Coaxial chimney for a wood-burning fireplace. Determining the size and shape of a brick chimney. Requirements for chimneys.

A correctly designed fireplace smoke exhaust system determines whether it will smoke when lit, quickly reach operating capacity, and also burn well even in rainy weather. Not all chimneys can ensure the functionality of fireplace equipment to the same extent. If we consider all the thermal characteristics, we can come to the conclusion that ceramic chimneys for fireplaces are best suited.

Understand how they work. This is the so-called mouth, the dimensions of which will be determined by the location where it will be implanted. The bottom of this chamber consists of a 45 degree inclined wall. Its purpose is to push heat waves towards the floor of the room and cause smoke to rise up the chimney.

From there, warm air, which is lighter and tends to rise, increases the temperature of the place. Due to the high temperature, it is necessary to use fireproof compound or cement during grouting. It is located directly above the firebox. Use caution to ensure that children do not play with fire or that flammable objects or foods are left nearby.

Is it possible to connect a fireplace to a ceramic chimney?

Fireplace chimneys made of ceramics provide a stable draft force and an almost complete absence of condensation. The main task of the smoke exhaust system is to remove combustion products in full, as well as to prevent smoke and burning smell from entering the room. Ceramic chimneys successfully cope with all these tasks.The connection of a ceramic pipe will not always be the best solution. The opinions of experts regarding the choice of a smoke exhaust system, depending on the type of fuel used, are as follows:

Its shape, like a funnel with a top, traps the cold air that typically comes from the outside environment, trapping smoke to be forced out. Fundamental at this stage is the presence of a throat, an adjustable opening whose dimension must be exactly equal to the cross-sectional area of the channel.

Errors in construction

A metal channel is more suitable than masonry. Because it is smooth, the material does not retain dirt or live corners, making it easier to smoke, and a stone chimney may contain excess soot - as it is not always possible to create a refined interior finish at certain times.

- Gas fireplaces – this equipment is characterized by the production of low temperature flue gases. The optimal solution when operating a gas fireplace is to choose an insulated sandwich pipe.

- Coal equipment – the process of burning coal releases a large amount of thermal energy. The smoke exhaust system connected in this case must withstand constant heating of 600°C and short-term heating (when soot burns) up to 1000°C.

A brick chimney meets all these requirements, but has one drawback - a short service life. Preference should be given to connecting the fireplace to a ceramic chimney in expanded clay concrete blocks. - Wood-burning fireplaces - during the burning of wood, so-called “white smoke” is released. As a result, a large amount of condensate is produced, even with an insulated chimney. The pipe used to exhaust smoke must be acid-resistant and able to withstand high heat. Due to these properties, ceramic pipes for fireplace chimneys are the optimal solution.

Pros and cons of a ceramic chimney by the fireplace

Ceramic pipes, like other smoke removal systems, have their positive and negative aspects which must be taken into account when choosing. The advantages include:

The disadvantages include:

- Large weight of the structure - the ceramic pipe, with the exception of some modifications, is enclosed in blocks, which only increases the weight of the structure. Before installation, you will need to make a foundation.

In wooden houses, as well as in frame buildings, it is recommended to use lightweight block-ceramic chimneys. Lightweight pipe structures can be installed on wooden base or a specially installed installation site. - High cost - compared to a sandwich pipe, the cost of the structure is approximately twice as high.

- Difficult installation - installing ceramic chimney blocks must be done extremely carefully. The joints are treated with a special sealant. The blocks are fixed using a heat-resistant clay-based adhesive solution. Subsequent finishing of the ceramic chimney with tiles or heat-resistant plaster is mandatory.

Main features of installing a fireplace with a ceramic chimney

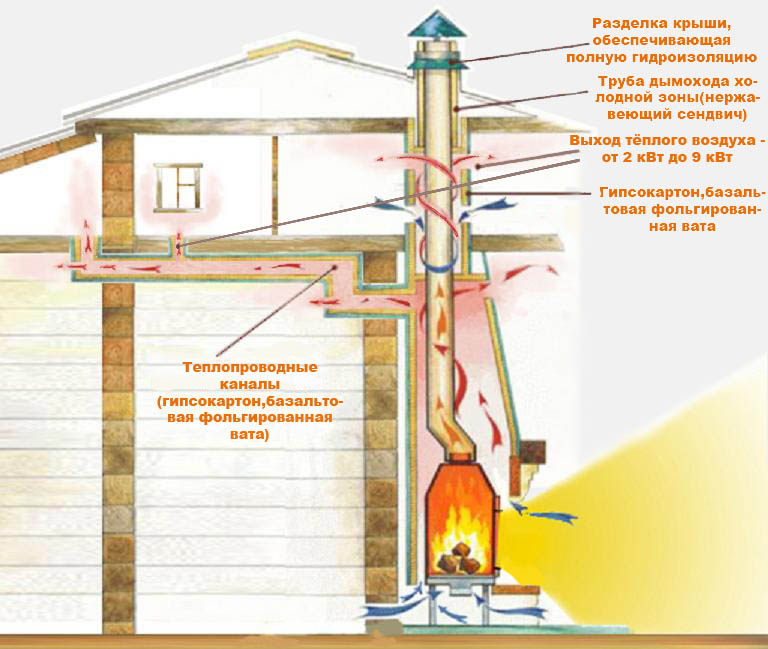

Connecting a fireplace correctly with your own hands is quite difficult, but if you have certain technical skills, it is quite possible. But before you begin installation work, you will need to consider several important nuances, as well as design features of fireplace inserts and portals.Additionally, the required diameter of the ceramic chimney, the height of the pipe are calculated, and a decision is made on the internal or external installation method.

The pipe must be the same diameter from the fireplace to the roof and always straight. If a bypass is necessary, the channel must first rise about 1 meter; Then make a 45 degree curve. However, only two route deviations in the pipeline are allowed. IN one-story house The height of the chimney should be at least 40 cm above the ridge, or higher when there is obstruction in the surrounding area, such as other houses and trees.

Smoke channel location

Ideal launch even on windy days. The section of the chimney that best exhausts the smoke should circulate. Due to the complexity of its implementation, you can use square shape. It is completely inappropriate to use a rectangular section or other geometric shapes.

How to connect a fireplace insert to a ceramic chimney

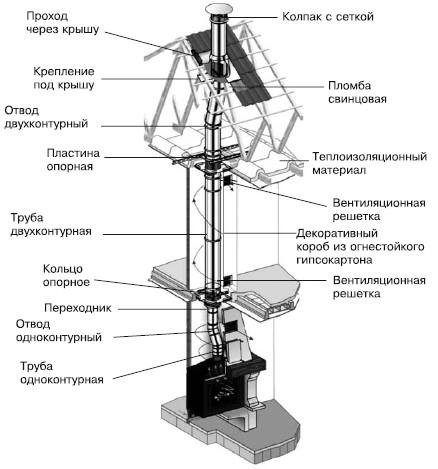

Installation of a ceramic chimney next to the fireplace for connection to the firebox requires compliance special conditions. Installation is carried out as follows:- The choice of pipe diameter depends on the manufacturer's recommendations.

- Preparation of a construction project - the operating instructions indicate only standard solutions, but depending on the characteristics of the building, an individual project may be required.

- The calculation of a ceramic chimney for a cast iron fireplace with an open or closed firebox is carried out in accordance with the manufacturers’ recommendations. IN technical documentation minimum parameters are indicated: recommended draft, offsets and safe distances. All requirements must be met.

- Installation is carried out from the firebox - first, the connecting point of the ceramic chimney with the fireplace is connected. Next, the rest of the structure is assembled. The unit is often made of stainless steel, with minimum thickness 1 mm.

Connection and further installation of the chimney is carried out without narrowing the diameter of the pipe. The horizontal section of the pipeline should not be longer than 3 m.

Beautiful and cozy environment!

A warmth that unites, in addition to keeping everything warm, the room is very cozy and invites you to gather with family and friends around the fireplace for good conversation, lots of laughter, a great movie with hot chocolate and especially the perfect and romantic atmosphere for a couple date, cuddling fondue also for those who like to drink good wine!

Therefore, the cold is more than delicious! lol. Let's meet the models and get inspired! Ideal for those with limited space at home, it can be installed on cooking gas without creating smoke or mess. Some models, like this one in the photo, do without a chimney! Fixed glass piece, preventing any object or even carpet from falling into the fire!

How to connect a fireplace portal to a ceramic chimney

To install a ceramic chimney for a built-in fireplace insert, you must consider design features heating equipment. Typically, portals are made with a top connection.The ceramic chimney is installed to the fireplace and connected to the smoke exhaust system using stainless steel pipes or a special corrugated pipe made of heat-resistant steel. When connecting, it is necessary to ensure that condensate does not flow into the firebox by installing a condensate collector.

The most typical thing about fireplaces is that it burns wood. It could be a corner or a wall, but it has a job to install due to the exhaust system. This can be a corner or center, built into the wall or not. Older, has as its main disadvantage the fact of producing coals and smoke. Its operation is reminiscent of a barbecue: it is made with fire bricks and requires an exhaust duct for the smoke to escape, meaning it must be planned even during construction.

Chimney inspection and cleaning

Wood burning fireplaces require specialized labor to install. They can be made from sheet metal or brickwork. They have a low heat capacity compared to other types of fireplace. Little habits and tricks are necessary to get your fireplace lit quickly and without fire. First of all, make sure your chimney is empty and free of birds or other animals that usually make a home in these areas. Now separate the wood from the fireplace, but remember that it must be dry, otherwise the fireplace will produce a lot of smoke and is unlikely to make coals.

Which brand of ceramic chimney should I choose for my fireplace?

Only a few manufacturers offer ceramic pipes on the domestic market. The most popular products are considered to be from the following companies:- is a German manufacturer that is the European leader in the manufacture of ceramic chimneys. The guaranteed service life of the Schiedel smoke exhaust system is at least 50 years.

- - another manufacturer from Germany. The Tona company is especially popular due to the special lightweight design of chimneys produced at the plant. The outer shell of Tona systems is made of stainless steel.

- – in wooden houses it is recommended to install Ultra Duplex Effe2 smoke exhaust systems. The special design allows you to simultaneously connect several fireplaces at once, combining them into a single network.

- Hart - the company has developed a whole line of ceramic chimneys designed for connection specifically to fireplace portals and fireboxes. In the design of Hart pipes, we managed to take into account all the nuances of operating fireplaces.

- Ecoosmose – the basis of the product is the use of isostatic and glazed pipes. Lightweight concrete blocks are used as the top layer, which significantly reduces the overall weight of the Ecoosmose structure.

Some manufacturers of fireplace portals directly recommend chimneys from one of the listed companies for connection. Otherwise, you will have to select a ceramic pipe yourself, based on the parameters specified in the documentation.

To improve the quality of the wood, always use pine knot when lighting your fireplace. Never let the fire take over, too much flame means heat is lost. The heat of the fireplace comes from the coals, so simply light the fire to create embers. To prevent accidents, it is recommended to use a safety lock on the fireplace. Never turn off your fireplace with water to avoid damaging it. With dry wood stored in a ventilated area, you can tan using logs.

Never use flammable products as they will cause the fire to last too long. If you're still having trouble lighting the fire, try using gas logs. They have a design that imitates wood and still produces heat for environment.

Answers to frequently asked questions about chimneys for fireplaces

During the operation of ceramic chimneys, a certain number of different opinions have accumulated, allowing one to form a general picture of the feasibility of using these systems. As practice shows, most buyers choosing a chimney ask the same questions. Representatives of specialized installation teams were asked to answer some of them.Which chimney is better for a fireplace - stainless steel or ceramic?

Connecting a fireplace insert to a ceramic chimney is the best solution due to the following aspects:- Service life – ceramics will last at least half a century. The service life of stainless steel will be no more than 20-25 years.

- Technical characteristics - stainless pipes, when exposed to high temperatures, deform over time, which is especially critical for joints. The tightness of the connections is gradually lost. Ceramics have no such disadvantage.

- Stainless steel chimneys differ from ceramic ones in thermal characteristics. Even when using high-quality thermal insulation, condensate is still produced in steel pipes in a larger volume than in ceramics.

Fireplace chimney – brickwork or ceramics?

Chimneys for fireplaces made of expanded clay concrete blocks have a structure somewhat reminiscent of brickwork. Brick is also made from clay and can withstand high temperatures. The weak point of masonry is often the seams between the bricks. Expanded clay blocks do not have this drawback.The service life of the masonry while maintaining the tightness of the system is 7-10 years. The design of a ceramic chimney for a fireplace is designed to last for half a century.

Covered with black granite and wallpaper or striped paint! When not in use or outside the winter season, leave the firewood inside as decorative items! Loved these white double tables! All covered with black glass tablets and steel pediment!

This fireplace occupies an unusual place - the middle of the white brickwork. Another highlight is the egg-colored metal plate that hides the hood and creates an air mattress that heats up when the fireplace is on. Hot air escapes through the gap in the stove and also brings heat into the environment. Project by Sergio Kipnis and Marina Greenover.

Does a ceramic chimney become clogged with soot?

The soot found in smoke is formed when solid fuel is burned. During the smoke removal process, soot settles on the unevenness and roughness of the internal contour of the pipes.A brick chimney is most susceptible to soot settling. After several years of use, the inner circuit of stainless steel pipes also begins to retain soot.

The neutral tones of the set harmonize with the dots of brighter colors present in the pillows and flowers Design by Cristina Barbara. Detail by the fireplace, log door! Capital table detail! And pendant lighting provides contrast in the fireplace! Detail with a green plant inside to decorate! With two washers light! Place decorative items with a shelf! Detail next to wood burning fireplace and other wood burning irons! The next door is a niche with lighting that also doubles as firewood! Great idea to close with special fireproof glass because it avoids any spark falling out on the carpet!

The ceramic pipe, even after time, maintains perfect smoothness interior walls. Although soot accumulates in a small amount, it is problematic to clog a ceramic chimney with it.

To maintain performance, it is enough to burn a special briquette once every 1-2 years containing chemicals that ensure maximum cleaning.

Detail objects above the fireplace and colorful painting, leaving the atmosphere fun, sophisticated and modern! The proposed solution was a composition of stickers in the masonry cabinet: the gold is highlighted black and brings volume to the set. Another great choice for decorating your fireplace is to add a decal! Wood door detail next to the fireplace! This fireplace optimizes storage space for items, books and home theaters! Colorful details just in colors and frames! Corner fireplace with custom glass door!

Super modern and warms up for both the room and the bench! Some items were placed for decoration! Ideal for country house! Detail of a chandelier with candles inside the fireplace and a wood burning door next to it! All dressed up in wallpaper with a mirror and a white frame with objects on top!

How to prevent sparks from flying out of a ceramic pipe

A spark arrester is installed on the head of the pipe. The device is a mesh with small cells. After installing the spark arrester, the thrust intensity does not change.The spark arrester prevents the emission of burning soot from the chimney and prevents the roof from catching fire. Industrial safety regulations require the installation of the device when installing bitumen and other flammable types of roofing.

Building codes for fireplace chimneys

Detail on side with iron door to move the tree! Rustic and modern, all brick! Lighting detail and shelves to the side with decorative items! All covered on top, wallpaper, tiles or porcelain tiles that imitate wood and niches with objects and lighting!

Detail of firewood as a decorative item! Everything is covered with white varnish! Detail of the blue bathtub inside the fireplace! It combined the excellent idea of placing two vibrant colors - blue and red - in the same environment! And the yellow detail on the frame brings more joy to the environment! With a beautiful understated nature themed frame! With frame and flower vase above! Closed with an iron door!

Some nuances of selection and connection can only be taken into account by specialists with experience in carrying out installation work. It is recommended to entrust the installation of ceramic smoke exhaust systems to professionals.

Calculation of power and temperature of a warm water floor

Selecting air conditioner power

Our task will be to provide useful information about possible pipe options, their advantages and disadvantages, which may be able to facilitate this choice.

Detail the white walls with a mirror on each side of the fireplace! Need a more cozy environment? lol. The fireplace is all covered with stones! Gas fireplaces operate like a regular fireplace, but are fueled by butane gas. His maintenance more expensive but safer than a regular fireplace as it does not produce soot, embers or sparks. Gas fireplaces are usually decorated with volcanic stones or fake logs to give the flames a more classic look.

Gas fireplace 70 cm long, running on natural gas. It heats up to an area of up to 24 m². It works connected to electrical point, and to a gas pipeline laid along the floor, ignited by electric ignition, activated by remote control. The flame heats the volcanic rock, which helps dissipate the heat. It consumes about 350 g of gas per hour of use.

Chimneys for brick fireplaces

Most often, in cottages, when installing pipes for fireplaces or boiler rooms, they use chimneys combined into a single block with ventilation risers. Red ceramic solid bricks are used to make them.

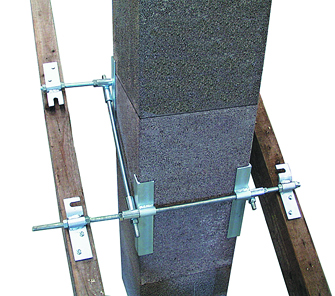

Features of the installation of brick pipes

A brick fireplace chimney, like a ventilation block, must rest on the foundation. It can serve as load-bearing wall or foundation slab.

Super cozy atmosphere! It works connected to a cylinder by pipes passing through the wall, ignited by an electric ignition. Comes with a safety valve that blocks the gas from escaping if there is a leak. Consumes about 400 g of gas per hour.

That is, a 13 kg bottle has enough fireplace fuel to run for about 32 hours. The table in the background also deserves attention: leaning against the wall, it serves as a buffet, since it can receive benches and dining room dining. There are many objects above and nearby, and a beautiful big picture and colorful! Detail of niches with lighting and drawers on each side of the fireplace!

When constructing such a structure, certain rules should be followed:

- lime-sand mortar is used for masonry;

- when inserting a chimney structure into a wall made of any material, it is anchored, adhering to a step of 30 cm (in a checkerboard pattern), inserting anchors into the walls by 20 cm and using reinforcement with a cross-section of 1 cm;

- to increase stability, the masonry of chimneys and ventilation risers is reinforced every three rows (cell 150x150), using reinforcement with a cross-section of 6 mm A1.

Everyone is dressed in wallpaper with nature themes! In front of the fireplace with decorative items! Detail to the next glass door firewood! Fireplace with wood panel and white stones next door! Lighting detail under the fireplace near the floor! Detail of the painting above and the red table, leaving a modern environment! How about a fireplace in the room?

All wood veneers and parts are from the three washers above! Look at the entire stone fireplace! All dressed in marble, wallpaper or porcelain tiles! All are lined with burnt cement! Fireplace clad in stone with two washers next to it! Like gas fireplaces, there are also ethanol fireplaces. It does not produce soot or sparks, but has the disadvantage of having a manual power supply. This has the advantage that it is portable, accompanying you in any room of the house. There are those that are made of stones, tempered glass and stainless steel.

Disadvantages of brick chimneys and methods of dealing with them

Speaking about the disadvantages of this type of chimney, it should be noted their relatively short service life - from 7 to 10 years. Large temperature changes in winter lead to the formation of condensation on them. Freezing and thawing, it eventually leads to the destruction of the brickwork.

Wood-burning fireplace with reforestation and glass dome. Its fuel is an ethanol-based biological fluid. It heats up to an area of up to 10 m². No installation required, just place it where you want. The model is equipped with a burner with a capacity of 350 ml of biofluid. Simply fill the container and light it with the included lighter. Another tool safely clears the flame. The amount of fuel consumed is sufficient for two to three hours of combustion, depending on the ventilation in the environment.

Organization of penetrations through interfloor ceilings and roofs

Because of the alcohol, the biofluid carries in its formula some components that help produce a yellowish and long-lasting flame and are unique to use in the brand's fireplaces. Matching wood splitter and glass items to match the fireplace! Heating must be compatible with the size of the environment and the average number of people who visit it. However, the final temperature is determined by the amount of wood burned, as well as the correct conduction and launch of the flue gas outside the flue gases released during combustion.

Reduce it negative impact You can use one of the suggested methods:

- increasing the cross-section of the outer walls of the chimney to 25 cm in areas where they protrude above the roof;

- insulating these parts of the chimney with a mineral slab.

Pipes for fireplaces will last longer if they are protected from the effects of precipitation using various types caps.

Significant disadvantages of this type of chimney include the presence of roughness on the inner surface, which significantly reduces the draft efficiency, in contrast to smooth chimneys.

To avoid this drawback, when designing a building, a chimney should be provided that provides a certain cross-sectional reserve.

You can increase the service life of a brick chimney by using galvanized steel pipes, installing them inside it.

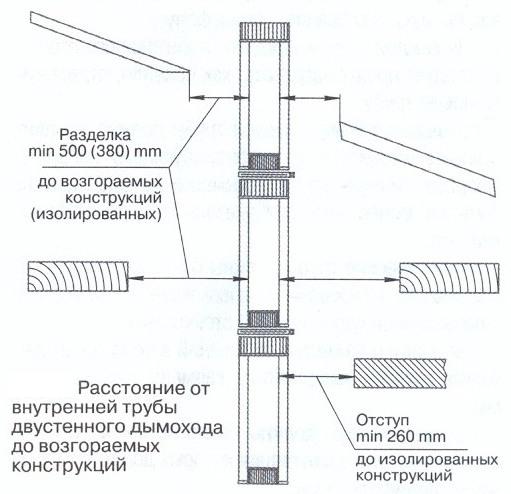

Fire safety requirements for chimneys

When carrying out work on chimney installations, do not forget about fire safety requirements:

- the distance from the wooden roof elements to the internal surfaces of the chimney must exceed 25 cm;

- wooden elements must be insulated with felt soaked in a clay solution or with two layers of asbestos cardboard.

Fireplace chimneys made of stainless galvanized steel

Such fireplace chimneys are assembled elements made of stainless steel, the thermal insulation of which is provided by non-combustible materials.

Similar ones are produced in various lengths and diameters, often complete with ceramic ones, which are located inside steel ones.

Steel chimneys have a number of advantages:

- they can be used without a foundation, as they are light in weight;

- their installation can be carried out upon completion construction work;

- they are cheaper than ceramic and block chimneys;

- In them, if necessary, you can easily replace individual structural elements.

The disadvantage of steel chimneys is that their use requires additional design solutions in the interior design of the room.

Ceramic block chimneys

Design features

They use lightweight concrete blocks as the basis for ventilation ducts. Manufacturers today offer a large selection of them, allowing you to choose the right size and height.

Vertical reinforcement is used to connect the blocks. A ceramic pipe and thermal insulation made of non-combustible materials are placed inside them. Depending on the manufacturer, during installation one or another technology may be used, tied specifically to the sample being produced. Application general rules would be unjustified.

Advantages and disadvantages of ceramic fireplace chimneys

Their advantages include:

- possibility of quick installation and assembly;

- ensuring high efficiency;

- long service life;

- the presence of a wide variety of blocks to create the desired configuration of chimney openings;

- the ability to clean the chimney due to the presence of an appropriate hole;

- the presence of a hole in the bottom of the chimney that allows condensate to drain.

The disadvantages of such systems include:

- relatively high cost;

- long delivery times (since these types of chimneys are mostly imported).

Even taking into account the shortcomings, ceramic fireplace pipes, in terms of their performance, are undeniable leaders among other types considered.

How to choose a chimney pipe

How to choose the cross-section of a chimney pipe

The choice of chimney cross-section depends on the size and type of boiler or fireplace. It is carried out adhering to the parameters: 140x140, 140x270, 270x270 (values that are multiples of the dimensions of the brickwork). Moreover, its diameter cannot be less than the boiler outlet diameter. The dimensions of the boiler outlet opening are determined by its type and power.

An exhaust vent is also planned in the immediate vicinity of the chimney. In accordance with SNIP, boiler rooms require an exhaust hood that provides 3 air changes per hour. For living rooms equipped with fireplaces, a hood providing 2-fold air exchange will be sufficient.

A rational decision would be one in which chimney will be surrounded by ventilation ducts. In this case, the size of, for example, a brick riser increases, and accordingly, the time of heat transfer from the brick to the room will also increase, and on all floors.

Other selection criteria

When choosing a fireplace or stove pipe, the type of fuel used is taken into account: liquid or gaseous requires a pipe wall thickness of 0.6 mm. When using firewood or coal, they must have walls 1 mm thick.

If the chimney is installed inside a brick shaft, then single-wall elements are used. If it is located separately in the house or outside, it is imperative to use insulating materials that will ensure the proper level of fire safety.

When choosing insulation thickness, consider the following:

- properties of the fuel used;

- properties of the material (combustible/non-flammable) located in the immediate vicinity of the chimney.

When using coal in wooden house chimneys with insulation of 50 to 100 mm are required.

If gas or diesel fuel is used as fuel in the fireplace, then the insulation of gas ducts can be 25 mm thick. In this case, it does not depend on whether there are flammable materials nearby.

To remove ash, a hole must be provided at the base of the smoke duct, closed hermetically with a door.

When purchasing elements for ceramic or steel chimneys, carefully check the permissible temperature limits.

If the fireplace is intended to be used solid fuel(firewood, coal), then pipes designed for a permissible combustion temperature of products up to 250 ° C cannot be used here; their purpose is gas or oil stoves.

It is also necessary to check whether the chimney has the required permits, whether it can be used in stoves operating on solid fuels, and what is its resistance to ash combustion at temperatures close to 1000°C.

When arranging pipes for a fireplace, remember that it should look like a vertical, homogeneous structure. Focus on the working height of the chimney 4 - 7 m and the optimal draft of 10 - 20 Pa. The rules for operating fireplaces require regular cleaning of chimneys and inspection by chimney sweeps 4 times throughout the year.

At the same time, compliance with safety measures when installing and using the device should be paramount.

Evidence of falsification of Russian history discovered

Evidence of falsification of Russian history discovered How they live in a monastery: confession of a nun

How they live in a monastery: confession of a nun Hatred towards Putin and his insane corruption is brewing in Russia

Hatred towards Putin and his insane corruption is brewing in Russia