Description and characteristics of one and a half bricks. Silicate building brick M150.

At first glance it may seem stupid, but before starting the construction of a residential and administrative building, it is necessary to determine the dimensions of the building material. This is important for several reasons, firstly, preliminary calculation allows you to save on the purchase of blocks, and secondly, you can create an object with all the features and subtleties.

A counter question arises: is there a difference in bricks if the materials used in production are different, but their dimensions are the same?

Popular building material

Brick is perhaps one of the most popular materials of our time; you can build anything from it, both a residential building and an industrial building. Of course, this is due to its characteristics: the ability to retain heat, strength, durability and moisture resistance.

For your information! For many, environmental friendliness is no less important than, for example, resistance to chemical influences, and this is another plus for the material. Ceramic and silicate blocks are environmentally friendly, do not emit harmful substances over time, and can be worked with without protective equipment on the face.

What is one and a half brick

If we talk in simple language, then this is a block slightly increased in height, it became necessary due to the increased demand for construction - people needed houses as soon as possible. By increasing the standard dimensions of one-and-a-half bricks to 250 mm length, 120 mm width and 88 mm height, manufacturers were able to provide a more practical material for everyone to see.

You may ask, it is only 23 mm in height, how can this be reflected in saving time?

- Savings are possible not only on time, but also on cement mortar. At first glance, this does not seem to be that much more than a one and a half block, but if you calculate the total area, it turns out to be quite an impressive number. Just imagine that three lorries are four ordinary blocks.

- The aesthetic aspect is also touched upon here, there are fewer seams, and “large” building materials, which also have an unusual texture, catch the eye.

Note! Building brick or double sand-lime brick M 150 allows the consumer to choose exactly what he wants. Modern products can have a smooth surface, a rough finish, a wood texture, and there are also differences in colors.

- If we are talking about one-and-a-half blocks, then we should divide them into two categories: hollow and solid. Let's say right away that solid bricks are considered ordinary, that is, they are used for interior work when hollow ones are used for cladding.

This is due to the lightness of the material, its increased ability to retain heat and be firmly fixed to cement.

Dimensions of building materials

Let's return to our question, what is the difference between ceramic and sand-lime bricks, given that the size of a sand-and-a-half brick is identical to a clay block?

For your information! The dimensions of one-and-a-half silicate bricks, which we indicated earlier: 250x120x88 mm (GOST 530-2007), are taken as a basis.

- The manufacturing process is the main point that can be called the main difference. If ceramic blocks are fired, silicate products are prepared by pressing.

- Color is another point. usually red (pinkish) in color when silicate ones are made with various additives. So, in hardware store, you can purchase yellow, brown, white and sand blocks.

- Density– ceramic bricks are considered more durable, but at the same time their cost is higher, and for many, price is the decisive factor when choosing.

Traditions

But our section is still tied to product sizes, to standards that have not changed for many years.

- Firstly, this is due to the convenience of masonry; after all, more mobile blocks are easier to move, transport and erect.

- Secondly, this size of one-and-a-half silicate brick allows you to spend less materials to build a wall of the required thickness.

For your information! The standard is considered brick wall 650 mm thick, with the use of insulation, this distance can be reduced to 340 mm.

Silicate one-and-a-half hollow block with a smooth surface and rounded corners

- So, for example, at the very beginning of its “existence” the silicate block was a little larger, especially in workshops remote from large cities. Manufacturers diluted the material with all sorts of secondary raw materials, saving on good-quality materials.

- Then, on the contrary, the time came for complete savings, everything building bricks became slightly smaller in size, this also affected silicate blocks. So manufacturers wanted to force consumers to purchase as many goods as possible, while paying round sums.

Conclusion

As for how to use it, there are special instructions for this in addition to it.

Brick is a word that was borrowed from Turkic. Before people started using bricks, they used plinths. Plintha is a wide clay plate, the thickness of which is 2.5 centimeters. It was made in wooden forms. The plinth was dried for about two weeks, and then it was placed in a kiln and fired. Many manufacturers put their marks on the plinths. Unfired bricks were also widely used, which were made from clay and straw, but were not fired after drying. Burnt brick was used in construction in ancient times - 3-2 thousand BC. in Egypt.

IN Ancient Rome and Mesopotamia, 10/30/45 cm bricks were used to create complex structures, vaults and arches. The shape and size of the brick could be different - round, rectangular, triangular. Triangular bricks were used to create good and reliable figured masonry. A triangular brick was created from a rectangular one, which was cut radially into 6 or 8 parts. At the end of the 15th century, baked bricks began to be used in Rus' - an example of this is the walls and temples of the Moscow Kremlin. In the 16th century, the brick to which everyone was accustomed appeared in England. The small size and rectangular shape ensured convenience during the construction process.

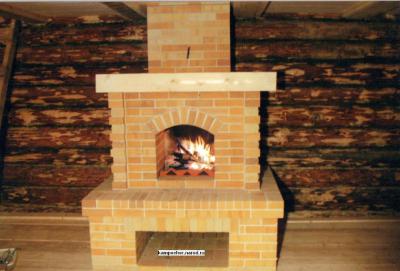

With the help of stoves and fireplaces you can create coziness in your home, make it family-friendly, comfortable and warm. Red brick, which comes in different sizes, is used not only for the construction of stoves and fireplaces, but also for other structures that are exposed to very high temperatures. Red brick can easily withstand high temperatures - 1400-1800 degrees.

- Simple. This kind of brick differs from refractory brick in that it heats up faster and tolerates temperature changes well. Simple brick is used to create stoves and fireplaces because they heat the house and must give off heat well.

- Refractory. Such bricks are created from special, high-strength types of clay using the hardening method. It tolerates high temperatures well and can be used in areas where the temperature may be too high.

The size of red bricks could be different until the beginning of the 19th century, but then standards appeared - 65/120/250 millimeters. This single brick size is considered NF - normal format. Such dimensions are considered the best for transverse-longitudinal masonry of walls.

Each face of a brick, according to GOST 530-2007, has its own name: poke, spoon, bed. Several more types of bricks were developed from NF:

- 1.4 NF – one and a half;

- 0.7 NF – euro;

- 2.1 NF – double.

One-and-a-half bricks, the sizes of which differ from NF, are very often used for the construction of various fireplaces and stoves.

Many people involved in construction recognize only clay red and silicate white. What are the differences between them? They are exactly the same size and shape. Clay is used to create red bricks, and sand and lime are used to create white bricks, so their properties are completely different. There are three types of silicate white brick sizes.

This type of brick is becoming more and more popular and in demand today. Low cost, excellent characteristics. Today there are very high demands on building materials. Sand-lime brick is used for the construction of tall residential buildings, as well as various cottages.

The most popular are single and one-and-a-half bricks. The size of single sand-lime brick is 65/120/250 mm. It is used to build houses of varying complexity. The size of one-and-a-half sand-lime brick is 88/120/250. Brick of double sizes - 138/120/250 is used very rarely in construction. There are brick manufacturers who offer their customers other sizes if necessary. The dimensions of white sand-lime brick allow builders to create strong and reliable buildings.

The most popular are single and one-and-a-half bricks. The size of single sand-lime brick is 65/120/250 mm. It is used to build houses of varying complexity. The size of one-and-a-half sand-lime brick is 88/120/250. Brick of double sizes - 138/120/250 is used very rarely in construction. There are brick manufacturers who offer their customers other sizes if necessary. The dimensions of white sand-lime brick allow builders to create strong and reliable buildings.

| Type of brick | Dimensions, mm | Weight, kg |

| Ceramic facing brick | 250*120*65 | 2.7 (hollow) |

| 250*120*65 | 3.7 (full) | |

| 250*85*65 (Euro) | 2.2 (hollow) | |

| Thickened ceramic facing brick | 250*120*88 | 3.7 (hollow) |

| 250*85*88 (Euro) | 3.1 (hollow) | |

| Clinker facing brick | 250x120x65 | 4.2 (full) |

| 250*90*65 | 2.2 (hollow) | |

| 250*60*65 | 1.7 (hollow) | |

| Clinker facing brick (long) | 528x108x37 | 3,75 |

| Hyper-pressed (non-firing) brick, solid, smooth | 250*120*65 | 4,2 |

| 250*60*65 | 2 | |

| 250*90*65 | 4 | |

| Hyper-pressed (non-firing) brick, solid, smooth, thickened | 250*120*88 | 6 |

| Handmade ceramic brick | 188*88*63 | 1,9 |

All people who want to create a fireplace or stove in their home on their own know how difficult it is to do this. Those who are faced with this task for the first time may not always choose the right materials that are needed for the fireplace, which can cause many surprises and problems.

Where is fireclay, fire-resistant brick used and what is its purpose? To create a stove in the house, you should choose alumina types of fireclay bricks, which are made from special clay - fireproof (it is also called fireclay) and a mixture of quartz.

The composition of fireclay bricks mainly consists of 70% refractory clay, so the properties of such bricks are very high and they are resistant to temperatures. The brick is fired at high temperatures, and to ensure the creation process is accurate, they use computer technology and the latest equipment.

During the manufacturing process of bricks, the temperature must remain at the same level, because any changes in temperature can cause the brick to form a glass-like film, which will complicate and make laying such bricks simply unrealistic, since the mortar simply cannot hold. Brick with film has a slightly specific color, which is why its builders call it iron ore. This type of brick is used to create plinths because it repels water very well.

Ordinary bricks, which are used to create fireplaces, stoves and other buildings, have a yellow-straw hue. They are also distinguished by their unusual granular structure, as well as the density of their structure.

Refractory brick sizes can be different, in addition, this type of product can withstand not only high temperatures and temperature changes, but also chemical aggressive environments for a long time.

In addition to all the previous characteristics of refractory bricks, it has one more advantage - the ability to accumulate all the heat that it receives. This ability allows the stove to warm up slowly and distribute heat evenly throughout the rooms and maintain it at the same level. If you use other types of bricks for stoves and fireplaces, then there will be a constant temperature difference in the room, and sudden changes do not always have a good effect on health.

The quality of fireclay bricks must always remain at a high level, because they are used in very difficult places. You need to choose this type of brick very carefully and responsibly. To check the quality of the product, you should knock on it - if it makes a metallic sound, this means that everything is good and it can be used. When you hit a brick, it should also easily and quickly break into small pieces. If a refractory brick does not meet at least one of these requirements, then its quality is poor and it is better not to use it, since it is unknown by whom and under what conditions it was created. Standard brick size is 65/120/250 mm.

The quality of fireclay bricks must always remain at a high level, because they are used in very difficult places. You need to choose this type of brick very carefully and responsibly. To check the quality of the product, you should knock on it - if it makes a metallic sound, this means that everything is good and it can be used. When you hit a brick, it should also easily and quickly break into small pieces. If a refractory brick does not meet at least one of these requirements, then its quality is poor and it is better not to use it, since it is unknown by whom and under what conditions it was created. Standard brick size is 65/120/250 mm.

If these main quality indicators are simply absent, then the manufacturer produces poor products using artisanal methods that produce poor and low-quality brick firing. If the manufacturing process was not at the required temperature, the brick turns out to be of poor quality and cannot meet all norms and standards. And all stoves and fireplaces will only last a few years, because then they will simply fall apart.

The weight of refractory bricks should be greater than that of ceramic bricks. The weight of such a brick can be different - it starts from 6 and ends with 2.4 kilograms.

| Type of brick | Dimensions, mm | Weight, kg |

| Fireclay brick | 230*113*65 | 3,4 |

| 230*123*65 | 4 |

In the modern construction market there is a huge number various materials, each of which has its own unique characteristics. Sand-lime brick is one of the most popular materials for finishing facades and cladding buildings. The size of white sand-lime brick, as well as some of its other parameters, may vary. Before purchasing this material for construction, it is worth familiarizing yourself with its features in more detail.

Types of silicate white bricks

Before asking the question - how much does silicate cost? white brick, you need to understand that this is a very loose concept. There are several options for classifying this type of brick:

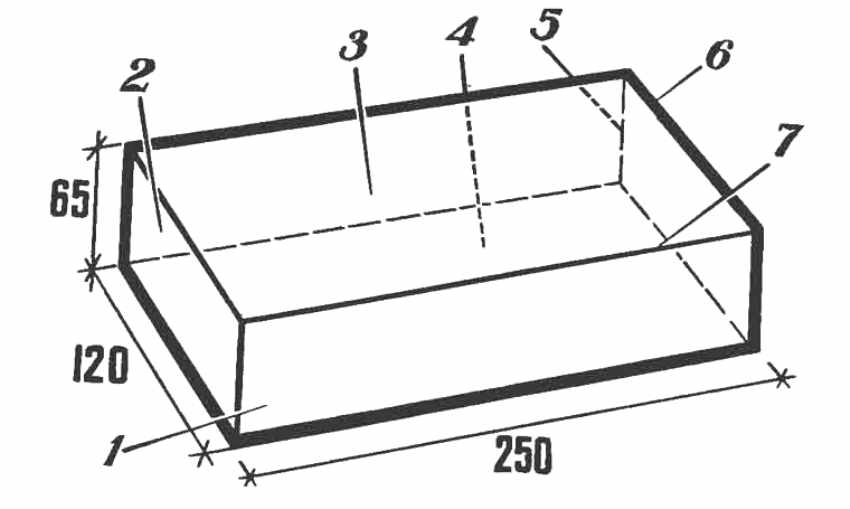

- in size - standard and one-and-a-half bricks. The parameters of the standard one are 250x120x65 mm, one and a half - 250x120x80 mm. It is also possible to produce sand-lime bricks of non-standard size if the customer needs it. The size of white sand-lime brick depends only on what kind of masonry you plan to do;

Dimensions of standard sand-lime brick and names of its sides: 1 - spoon, 2 - butt, 3 - upper bed, 4 - lower bed, 5 - vertical rib, 6 - horizontal transverse rib, 7 - horizontal longitudinal rib

Dimensions of standard sand-lime brick and names of its sides: 1 - spoon, 2 - butt, 3 - upper bed, 4 - lower bed, 5 - vertical rib, 6 - horizontal transverse rib, 7 - horizontal longitudinal rib

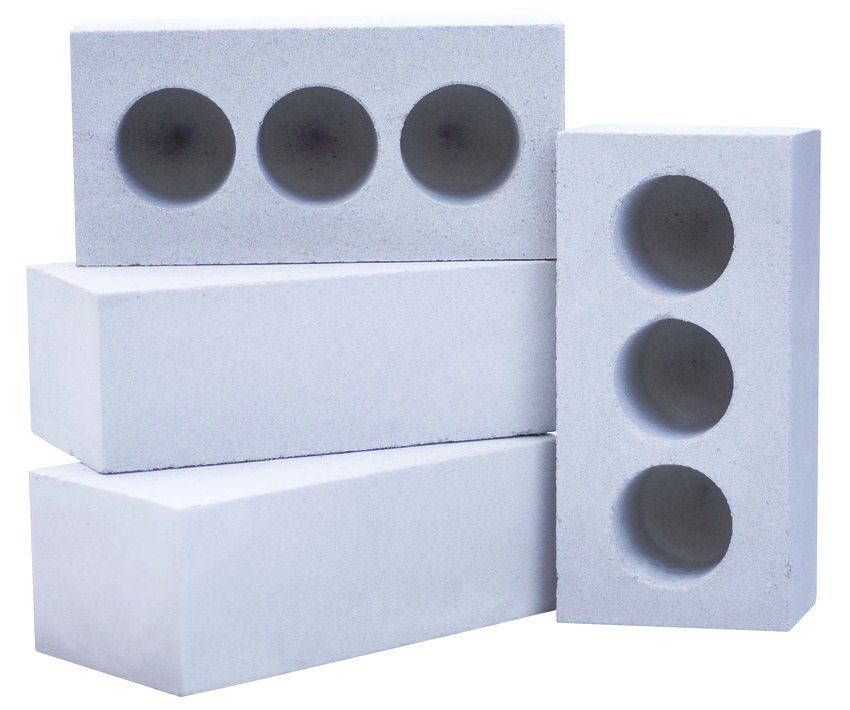

- in shape - hollow or solid. In the first option, there are round or rectangular recesses in the brick, which are located perpendicular to the widest edge of the product. If it is important to you how much white silicate bricks weigh, then it is better to choose the hollow option. By the way, it can be two-hollow or three-hollow. Solid sand-lime brick has a monolithic fill and, accordingly, weighs more;

- by area of destination - facing brick and special purpose bricks. It is logical that the first option is used for the purpose of cladding facades, but the second is used to create fireplaces, stoves, build ceilings, foundations and other structural elements.

When choosing the size of white sand-lime brick and its other characteristics, consider, first of all, the scope of application of the material. For example, hollow facing bricks are better suited for finishing the facade of a house. Monolithic brick is often used for foundations, as it can withstand heavy loads.

Main characteristics of sand-lime brick

Many people mistakenly believe that brick is a very simple product. In fact, even this building material has a lot of features. Before finding out the price per piece of white sand-lime brick, pay attention to the following performance characteristics:

- the presence of increased frost resistance - this parameter is useful if you are planning to build a house in cold winter conditions or simply sudden temperature changes;

- weight of white sand-lime bricks - hollow brick weighs a little more than 3 kg, one-and-a-half - 4 kg, standard solid - 3.5 kg, solid one-and-a-half - almost 5 kg;

- waterproofing properties of the material - as a rule, high-quality white silicate brick does not allow water to pass through, so it can be safely used for external finishing work, without fear that the facade will lose its attractiveness appearance because of the rain.

Useful advice! As for using sand-lime brick to build a stove or fireplace, you will have to act at your own peril and risk. Brick has a fairly high thermal conductivity, so structures made from it can deteriorate relatively quickly.

How does the size of white sand-lime brick affect the finishing features?

Whatever size of white sand-lime brick you choose, you should always take into account a number of nuances when laying:

- The seam between bricks should not be more than 1.3 cm.

- You should definitely leave a small space for ventilation between the masonry and the wall itself, this will help you avoid the accumulation of condensation on the bricks.

- Silicate absorbs moisture well, so brick mortar needs to be thick.

If you do not want your sand-lime brick walls to suffer from humidity and thereby lose their performance properties, then it is recommended to cover fresh masonry with special moisture-resistant solutions.

Otherwise, laying white sand-lime brick is quite simple. You can handle this on your own even if you have minimal construction skills.

Advantages and disadvantages of white sand-lime brick

White silicate-based brick is not without reason very popular among builders. Among its advantages are the following:

- reliability and durability;

- frost resistance, resistance to temperature changes and other unfavorable natural factors;

- large selection of color options;

- unpretentiousness and ease of installation and operation.

Also, sand-lime brick provides in the house high level thermal insulation, resistant to mechanical stress. The disadvantages include a low level of heat resistance, which can make it quite problematic to use such bricks for building stoves and fireplaces.

Useful advice! When cladding the facade, it is best to use hollow bricks of standard sizes. This will allow you not only to save on material, but also to end up with a fairly lightweight structure.

The price of white sand-lime bricks is not too high compared to other building materials. This allows them to be widely used without spending much money. That is why many builders choose white sand-lime brick as a building material for external and internal work. And its relatively light weight, combined with excellent performance characteristics, make brick very popular for the construction of a wide range of buildings.

White (more correctly called silicate) brick began to be produced at the beginning of the 20th century. And although today’s market is filled with various wall building materials, this type of brick, as before, is in great demand. There are many reasons for this popularity. These are simplicity and reliability in operation, inexpensive price, aesthetics, relative durability and strength, as well as a variety of shapes.

Its production is very economical, since it consists of 90% sand, and the remaining 10% is lime and a small proportion of additives. It is produced by autoclave synthesis. Silicate is an environmentally friendly product, as it is made from natural materials, so its use in construction is not only profitable, but also safe.

You can learn about which brick is best to build a stove from this

It meets all the requirements of world standards. Its production is famous for its dimensional accuracy.

In many respects it is not inferior to ceramic, and in some properties it is superior. For example, it has increased sound insulation and is quite frost-resistant.

Reviews about ceramic brick can be found in this

The density and strength of white brick is high, although lower than that of red brick. It is usually denoted by the letter M. For example, M75 for low density, and M250 for the highest.

There are also special brands to indicate frost resistance. Therefore, you can always choose exactly the material that is needed for certain jobs.

The video talks about one-and-a-half white silicate bricks:

What disadvantages of sand-lime brick can be described

Silicate is also divided into types such as ordinary and finishing, depending on its application. And the shape can be single, one-and-a-half or double, which is very good for reducing construction time. With the addition of dyes, this building material can be not only white, but also have a wide variety of colors. Silicate is also produced in the form of different geometric shapes: oval, angular, round. So the production of white brick is quite diverse.

Price

White silicate brick, depending on the type presented, can be purchased at a price of 12-14 rubles per piece. This price is not high, because such a set of advantages fully justifies it.

Sand-lime brick is a very popular and popular material in the field of construction. The reason for this demand is a large number of positive characteristics. The main advantages remain environmental friendliness, strength and resistance to precipitation. In addition, the constructed building will have a long service life.

Sand-lime brick - strong, reliable, durable and natural building material, which is produced 90% from sand and 10% from lime. It is inferior to its clay counterpart only in terms of versatility of use - it cannot be placed in places where there is high humidity or high temperature. But it can be used to build load-bearing walls, installation of partitions, decoration or soundproofing of the building during cladding. To calculate the project, it is important to know the size of white sand-lime brick and its quantity per linear meter, especially considering that it comes in several types with different characteristics.

Construction products are divided into solid and hollow. They differ in strength grades and thermal conductivity, but have standard sizes: single, one-and-a-half or double (thickened).

Construction products are divided into solid and hollow. They differ in strength grades and thermal conductivity, but have standard sizes: single, one-and-a-half or double (thickened).

There are 5 strength classes by brand: M75, M100, M125, M200, M250 and M300. The numbers indicate the permissible load in kg per cm2. The presence of voids has little effect on reliability, durability, and resistance, since a tested product with corresponding GOST characteristics is allowed for sale. But still, monoliths initially have grades from M150 to M300, and porous blocks - from M75 to M150.

Solid brick is a small block without grooves, monolithic, has high strength, frost resistance up to F50, significant density - about 1,700 - 2,200 kg/m3. It is advisable to use it for the construction of load-bearing walls in private 2-3-story construction. The dimensions of thickened silicate brick make it possible to use it for the construction of high-rise buildings and structures that require reliability and durability.

Solid brick is a small block without grooves, monolithic, has high strength, frost resistance up to F50, significant density - about 1,700 - 2,200 kg/m3. It is advisable to use it for the construction of load-bearing walls in private 2-3-story construction. The dimensions of thickened silicate brick make it possible to use it for the construction of high-rise buildings and structures that require reliability and durability.

Monolithic bricks are used less and less for private construction, since the strength characteristics of its hollow counterpart are sufficient to build a 2-story cottage. High-rise buildings are created using other technologies - from reinforced concrete products, which is much faster. However, the standard size of sand-lime double brick is attractive for exterior masonry load-bearing structures, chimney pipes, base, columns, stairs.

It should be borne in mind that a monolithic product has high thermal conductivity, which is why it is necessary to either make walls about a meter (which is expensive and time-consuming) or use porous material.

Hollow sand-lime brick has through holes or closed holes on one side, has lower thermal conductivity (this is its biggest advantage), density - 1300 kg/cm2, frost resistance from F25. It is used as the main construction and facing material. A combination of two types is often used: solid - on the outside of the wall, hollow - on the inside.

Hollow sand-lime brick has through holes or closed holes on one side, has lower thermal conductivity (this is its biggest advantage), density - 1300 kg/cm2, frost resistance from F25. It is used as the main construction and facing material. A combination of two types is often used: solid - on the outside of the wall, hollow - on the inside.

As practice has shown, the sizes of silicate one-and-a-half bricks are the most attractive and optimal for private low-rise construction in terms of price, strength characteristics and laying speed. Therefore, many, in order to save time and not overpay for additional volume of stone and unnecessary construction work, use white silicate hollow brick M-150 (size 250×120×88 mm) - the optimal strength grade with frost resistance F35.

Project calculation

In order to determine how much material you need to purchase for construction, you can use the indicative table:

Buy in Moscow

The price of white sand-lime single brick depends on the brand and type, but does not differ significantly, as can be seen from the table. The same can be said about one-and-a-half and thickened stones.

| Product type | Parameters, mm | Brand | Approximate cost in rubles/pcs. |

| full-bodied | 250×120×65 | M 150 | 8,3 |

| M 200 | 8,5 | ||

| M 250 | 8,7 | ||

| 250×120×88 | M 150 | 10,3 | |

| M 200 | 10,5 | ||

| M 250 | 10,7 | ||

| 250×120×65 | M 150 | 11,3 | |

| M 200 | 11,5 | ||

| M 250 | 11,7 | ||

| hollow | 250×120×65 | M 100 | 8,5 |

| M 125 | 9,5 | ||

| M 150 | 9,8 | ||

| 250×120×88 | M 100 | 8,7 | |

| M 125 | 9,2 | ||

| M 150 | 10,9 | ||

| 250×120×65 | M 150 | 10,4 | |

| M 200 | 11,5 |

Harmful working conditions Documents confirming work in hazardous working conditions

Harmful working conditions Documents confirming work in hazardous working conditions Topic in German “Umwelt” (Environment) Message in German on the topic of nature

Topic in German “Umwelt” (Environment) Message in German on the topic of nature How do you understand the main idea of the excerpt from the poem N

How do you understand the main idea of the excerpt from the poem N