using facing stone in the form of thin tiles. The wall must be perfectly flat. Tile adhesive and joint grout are used for work. You can use brick-like tiles to decorate a kitchen backsplash, and select appropriate materials for decorating other walls.

With the help of brickwork in the kitchen interior it is possible to create a romantic atmosphere. This design favorably emphasizes the solidity and luxury of the room. In large dining rooms, you can decorate one or more walls at your discretion. This brickwork goes well with wood, metal and glass. Interesting solutions can be obtained by combining kitchen appliances with a background of brick walls.

Decorative brick finishing is often used in the kitchen when decorating its dining area. A similar effect can be achieved if you lay out a brick partition separating the dining room and living room. To create the effect of spatial zoning, brick finishing is performed only in one of the rooms.

Advice! Despite the fact that brick has several standard shades and is suitable for any interior, it would be better to play it safe and pay attention to the color scheme of the room and the features of its design.

Brickwork in the bathroom

In the bathroom - special conditions stay. Large temperature changes periodically occur here, and high air humidity is observed. Therefore, its design with masonry requires the use of special ceramic tiles or natural clay bricks, the roughness of which will create an unusual contrast in combination with white faience sanitary ware.

Bathroom walls decorated with smooth tiles also look good. It gives the interior a feeling of cleanliness and freshness. In addition, unlike brick cladding, tiled covering saves precious square meters, which is especially important for small rooms.

If the size of the bathroom allows, you can line one of its walls with brick. It will emphasize the style and individuality of the room. Before this, you should estimate the cost of the material and familiarize yourself with the photo of brickwork in the bathroom interior already finished projects presented on Internet sites. A successful experiment could be combining masonry with a glass partition between the bathtub and toilet or washbasin and toilet.

If you don’t want to tinker with brick or tile, you can imitate masonry with vinyl moisture-resistant wallpaper that has the appropriate pattern. They are not so durable, but such a coating can always be easily replaced without much effort. At the same time, “brick” wallpaper often has such a natural appearance that it can only be distinguished from real cladding up close.

How to make brickwork - watch the video:

A building material that has been in use for over 100 years is now almost a work of art. The use of brickwork in the interior has a special charm and will certainly not go unnoticed. However, for various reasons, such as repair time, cost of projects and many others, the possibility of using high-quality brick imitation using ceramic granite or tiles with the appropriate texture is much more often determined. However, it's up to you to decide. Good luck!

The cladding of a house is an important condition on which further wear and tear of the entire structure depends. For this reason, it is important that it is durable, strong, and most importantly, of high quality. Therefore, many builders believe that it is the laying of a brick facade that allows one to preserve the original appearance of the structure for a long time, and also extends the wear and tear of the house for a long period. But before you start laying, it’s worth considering the types of materials that can be used for the facade.

Cladding the facade of a house with brick is a fairly reliable external coating that provides not only high protection, but also gives a rich appearance to the structure. In addition, brick cladding has a number of advantages:

- brick finishing has clear, concise geometric shapes and sizes;

- the lining has a breathable structure. Due to the fact that brick walls are porous, they remove moisture, so dampness never occurs inside the house;

- brick material has increased resistance to sunlight. This property is ensured due to the presence of non-fading dyes and elements in ceramic products;

- brickwork does not need to be additionally treated with special solutions against exposure to aggressive atmospheric precipitation;

- the brick base withstands sudden changes in temperature both indoors and outdoors;

- long wear - a facade made of brick material has a long service life, it can easily stand from 50 to 100 years. But it is worth remembering that its service life directly depends on the type of brick, the method of laying it and compliance with the entire procedure when installing a brick facade;

- withstands wind influences;

- have a reduced level of stress and deformation. For this reason, cracks and various damage rarely occur on facades;

- acceptable level of heat resistance - brick products withstand the effects of fire;

- The brick base has a low level of moisture absorption - from 6 to 30%. Therefore, houses with a facade made of this material will be able to withstand increased levels of moisture;

- if suddenly the need arises to repair a certain area, you can easily replace it with new brick;

- the material is highly environmentally friendly. It does not emit toxic substances and therefore has no harmful effects on human health;

- from a brick base you can make various architectural and design solutions - arches, niches, curved niches, complex structures;

- easy care - in order to wash away dirt and dust from the surface of a brick facade, just rinse it with water from a hose.

But in addition to advantages, there are also negative qualities, but there are much fewer of them, unlike positive aspects. The disadvantages include the following characteristics:

- it is necessary to equip a reinforced foundation;

- Difficulties may arise during laying;

- high cost of the work carried out;

- ordinary brick cladding has low thermal insulation qualities.

Types of bricks

The brick facade of buildings can be made of different types material. The main requirement is that the cladding be durable. Therefore, when choosing a material, you should first carefully familiarize yourself with its types and properties.

The following material can be used for cladding the external walls of buildings:

- silicate type;

- clinker type;

- hyper-pressed type;

- ceramic type.

Hyper-pressed

Hyper-pressed  Clinker

Clinker  Silicate

Silicate Silicate

This type of brick is considered a simple and budget-friendly construction option for cladding buildings. But, despite this, it has a number of advantages:

- this material has high thermal insulation;

- provides high protection of external walls from deformations, cracks, and various damages;

- is an excellent barrier against the effects of moisture and precipitation;

- withstands sudden changes in temperature;

- installation of this material is simple, so even a beginner in this matter can handle it;

- prevalence- this material can be purchased at a hardware store.

Clinker

The properties of this material are similar to classic brick. It has low cost and is also suitable for façade cladding. In addition, it has a number of positive features:

- clinker brick has high strength;

- durability - this material has a service life of 50 to 100 years;

- has a unique composition - to make this material, clay with a certain structure is used, it is fired at a temperature of almost 1200 degrees Celsius. During this firing process, sintering of elements inside the brick structure is observed;

- Available in different textures;

- On sale you can find clinker-type bricks in various colors.

Hyper-pressed

This material is made from shell rock with the addition of crushed limestone. It is ideal for installation on external walls buildings.

Main features of this material:

- high strength - its degree is almost 150-300 kg/cm2;

- has a low level of water absorption, almost 6%. This property prevents the occurrence of dampness, fungal and mold infections inside the house;

- has an increased class of frost resistance, so it does not collapse under the influence of severe frosts in the cold season

- a variety of designs and sizes provide the opportunity to create facades with a unique style;

- various color schemes that will give the external walls an unusual, bright appearance.

Ceramic

Ceramic brick is an excellent basis for decorating the external walls of buildings, buildings, and residential buildings. In its composition, quality, and strength, it is not inferior to other types of brick material. In addition, it is worth highlighting the main positive characteristics of this type of brick:

- ceramic bricks can have a full or, conversely, hollow structure;

- Regardless of the structure, the material has high level water absorption, so there is no dampness, fungal infection, or mold in the room;

- excellent resistance to exposure to sunlight;

- has a high level of fire resistance - does not ignite when exposed to an open flame;

- has a unique composition - the highest grade clay is used to produce this brick, so the base of the cladding looks original, beautiful and stylish;

- may have a different surface structure - glazed (smooth) and matte.

Since ceramic brick has only a few colors, it is available in red, brown, and orange colors. Therefore, when choosing a brick, you should take this quality into account.

Types of brickwork

Facade brick is a fairly durable material with high quality, unique texture, and beautiful appearance. But still, the final result of a brick facade depends on how the main material is installed. It is worth remembering that the duration of wear and tear of the entire structure, as well as its appearance, will depend on literacy and responsibility for performing all work.

Facade bricks can be installed in several ways; it is worth highlighting the most original methods:

- track - during installation in this way, all layers have only long sides. When installing the sides will mix a few cm in each row;

- block type - this type of masonry has the property of constantly alternating short and long sides of the brick material, in which the joints are installed in a vertical position;

- crosspiece - with this method of masonry, brick material with long and short sides alternates in the same way as when installing a block type. But on each side of the second row it is necessary to shift half a brick; thanks to this installation method, the result is a cross pattern;

- Gothic type masonry - with this installation method, there is an alternation of short and long sides of the brick. As a result, it turns out that in the second rows the joints are located one above the other, and in the first rows the brick material is shifted halfway on the short side;

- decorative masonry - this masonry involves not only installing bricks in the form of various patterns, but also their variety with multi-colored materials.

Types of facing bricks

Types of facing bricks When choosing a certain masonry method, it is worth considering that the installation technology may not always be feasible, especially if you are still new to this matter. It is best to entrust the installation of bricks for the facade to professionals, because he is the one who will be able to do it correctly.

Dimensions, markings and material texture

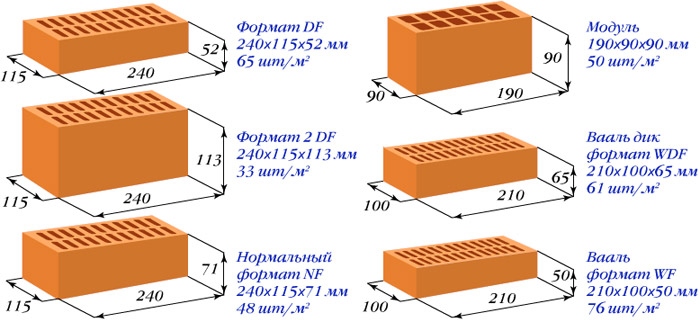

Before you begin installing a brick facade, it is worth finding out the size range, markings and structure. The table below shows the approximate dimensions of the brick material.

|

Name |

Size range markings | Size range |

| Single type brick | 1 SF | 250x120x65 |

| Euro | 0.7 NF | 250x85x65 |

| Modular single type | 1.3 NF | 288x138x65 |

| One and a half brick | 1.4 NF | 250x120x88 |

| With horizontal voids | 14 NF | 250x120x88 |

| Double type brick | 2.1 NF | 252x122x142 |

| Large-format stone with ceramic porous structure | 14.3 NF |

Dimensions of facing bricks

Dimensions of facing bricks  Forms of facade bricks

Forms of facade bricks Styling solutions

In order for the cladding of a house to last for a long time, protect external walls from various negative consequences, prevent their destruction and act as an excellent partition from precipitation, it is necessary to choose a high-quality mixture for installing bricks.

Solutions for installing a brick facade are of the following types:

- cement - this solution is prepared from dry sand and cement powder. The proportions of these components can be different, it all depends on the quality of the cement. Typically, there are three to six parts sand to one part cement. This solution is suitable for installing any brick and ensures strong attachment to the base;

- lime - these mortars have an increased level of plasticity, but they are not as strong as cement ones. They should be used for the construction of interior walls and doors. The solution contains lime paste, sand and quicklime powder;

- cement-lime mortar - this mixture includes lime paste and cement. The finished solution has high plasticity and strength. It can be used for fastening almost all types of bricks.

Lime

Lime  Cement-lime

Cement-lime  Cement

Cement

Once the material for the facade has been selected, you can begin the installation itself and the formation of the facade. The first step is to prepare well for the work process. It is imperative to prepare the necessary equipment, which must include the following tools:

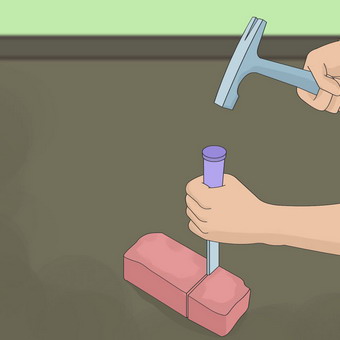

- a tool for hewing and chopping bricks - a hammer;

- a tool used for scooping up the solution, as well as for leveling - a trowel or spatula;

- jointing device - it is used to give the seam a certain profile;

- plumb line - this device is necessary to check the vertical level of the wall surface. Its weight should be between 200-600 grams;

- order of wooden material. It is used for fixing and marking rows of masonry;

- chalk type cord - this device is used for guidance. It helps to mark straight lines, horizontal rows when laying;

- tape measure for taking the necessary measurements;

- buckets;

- shovels;

- concrete mixer or container for diluting mortar for laying bricks.

Brickwork Tools

Brickwork Tools How to lay bricks correctly

The technology of all work begins with preparatory stage. The first step is to bring in the necessary masonry material. The next step will be preparing the mortar for masonry. If you plan to carry out small volumes, then the solution can be made immediately. If a lot of work is planned, then it can be done in several passes.

It’s good if you have a concrete mixer, it will make the whole work process easier.

Using a concrete mixer

Using a concrete mixer The cladding technology is carried out according to the following scheme:

- First of all, the surface of the walls is prepared. It should be cleaned; if there are cracks or chips on it, then they are repaired;

- There must be a gap of 25-35 mm between the wall and the cladding. Any thermal insulation material can be placed in this place;

- It is desirable that there are air vents. They should be located below and above the brickwork. These places provide constant air circulation;

The presence of vents in the facade cladding is necessary for free penetration of air behind the cladding

The presence of vents in the facade cladding is necessary for free penetration of air behind the cladding - In order for the masonry to be strong, it must be strengthened load-bearing walls. To do this, it is recommended to make flexible connections for facing bricks and aerated concrete. Flexible connections are made of metal wire and dowels, which are installed every 3-5 rows of masonry;

Flexible ties for brickwork

Flexible ties for brickwork - then the brick is installed on the previously prepared mortar. You can cover the walls using various masonry methods, you can make drawings and patterns;

- laying bricks starts from the corners of the walls;

- The facing of drawings should be done from the 6th row. In order for the laying to be straight, it is recommended to additionally tighten the thread.

Common mistakes

It is worth remembering that when laying a brick facade, errors may occur that should be corrected in time:

- deviations from the vertical or uneven seams. With this error, the wall may often bulge in the central part or it may move away from the vertical to the left or right. This defect can be eliminated by applying a thick layer of mortar, but it is better not to use this method for cladding. It is better to be careful in advance and try to prevent this defect from occurring;

- unequal seams - mortar joints of vertical and horizontal types must be the same - 10 mm. Deviations up or down are undesirable. Otherwise it will have a negative impact on general view the entire building;

- defective bricks - you should not install bricks with various defects, cracks, chips, or deformations. All these defects will negatively affect the overall appearance of the façade of the building;

- dirty masonry - when laying the cladding you need to be especially careful; accidentally falling mortar from the trowel onto the wall can dry out. It will be especially noticeable against a light background of the cladding.

The brick cladding of an old house collapsed due to excessive load on the foundation

The brick cladding of an old house collapsed due to excessive load on the foundation Laying bricks on the surface of the walls of a building is a rather complex process that only professionals can handle. But if you still want to do this work yourself, be sure to select the appropriate material and study its properties. The further wear and tear of the entire structure will depend on it. Don’t forget to purchase the necessary equipment; it will help you complete the entire process of laying wall cladding much faster.

Brickwork of walls is one of the most ancient methods of masonry. The first samples were discovered during excavations in the territory of modern Balochistan: in the village of Mehrgarh, buildings were made of stones similar to modern brick. After conducting an analysis, it turned out that our distant ancestors used the simplest technology for laying brick walls back in the Neolithic, after all, it was not for nothing that this era was called “new stone”.

Advantages and disadvantages of brick walls

The main advantage of brick walls is that they are highly durable. In addition, it is not susceptible to rotting and exposure to microorganisms. Brick walls allow the use of reinforced concrete floor slabs. This is necessary if you want to cover a large span between walls. The small size of the bricks allows them to be used to build walls of complex configurations and lay out decorative elements of the facade. With brickwork, the walls of the house have great thermal inertia - in summer they are cool in any heat, in winter they are warm.

Brick walls also have disadvantages: if the house has not been heated for a long time in winter, it will take several days to warm it up. If the building is used seasonally, after 25 years the walls will require serious repairs. Brick walls are very heavy and do not tolerate deformation, so they require strip foundation to the freezing depth. To ensure proper thermal insulation, brick walls must be thick (in the Moscow region - 51 cm). Consequently, in a house with a usable area of 50 m2 they will occupy 17 m2 - 1/3 of the area; for a house with an area of 200 m2 this ratio will be 1/6.

Technology and thickness of lightweight brick walls

Homogeneous walls are made of ordinary hollow or light building bricks.

In non-uniform, lightweight walls, part of the brickwork is replaced by the thickness of the wall with thermal insulation tiles and an air gap.

Walls are erected with a thickness of 1/2, 1.1 1/2, 2.2 1/2, 3 bricks or more, taking into account the thickness of the vertical joints equal to 10 mm. Accordingly, the thickness of the wall with brickwork is 120, 250, 380, 510, 640, 770 mm and more. The thickness of the horizontal joints is assumed to be 12 mm, then the height of 13 rows of masonry should be 1 m.

There are two types of brickwork on walls: two-row (chain) and six-row (spoon).

In a two-row masonry system, bonded rows alternate with spoon rows. Transverse seams in this system overlap by 1/4 brick, and longitudinal seams by 1/2 brick.

As can be seen in the photo, the six-row brickwork of the walls involves alternating five rows of trays with one row of studs:

|

|

|

|

|

|

|

|

|

In each spoon row, the transverse vertical seams are tied in half a brick, while the longitudinal vertical seams formed by the spoons are tied in stitched rows through five spoon rows. Masonry The six-row system is easier than the two-row system. To reduce the air permeability of the walls, the facing seams of the masonry are sealed with a special tool, giving the seams the shape of a roller, fillet or triangle. This method is called seaming.

In the conditions of an average climatic region, the brickwork of external walls is made with a thickness of 2 1/2 bricks. Hollow brick masonry allows you to reduce the thickness by 1/2 of the brick.

The disadvantage of ordinary solid brick, clay or silicate, is its high volumetric weight and, consequently, high thermal conductivity.

Walls 2 bricks thick, made of hollow bricks with 32 or 78 holes at volumetric weight 1800 kg/m3, have a total heat transfer resistance that meets the requirements of an average climatic region.

The side and top planes of the openings - lintels - have quarters, i.e. protrusions that close the gap between the masonry and the window frame from the outside.

Currently, the most common are prefabricated slab or bar reinforced concrete lintels. Jumpers are divided into 2 groups according to their load-bearing capacity. The first group includes load-bearing lintels that bear the load from their own weight, the masonry above them, interfloor ceilings and other elements of the building.

Prefabricated reinforced concrete non-load-bearing lintels are marked: for timber lintels - with the letter B, for slabs - with the letters Bp.

Bar lintels are produced in a width of 120 mm, a height of 65 mm and a length of 1.2; 1.6; 2.0 m, and height 140 mm with length 2.4; 2.6; 2.8; 3 m.

Non-load-bearing slab lintels are produced in heights of 220, 300 mm and widths of 120 and 250 mm with a length of 1.4 to 3.2 m.

Non-load-bearing lintels are laid into the walls on supports at least 125 mm, and load-bearing ones - 250 mm. When laying block lintels, one block at the outer surface of the wall is laid 75 mm lower than the others to form a quarter. The window block frame is adjacent to the latter.

Smoke and ventilation ducts are installed, as a rule, on brickwork of internal walls, since in the ducts located in external walls, draft is disrupted in winter due to the cooling of their walls. If it is impossible to do without installing channels in the outer walls, the wall is thickened so much that the distance from the inner surface of the channel to the outer surface of the wall is no less than the minimum thickness of the wall that meets the climatic conditions.

Smoke duct cross-section heating stoves and kitchen hearths take the size of 1/2 x 1 brick. Smoke ducts of small stoves, for example, bathroom columns, and ventilation ducts allow a cross-section of 1/2 x 1/2 brick.

The crowning cornice of a brick wall with a slight offset - up to 300 mm and no more than x/2 the thickness of the wall, can be laid out of brick by gradually releasing rows of masonry by 60-80 mm in each row. When the projection is more than 300 mm, the cornices are made of prefabricated reinforced concrete slabs embedded in the walls.

The inner ends of the reinforced concrete slabs are covered with prefabricated longitudinal reinforced concrete beams, which are attached to the masonry using steel anchors embedded in it, thereby ensuring the stability of the cornice.

Lightweight brick walls, in which the brick is partially freed from heat-insulating functions unusual for it by replacing part of the masonry with less heat-conducting materials, can significantly reduce brick consumption, thereby increasing material savings.

Lightweight brick walls are divided into 2 groups. The first group includes structures consisting of two thin longitudinal brick walls, between which thermal insulation material is laid, the second group includes structures consisting of one brick wall insulated with thermal insulation slabs.

Backfill walls consist of two walls 1/2 brick thick, the space between which is covered every 4 rows by two horizontal rows of solid masonry. These two rows divide the masonry heightwise into shallow cavities, which are filled with slag as the wall is built. The backfill gives almost no precipitation.

When laying lightweight brick walls, they are given strength by continuous horizontal rows, but their thermal properties are impaired, creating areas with high thermal conductivity. Backfill walls are installed when the height of the house is no more than two floors.

Walls filled with lightweight concrete differ from walls filled with slag in that the space between the enclosing walls of 1/2 brick is filled with lightweight concrete. For walls with filling, every 3-5 tray rows, lay out one butted row of bricks embedded in the concrete.

In this case, the butt rows are placed in one row, in walls 510 mm thick and thicker, or in a checkerboard pattern, in walls 380 mm thick. Minimum thickness of such walls is 380 mm, maximum - 650 mm.

In internal walls, the diaphragm is formed by overlapping interlocking rows on the mortar. The voids of the internal walls are filled with light or ordinary concrete, and also filled with broken bricks and filled with mortar, i.e. doing backfilling.

The advantage of brick-concrete walls compared to backfill walls is that the adhesion of concrete to masonry provides a more reliable connection between the brick walls and, in addition, the concrete absorbs part of the load transmitted to the wall. Brick and concrete walls are erected during the construction of a house with a height of up to 6 floors.

When carrying out work in winter, the labor intensity of the work increases, since the drying of the masonry slows down the introduction of a large amount of moisture into the wall with the concrete mixture.

Watch the video of brick wall laying to better understand the technology of the process:

Construction of brick walls with insulation and thermal liners

The structure of a brick wall with insulation from heat-insulating panels consists of a load-bearing part - masonry, the thickness of which is determined only from the conditions of the strength and stability of the wall, and a heat-insulating part - foam concrete, gypsum or gypsum slag panels.

![]()

In the plane of the interfloor floors, panels 4 are supported on the floor structures. The panels are attached to the brickwork with nails 7, they are driven into wooden plugs 6 embedded in the wall 5, coated with an antiseptic. The advantage of walls with panel insulation is that there is no need to do internal plaster.

Walls with thermal liners consist of two brick walls: 1/2 brick each, between which ready-made blocks of low thermal conductivity, called thermal liners, are laid. Every 3-5 rows between the enclosing walls a connection is made using steel flat wire staples or bonded rows of masonry. Thermal liners are made from effective thermal insulation materials - foam concrete, foam silicate and others.

The advantages of such walls compared to brick-concrete walls are the smaller amount of moisture introduced when filling voids in the wall, as well as the possibility of their construction in winter.

The walls of the well masonry are erected from two walls 1/2 brick thick, connected to each other by vertical brick walls - a rigidity diaphragm. The wells formed in the masonry are filled with insulation.

Transverse brick walls 1/2 brick thick are installed at a distance of 53 to 105 cm, i.e. equal to 2-4 bricks. Wells are filled with backfill, lightweight concrete or lightweight concrete liners. To prevent settlement of the backfill, which reduces the heat-protective qualities of the wall, horizontal diaphragms 15 mm thick are installed every 400-500 mm along the height of the wall from a mortar of the same composition as the masonry mortar. Walls of this type are erected with a thickness from 380 mm to 560 mm.

Structural details of brick walls and masonry openings

The main structural details of brick walls are the base, cornices, smoke and ventilation ducts.

The base of the brick walls is a solid brickwork with a height of at least 400-500 mm above ground level. The waterproofing layer is installed according to general rules.

Cornices are made from ordinary masonry or prefabricated. Lintels over window and wooden openings are made of precast reinforced concrete. Reinforced concrete slabs, distributing the load on two walls, are placed under the ends of the floor beams, resting on walls 1/2 brick thick.

Smoke and ventilation ducts are installed in the internal walls, which are made of solid brickwork. Concrete blocks are also used to construct channels.

To install door and window frames, openings are left in the masonry, which are covered with precast reinforced concrete, ordinary brick or wedge lintels. When installing ordinary lintels at the level of the top of the opening, formwork is installed from boards 40-50 mm thick, on which the mortar is spread in a layer of up to 2 cm and reinforcement is laid (stack steel, round 4-6 mm) at the rate of 1 rod per 1/2 brick wall thickness .

The ends of the reinforcement should extend 25 cm into the walls. When laying openings in brick walls wedge lintels are also arranged on pre-laid formwork, laying the brick on an edge from the edges to the middle of the lintel and sloping at the edges to form a spacer (wedge). It is allowed to install lintels made of tarred boards 5-6 cm thick, the ends of which should be buried 15-25 cm into the walls.

Which brick is better to choose for walls?

In this section of the article you will learn which brick is better for walls and what are the features of masonry made from different types of bricks.

How are bricks classified according to their purpose?

Which brick to choose for the walls depends on the purpose of the material. Ordinary brick is used for internal rows of masonry or for external rows, but with subsequent plastering.

Ordinary brick may have a pressed geometric pattern on the side (for better adhesion to the plaster mortar.

The facing brick is of a uniform color, has two smooth, even facing surfaces “poke” and “spoon”. It is, as a rule, hollow, which makes a wall made of such brick warmer.

Facing bricks include textured bricks with a relief pattern on the front surface. And shaped, or figured, profile is intended for laying complex shapes: arches, pillars, etc.

What are the features of working with various types bricks?

Hollow brick has less mass and, as a result, less load on the foundation. But during laying, the holes can become clogged with mortar, and it will become “colder”. To avoid this, you need to take bricks with voids of a smaller diameter and a more viscous mortar. Brick can be made even “warmer” due to internal porosity. Such a brick is called porous. To save time and money, it is better to buy not an ordinary brick, but a one-and-a-half brick. But you can choose the color according to your taste - this does not affect the quality of the brick.

How are porous bricks made?

To reduce the mass of bricks, as well as to increase their heat-shielding properties, sawdust is added to the raw material during the production process, which, when burned out during firing, creates micropores. The brick becomes “warmer” due to the internal porosity of the material. Compared to ordinary brick, porous brick has a lower density, due to which it has better thermal and sound insulation properties. In addition to bricks, porous stones are also produced (including large format -510x260x219mm), intended for laying external walls.

What brand of brick is needed for the walls?

What brand of brick is needed for the walls and what does the brand of brick indicate?

If strength is the ability of a material to resist stress and deformation without breaking, then the grade is an indicator of strength. It is designated by the letter “M” with a numerical value. The numbers show how much load per 1 cm2 a brick can withstand.

For example, grade 100 (M100) means that the brick is guaranteed to withstand a load of 100 kg per 1 cm2. The brick can have a grade from 75 to 300.

The most common bricks on sale are M100, 125, 150, 175. For example, for the construction of multi-story buildings, bricks of at least M150 are used. But for a cottage of 2-3 floors, “one hundred square meters” (that is, M100) is enough.

What brick should be used to build a cottage?

It is useful for any developer to know that: for construction in the Moscow region, you need a brick with frost resistance of at least 35 cycles, and even better 50; semi-dry pressed brick with frost resistance of 15 cycles is not suitable for cladding walls and laying foundations.

You can distinguish it from a plastic molded brick by its “bed” (the largest side): it is smooth and has conical, non-through voids. This type of brick is best used only for internal partitions. If, after all, it was used for cladding, then it must be done immediately.

Plaster, of course, will not create a complete finish, but it will protect the brick walls for some time; for the construction of a two- or three-story house, M100-125 brick is required; facing bricks should be purchased of the same brand as building bricks, because the entire wall must be of the same strength; double brick is cheaper than single brick, and additionally, mortar and laying time are saved; porous brick is “warmer” than a simple hollow brick; It is advisable to buy all the facing bricks at once, in one batch, so that all the cladding is uniform in color; the color of the clay is not related to the quality of the brick, so buy a brick of the color you like; for windows, arches, window sills, fences, etc. there is a special shaped brick; It is not recommended to build a foundation from sand-lime brick: it is not resistant to moisture. You cannot make stoves and pipes from it - it begins to decompose under the influence of high temperatures. And it’s difficult to plaster (it’s very smooth), so the solution doesn’t stick to it well.

Is it more profitable to purchase bricks directly from the manufacturer?

Of course, buying from a brick factory will be cheaper, although you will have to pay a lot for transport. In trading companies, bricks cost on average 15% more than at the factory, but this price also includes delivery to the site. In addition, companies practice discounts. In construction markets, where you can buy bricks individually, their price can be two times higher than at the factory. Please note that the higher the brand, the more expensive the brick. For example, M125 brick is about 10% more expensive than M100. The difference in price between “one hundredth” and “two hundredth” brands can be 20-30%. It is more profitable to buy ceramic stones or double bricks. The relationship here is approximately this: increasing the size of a brick by 50% increases its price by 20%.

How to identify a defective brick?

According to GOST, defective bricks are overburned and underburned, and such bricks are not recommended for sale. How do you know if a red brick is fired correctly? If the core of the brick is a more saturated color than the “body” and rings when struck, then this is a good quality brick. Unburned brick has a characteristic mustard color and makes a dull sound when struck. Unfired brick has low frost resistance and is afraid of moisture. A burnt brick turns black, melts, loses the clarity of its lines and size, and “bursts” from the inside. But experts say that if a brick has not broken its shape, and only its core turns out to be black, then it, on the contrary, becomes simply iron. It is used for masonry in damp places.

External walls made of sand-lime brick and their frost resistance

What is sand-lime brick and where is it used?

Sand-lime brick consists of a mixture of sand (about 90%), lime (about 10%) and various additives. It is used for laying stone and reinforced stone external and internal walls of buildings and structures, as well as for their cladding. Sand-lime brick is not used for walls in conditions of high humidity, since it absorbs moisture well, as well as for masonry exposed to high temperatures, since this causes decomposition of its components.

Sand-lime brick has high strength and thermal conductivity (higher than ceramic brick). In terms of strength, silicate products are manufactured in the following grades: 75, 100, 125, 150, 175, 200, 250, 300. The same as ceramic bricks, silicate ones are made with facial and ordinary ones.

What does the concept of “frost resistance of brick” mean?

Frost resistance is the ability of a material to withstand alternate freezing and thawing when wet. Frost resistance of bricks for external walls (designation “Mrz”) is measured in cycles. During standard tests, a brick is immersed in water for 8 hours, then placed in water for 8 hours. freezer(this is one cycle). So, until the brick begins to lose mass and strength. Then the tests are stopped and a conclusion is made about the frost resistance of the brick. For Moscow construction projects, you need to use brick with frost resistance of at least 35 cycles, and better - 50.

Types of ligation of rows of bricks in masonry: single-row and multi-row

What is brick bonding in the masonry of building walls?

To give the brickwork strength and solidity, a certain order of laying bricks relative to each other is used, which is called dressing. There are different dressings for vertical, longitudinal and transverse sutures.

Bandaging of longitudinal seams is necessary to prevent vertical “delamination” of the wall and to more evenly distribute loads along the length of the wall.

Bandaging the transverse seams is performed to create a longitudinal connection between the bricks. In addition, the transverse ligation serves to distribute the load across the entire thickness of the brickwork. The most common types of brick ligation are single-row (chain) and multi-row.

Single-row brick bonding is characterized by alternating spoon and butt rows of brickwork. In this case, the transverse seams in adjacent rows are shifted by a quarter of a brick relative to each other, and the longitudinal seams by half a brick. The vertical seams of the underlying row are overlapped by the bricks of the upper row.

When multi-row dressing of brickwork, the bonded rows are placed in several spoon rows.

Is the specified order of tying rows of bricks always maintained during laying?

There are restrictions on the number of spoon rows between bond rows, depending on the thickness of the brick. For single brick masonry (65 mm) - one row of joints per six rows of brickwork. For masonry made of thickened brick (88 mm) - one row of joints per five rows of brickwork. In this case, the vertical seams in four rows of spoons are overlapped by the spoons of adjacent rows by half a brick, and the seams of the top row are overlapped by the pokes of the sixth row by a quarter of a brick. This kind of brickwork is called five-row. However, such a dressing is only feasible if the wall is at least as thick as a brick.

Methods of laying bricks “clamped” and “butt”

What is the “clamped” method of laying bricks?

There are several ways to lay bricks, the main ones being “pressed” and “butt”. They are determined by the degree of plasticity of the solution.

The “pressed” method is suitable for masonry using a rigid mortar (7-9 cm of cone slump) with complete filling and subsequent jointing. In this case, the mortar is spread at a distance of 10-15 mm from the front surface of the wall and then leveled with a trowel in the direction from the previously laid brick in order to prepare a mortar bed for several bricks. After that, using the edge of the trowel, part of the mortar is raked up to the previously laid brick and pressed against its vertical edge. The next brick is lowered onto the bed and pressed against the trowel blade. After this, the trowel is sharply removed, and the mortar is fixed between the vertical edges of the bricks. Next, the brick is settled on the bed, and the excess mortar is trimmed with a trowel. The result is durable brickwork with full filling of joints.

What does the “end-to-end” brick laying method look like?

The “end-to-end” method is used when laying on a movable mortar (12-13 cm of cone slump) with incomplete filling of the seams on the front side of the wall, i.e., empty seam. In this case, the solution is raked from the bed directly onto the edge of the brick, starting at a distance of 8-12 cm from the previously laid brick. The brick is pressed against the bed, and part of the mortar removed from it fills the vertical joint. Next, the brick settles on the bed. In this case, the mortar is spread with a distance of 20-30 mm from the front part of the wall and is not squeezed out during laying. The most labor-intensive is laying “in the clamp”, the least - “butt”.

Features of brick wall masonry technology

When can I start laying a brick wall?

First, lay out the bricks along the pre-marked perimeter of the masonry, approximately observing the dimensions of the seam, which can be from 8 to 12 mm. Laying begins from one of the corners. The first 3-4 bricks are laid on it at an angle of 90°.

![]()

At the opposite corner in the direction of the masonry, 2-3 lighthouse bricks are placed. In the gaps between the bricks of the initial corner of the masonry and the beacon bricks, nails are inserted, on which a cord is pulled at a distance of 2-3 mm from the outer edge.

![]()

If the building has interior walls, then bricks are laid in appropriate places along the foundation, serving as the basis for the adjoining walls. It is very important to lay the first row of masonry correctly and evenly.

What are the technology features when laying brick walls in the second and subsequent rows?

Masonry technology has several options. Some craftsmen lay out a row of 2-4 bricks high along the first side, then lay out the next corner, transfer the beacon bricks to the next corner and thus sequentially go through all sides of the masonry. Other craftsmen first of all strive to lay the first row of bricks along the entire perimeter, carefully check the rectangularity of the masonry in plan and only after that “go” to the height.

How to achieve strength and stability of a thin brick wall?

If the brickwork is made in half or a quarter brick, it must be reinforced with metal mesh or reinforcing wire. Place in seams in 4-6 rows.

Necessary construction tools for bricklaying

Which is necessary construction tool does a mason use to lay bricks?

The main tools for bricklaying are a trowel (trowel), a hammer-pick and a jointing trowel (a steel spatula with a wooden handle).

It is used to level the mortar, fill vertical joints of brickwork with it and trim excess mortar. If there is a need to cut a whole brick into pieces, use a hammer-pick.

To control the quality of brickwork, a plumb line, a rule, a level, a cord-mooring line and an order are used. The plumb line is used to check the verticality of the brickwork. The level is used to control the horizontalness of the masonry surface.

Using a rule (a smooth wooden strip 1.2-2 meters long) the front surface of the brickwork is controlled.

Mooring cord is a twisted cord (3 mm in diameter) that is pulled between rows. It is used to ensure straightness and levelness of brick courses and to control the thickness of horizontal joints.

The order is two wooden or metal slats, on which serifs are applied at intervals of 77 mm (for a single brick). This distance is the sum of the thickness of the brick (65 mm) and the thickness of the seam (12 mm). An order is used to mark the rows of brickwork, and if there are openings, to determine their dimensions on the brickwork, the order is secured with special steel bracket holders with a transverse bar.

What quality of mortar is needed for brickwork?

What mortar is needed for brickwork to ensure the strength of the building?

To fasten the bricks together, a mortar for brickwork is used, prepared from a mixture of cement and sand (the sand must be carefully sifted). The greater the proportion of cement in the solution, the less plastic it is (slowly mobile).

How to determine the quality of the masonry mortar and its required viscosity?

Mobility mortar for brickwork is determined by immersing a special reference cone into it (at 7-14 cm of cone draft). When laying hollow bricks, a mortar with a mobility of no more than 7-8 cm of cone slump is used. When laying solid bricks in hot weather, the mobility of the mortar should be increased to 12-14 cm of cone slump. In order to preserve all the qualities of the mortar before laying bricks, it must be thoroughly mixed, since over time, heavy particles settle, the mortar stratifies and becomes heterogeneous.

How is the mortar laid when laying bricks?

For high-quality brickwork, it is necessary to pay special attention to the uniform distribution of the mortar on the bed. The strength of the seam depends on the correct spreading. When making a spoon row, the solution is spread in a layer (bed) 80-100 mm wide, for a bonded row 200-220 mm. The thickness of the bed should be 15-20 mm, which ensures a seam thickness of 10-12 mm. Before laying, bricks are soaked in water for some time, since dry brick takes water from the mortar, which leads to a decrease in the strength of the brickwork.

Pustoshovka and jointing of brickwork, combating efflorescence

Why is seam unstitching done?

After laying a certain number of rows, but before the solution dries, the joints are opened. This is necessary to give the surface of the brickwork a clear pattern and compact the mortar in the joints of the brickwork. For such operations, jointing of brickwork with a working part of various configurations is used. In this case, rectangular recessed, convex, concave, triangular double-cut and other shapes of brickwork joints are obtained

What is a “wasteland”?

If the walls will be plastered in the future, then the masonry should be hollowed out, that is, without filling the seams at the surface of the wall to be plastered with mortar. Pustoshovka in brickwork provides stronger adhesion of the plaster to the wall surface.

What are efflorescences?

Many people have probably seen whitish stains on the brick walls of buildings. These are traces of calcium, magnesium, etc. salts originally contained in the clay. This is efflorescence on brickwork, and the intensity of their manifestations depends on the amount of salts contained in the bricks.

How to protect yourself from efflorescence?

There are many ways to combat efflorescence on brickwork, some of them are listed below:

- use a thick solution;

- do not spread the mortar on the façade of the brick;

- do not lay bricks during rain and cover fresh masonry at night;

- bring the house under the roof as quickly as possible;

- cover the façade with a protective compound.

B1 in English what level?

B1 in English what level? Managing verbs in German - German online - Start Deutsch

Managing verbs in German - German online - Start Deutsch Conjugation of the verb haben (to have) in the present tense

Conjugation of the verb haben (to have) in the present tense