25 storey building interior brick exterior wall. About the minimum thickness of load-bearing brick walls

- Brick walls and their minimum thickness

- Laying the first rows of a brick load-bearing wall

- Laying a wall with 1 brick

- Alternation methods for laying and size of seams

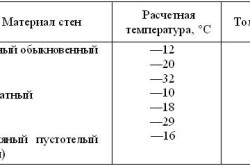

- Calculation of wall thickness taking into account thermal conductivity

- The influence of additives in masonry mortar on wall thickness

The construction of modern country and cottage buildings is subject to high requirements in terms of protection against heat loss. External ones must have excellent load-bearing capabilities. Calculation of the thickness of brick walls must be clearly coordinated with all the requirements for the construction process.

Thickness brick walls depends on the strength characteristics of the materials used and the properties of the insulation used.

Making the appropriate calculation, taking into account the coordination of the thickness of the wall and its reliability with standard brick parameters, we can come to the conclusion that the wall should have a width of about 3 m. The misunderstanding is as follows: a brick with the property of thermal resistance will not provide high load-bearing capacity to the walls.

Brick walls and their minimum thickness

There are no universal materials on the construction market that meet all requirements in any area. For certain conditions, a certain wall thickness is suitable. The typical dimensions of the most common types of bricks are 250*120*65 mm, they are standard.

The thickness of the load-bearing brick wall is calculated, taking into account the standard brick parameters of 25 cm. The requirements for the choice of wall thickness are often determined by the loads on it, since the frame of any building is a system load-bearing walls, which must be safe and reliable.

The load on load-bearing walls usually includes more than just their weight. It also includes the weight of other elements, which are partitions, ceilings, roofs, etc. The construction of buildings from materials requires additional reserves.

The minimum thickness of load-bearing brick walls should be less than 1 brick with a standard thickness of 25 cm, which is necessary to ensure normal heat-saving qualities.

Return to contents

Laying the first rows of a brick load-bearing wall

If the brickwork is made of the appropriate length, then the building will have a long service life. The required thickness of external load-bearing walls or internal ones is half a brick, or 12 cm.

To obtain an even masonry, it is necessary to prepare high-quality cement mortar. Composite external walls deserve special attention; they contain several different layers. These layers serve to ensure the safety of the structure, which is accompanied by conservation of thermal resistance. A combined external wall includes the presence of:

- heat insulators, which are foam plastic or mineral wool;

- materials, which are special panels, bricks for cladding, including plaster for the external decoration of the walls of the building.

The thickness of the walls is taken into account depending on factors related to temperature during the cold period, the type of heat insulator. The main function of thermal protection of walls belongs to the heat insulator, and its layer volume will change the thickness of the external wall. The masonry is kept to a minimum, but with the use of modern heat insulators, a high level of the result obtained is guaranteed. Certain types of bricks, lightweight concrete stones, and small-sized concrete blocks that have a solid structure or have vertical voids are used. The mass of these building materials is much greater than that of a simple brick. For example, their size is 88 mm, 140 mm or 188 mm, which ensures the connection of individual horizontally matching rows and seams with brick cladding.

If you use high-strength solid brick, then in terms of heat-shielding characteristics it is less convenient for masonry than multi-hole and thermal bricks. It has the greatest porosity, weighing from 1100 to 1300 kg/m³. They use grades of brick from M50 to M150, and grades of lime or cement mixtures, that is, binders, from 10 to 25. Masonry is carried out using special mixtures with a density of more than 1500 kg/m³. They are called cool mixtures and include cement-lime, sand, and light ones.

Solid masonry of solid brick walls with a width of more than 38 cm is not considered a way out. After all, a brick of these sizes, that is, its large mass, can make masonry less economical. This thickness of the outer wall, assigned according to thermal engineering calculations, can be considered excessive. Its load-bearing capacity is only 1/4 useful; for this reason, the construction of cottages is carried out on the basis of light types of brick. The use of appropriate heterogeneous wall masonry systems of layered or lightweight type involves the use of lightweight concrete stones.

Return to contents

Laying a wall with 1 brick

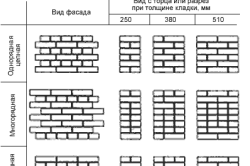

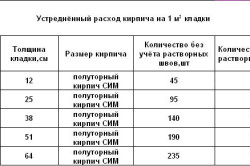

Average brick consumption per 1m2.

The thickness of a wall of 1 brick is equivalent to 25 cm. The bricks are laid side by side, but this does not affect the safety and strength of the wall. The main role in the quality of the masonry is played by the mortar used, which will not lead to jamming of the bricks. The minimum wall thickness, that is, 25 cm, is quite common. Depending on external influences and the load on the walls, the thickness is sometimes 1.5, 2 and 2.5 bricks.

The basic rule of masonry is the use of high-quality dressing of each vertical seam. The use of vertical joints must necessarily be accompanied by an overlap with the top row of bricks. By ligating, you can not only increase the strength of load-bearing walls, but also moderate the distribution of loads that arise.

There are various types dressings for seams: vertical; transverse, preventing shear brickwork etc. For example, longitudinal ones do not allow the wall to delaminate vertically, which prevents shifts in the horizontal type of masonry, and contributes to a moderate distribution of load along the load-bearing walls.

A wall of 1 brick is often laid according to the chosen system. For example, a single-row system involves laying the 1st row with the tongue side on the outside, and the next row is laid with the butt side of the brick outward. So, if the entire seam running across the masonry is displaced by 1/2 of a brick, then each longitudinal seam is displaced by 1/2 of a brick.

Return to contents

Alternation methods for laying and size of seams

Options for masonry with cladding.

A number of alternation methods are used when laying. If a single brick is used, then usually choose ligation using the butt method, which is carried out after every 6th row. When using a thicker type of brick, the number of spoon rows is minimized to 5. This type of connection is due to the high strength of the structure, which contributes to a moderate distribution of the entire load.

The thickness of the walls is 1.5 bricks made by laying from the corners, and the laying of the 1st row must be done at right angles with bricks, the thickness of which is 38 cm. It is convenient to control the correctness of the laying of the rows with a construction corner.

The 1st row is laid using a cord stretched over the entire height between the 1st and 2nd bricks. The interlocking surface of the bricks is made facing the outer side of the wall, and the masonry of the 1st row is oriented towards the inner side and the interfacing part inward. Laying the next row is carried out in the reverse order. This is how a mirror type of reflection of the masonry may appear in the 1st row.

As a result, the inner side of the walls is laid in 1, and the outer side in half a brick. Masonry of 1.5 is widely used, which occurs due to the reliability of the walls due to their high strength. The vertical seams do not coincide; they are overlapped by a solid part of the next row of masonry.

If an increase in the size of the seams is associated with the appearance of a deviation from the vertical plane or from the chosen direction of the masonry, then its method also changes. When constructing structures in areas characterized by severe frosts, the use of thermal insulators will make it possible to create a load-bearing wall of 2 bricks, which will be the most suitable option.

Return to contents

Calculation of wall thickness taking into account thermal conductivity

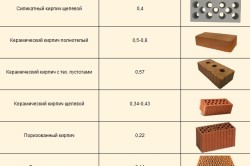

The thickness of the walls is often indicated in the construction plan; it is calculated taking into account all the reasons that influence the operation of the building in the future. The wall thickness should be calculated for the entire building. The purpose of the calculation is to develop a durable and comfortable structure. When calculating wall thickness, a special formula for determining thermal conductivity is used, which is written as R = S/k, where:

- S – material thickness, m;

- k – thermal conductivity coefficient;

- R is the thermal resistance of the walls of buildings erected in a certain region.

The value of the coefficient k depends on the region of future development. For example, k is equal to 3-3.2 for the Leningrad and Moscow regions, and for Yakutia and neighboring regions, which are republics of the Far North, k = 4.89.

Any building material has a thermal conductivity index. The thermal conductivity of a single brick is 0.58 W/m°C, which meets the standards. The thickness of the walls cannot be less than 250 mm including the heat insulator. Taking into account the thermal conductivity of bricks will help in the future to avoid excessive energy costs for heating the premises of the building.

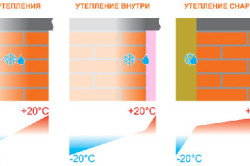

The method, which involves continuous masonry during construction, is economical even if there is external or internal insulation. The thickness of the external walls depends on the strength requirements for the structure.

If there is an internal layer of insulation, it is necessary to prevent the occurrence of condensation. This will require a vapor barrier. If there are external layers of thermal insulation, plastering of the surface will be required.

The greatest load requires reinforcement of partitions, piers and support pillars using an iron wire network with a diameter of 3-6 mm in height every 3 or 5 rows. Partitions are usually laid out in half-bricks 12 cm wide. The cross-sectional dimensions of the pillars should be 25 cm by 38 cm or more. Sometimes the thickness of the partitions can be 6.5 cm, and the method is called “brick on edge”. If the length of the partitions is more than 1.5 m, which are made using this method, the structure of the partitions should be reinforced with rods every 2 rows.

The brick surface of the walls is characterized by the greatest thermal inertia, which requires a sufficient amount of time for the wall to fully warm up. At minimum thickness brick wall, its mass is the greatest, and the process of cooling or warming up the wall will be lengthy. Thanks to these properties of the brick, the temperature level in the room will be constant throughout the day, which is a fundamental advantage. High level The thermal inertia of walls is often not favorable.

For example, in the cool season, operating country houses is a problematic task due to dampness in them. If the walls are frozen in winter, then this requires basic and additional heating, and temperature changes in the building are associated with the formation of condensation. For this reason, the minimum wall thickness requires additional cladding using boards.

Brick is one of the most ancient inventions of mankind. Water, sun and clay combined with the enthusiasm of the first craftsmen created artificial stone amazing strength, reliability and durability.

Such brick structures as the Moscow Kremlin, the Winter and Smolny palaces, and the Peter and Paul Fortress have survived more than one century. But their share included hard times of war, frosts, floods and fires. But to this day there is no need to restore their brickwork.

Today, when the market is overflowing with construction miracles, brick is still in fashion, it is still the number one building material. Its excellent load-bearing capacity allows the walls to withstand heavy loads created by concrete, reinforced concrete, and wooden floors of multi-story structures.

At the same time, brick is inferior to many wall materials in terms of heat and sound insulation qualities. For example, when it is -30 ° outside the window (and in Russia this happens quite often), the thickness of the external walls made of solid brick should be 64 cm. Whereas under the same climatic conditions, the sufficient thickness of the cobblestone walls is 18 cm.

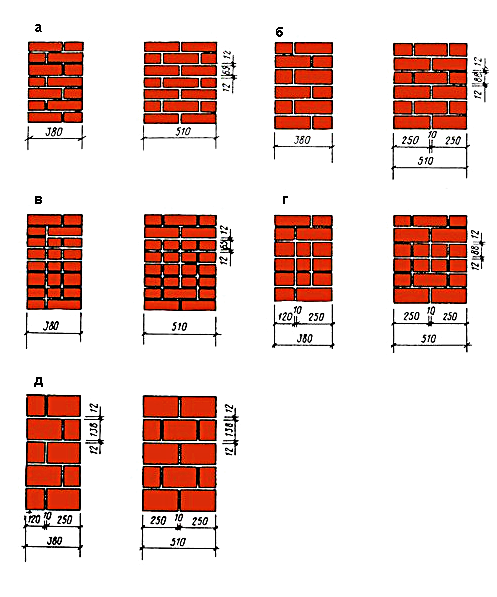

As you know, the thickness of brickwork is measured by the number of bricks laid along the thickness of the wall, and is a multiple of the standard brick parameters (6.5 x 12 x 25). Masonry of 12 cm is usually called masonry of half a brick, 25 cm - one brick, 38 cm - one and a half bricks, 51 cm - two bricks, 64 cm - two and a half.

However, thickening brick walls significantly increases the load on the base of the building, which inevitably affects the construction budget. How to increase the thermal conductivity and insulating qualities of brickwork without resorting to excessive weighting? How thick should a brick wall be? Experts say that its choice depends on the purpose and location of the wall.

Internal partition of the building

However, this is not enough for good sound insulation. To prevent extraneous sounds from entering the house, you should resort to one of three methods:

- increase the thickness of the masonry;

- apply additional material with sound-absorbing properties;

- use “on edge” masonry, when the brick is laid on its edge, which achieves a wall thickness of approximately 7 cm. If the length of a thin partition exceeds one and a half meters, it should be reinforced with reinforced wire.

Internal load-bearing wall

The thickness of the internal load-bearing wall of the house is 25 cm, or one solid brick, and can withstand any load from the roof, ceilings and other structures. An exception to this rule is a brick wall on which floor slabs are joined. In this case, single-brick masonry is unlikely to be sufficient.

External load-bearing wall

With a mission to carry outer wall 25 cm thick will cope completely. However, solid brick cannot cope with heat retention without additional insulation. Otherwise, in winter, at low subzero temperatures, the walls will begin to get wet.

Increasing the wall thickness to 64 cm, as already mentioned, is expensive in all respects.

The situation can be optimized by using hollow bricks in the masonry. Masonry should be carried out with the formation of wells, voids and widened seams. In this case, the thickness of the brick wall will be reduced to 51 cm due to voids. With their help, its thermal conductivity properties will also decrease somewhat.

The situation can be optimized by using hollow bricks in the masonry. Masonry should be carried out with the formation of wells, voids and widened seams. In this case, the thickness of the brick wall will be reduced to 51 cm due to voids. With their help, its thermal conductivity properties will also decrease somewhat.

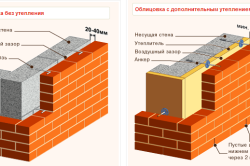

To achieve 100% thermal insulation, you cannot do without in-wall insulation. It should be borne in mind that experts do not recommend insulating a brick wall from the inside of the room. This is done either outside or inside the wall.

The recommended brick wall thickness in this case and the type of insulation depend on the region of residence. The outer wall can be insulated with a lightweight concrete mixture, expanded clay, expanded polystyrene, or slag. In addition to effective insulation, warm solutions should be used - both masonry and plaster.

The result is a dense “three-layer cake”, where:

- layer no. 1- the outer part of the wall is half a brick thick, that is, 12 cm;

- layer No. 2- insulation of the appropriate type and thickness;

- layer No. 3- the inner part of the wall is made of blocks or bricks 25 cm thick (to ensure load-bearing capacity).

This method of building a brick wall has three benefits:

- reduction of material costs;

- reducing pressure on the foundation;

- expanding the living space by reducing the thickness of the walls.

Building facade

Insulating the façade will also help improve the insulation and thermal performance of a brick building. This can be achieved in the following ways:

- conventional insulation of the facade, followed by its cladding or plastering;

- arrangement of a ventilated facade using siding, lumber, thermal insulation panels, plaster, facing bricks.

By listening to the advice of experts, you will build a brick house for your neighbors and yourself to enjoy. It won't resemble a massive pile of bricks. But at the same time it will become a reliable fortress for you - warm, quiet, cozy. It will be possible to live in this fortress house without bothering for several decades or even longer.

Brick is a durable, reliable building material with excellent load-bearing capacity. A wall, built in construction terminology “in one brick,” flawlessly holds almost any load. Support it on a supporting structure whose capacity is 25 cm, you can use reinforced concrete, wood and concrete floors, build several floors on top.

The reason for the thickening of brick walls is only to increase the thermal and insulating qualities of the house, which is associated both with the location of the residential building near airports, noisy highways, factories, and with the climatic specifics of the region.

Quite high thermal conductivity of brick and inertness in terms of maintaining the existing temperature dictates the application different options increasing the insulation of the building. To create a comfortable environment in a wooden house, a structure is enough load-bearing structures with a thickness of 20 cm, and the thickness of the brick walls to form equivalent indicators should be 64 cm. At the same time, heavy brick significantly increases the load on the foundation, and at the same time the construction budget increases. After all, the construction of the foundation often accounts for a third of all construction costs.

Ways to improve heating technology and insulation of brick buildings

Increased thickness of the brick wall, laying load-bearing structures “in two bricks”. The standard dimensions of the elements allow the construction to be made with a thickness of 51 cm, taking into account the thickness of the seam. Construction of brick walls with an internal air cushion. This is the name of the technology of well masonry, consisting of two walls of one brick and an empty space between them. During the construction of walls, it is filled with expanded clay, organic insulation, expanded polystyrene, slag, and lightweight concrete mixtures. Due to the presence of the cavity, the weight of the structure is reduced and insulation is increased.

Construction of a ventilated facade using lumber, siding, special heat-insulating panels, facing bricks, plaster.

Simple insulation of the facade followed by cladding or applying plaster.

Equipping brick walls with insulation from the inside. The insulation layer must be covered with a vapor barrier layer, then interior finishing must be done.

Read also: Installation of a concrete floor on the ground

For internal or facade insulation, the thickness of the load-bearing wall can be 25 cm, 38-39 cm when laying one and a half bricks, 51 or 48 cm. The discrepancy of 1-2 cm is due to the presence of a centimeter layer of binder material located between the brickwork elements. Load-bearing walls inside the building should not be thinner than the walls of 25 cm.

Thickness of internal partitions

Most often, in order to reduce costs and reduce the load, internal partitions are constructed from special foam concrete blocks. If the owners nevertheless gave preference to brick, then it is worth taking into account its standard dimensions. To build partitions, use a quarter or half of a brick. The thickness can be 12 cm, when laying elements on an edge 6.5 cm. It is advisable to equip thin brick partitions with a length of more than 1.5 m with reinforced wire.

Screw piles for a frame house: features and...

How thick should a brick wall be?

Brick has been used for building construction for hundreds of years. And even despite the abundance of other materials, it does not lose its relevance among consumers to this day. And all thanks to the strength that is inherent in this material - during further operation, the wall will be able to withstand almost any load in the form of a roof, floors and ceilings. And it is precisely the thickness of the walls of a brick house that mainly affects the load-bearing capacity of the entire structure as a whole.

Brick, compared to some other materials, has a number of undeniable advantages. These include: rather low thermal conductivity, frost resistance, bending and deformation strength, durability, sound insulation. But all these properties can be lost if the brick wall does not have the width required for specific conditions.

Let's consider how thick a brick wall should be according to established standards.

Standard brickwork thicknesses

Whatever type of brick is used to construct the structure, determining the thickness of the wall is quite simple. According to established standards, this parameter must be a multiple of half its length, i.e. 12 cm.

But brick blocks, produced today in factories, can be of different sizes. In addition, builders, when working with material, use various masonry schemes. This means that the walls will ultimately vary in width. Here is a table showing the thickness of a brick wall according to SNIP II-22-81, depending on the number of bricks used and the type of masonry:

Using the table, you can easily determine exactly what thickness the masonry has according to a particular pattern. For example, a wall laid with 1.5 bricks has a width of 38 cm, and with 2.5 bricks – 64 cm. And small discrepancies in the numbers from those indicators that should be a multiple of 12 are due to the fact that there is a concrete layer between several layers of building blocks. cement layer.

But there is also a minimum wall thickness in brick house, established by modern standards for stone and reinforced masonry structures - for a building height of up to 3 floors, the width of the brickwork must be at least 120-150 mm.

Standard brick wall thickness

What wall thickness is the most economically feasible?

According to many professional builders, a brick wall width of more than 38 cm is not economically feasible. Brick itself is a very durable material, and therefore to strengthen the structure and improve it thermal insulation properties It is sometimes more profitable to use some other additional measures than to increase the thickness of the wall. A heavy structure will only increase the load on the foundation. As a result, it turns out that the construction budget will increase significantly, since the foundation of the building will have to be strengthened.

A wall thickness of 2 bricks or more turns out to be quite large, so this masonry scheme is used mainly in the construction of large industrial facilities, where it is extremely important to give the structure maximum strength.

And to improve heat engineering and insulation brick buildings, the following methods are used today:

- Installation of a ventilated facade using siding, lumber or special panels.

- Insulation of walls using simple facing materials or applying a layer of plaster.

- To reduce the cost of building an individual house, lightweight block masonry is often used - like a well. This involves erecting 2 walls at a short distance from each other. In this case, the thickness of a half-brick wall is 12 cm, and the layer between 2 such walls will serve as a heat insulator. The diaphragms between the structures provide the building with the strength required by standards. The resulting cavity is filled with a certain heat insulator, for example, expanded clay or foam concrete.

- Insulation of the inside of the wall with heat-insulating material. In this case, the insulation must be covered with a vapor barrier layer.

Thickness of internal brick walls

Partitions inside the structure are designed to divide the entire area into separate rooms, sound and heat insulate the rooms. The optimal thickness of internal brick walls is 12 cm, i.e. here, as a rule, half-brick masonry is used. Walls of this size are quite enough for comfortable living here.

It is not uncommon practice for brick blocks to be laid “on edge”. This way you can get a whiter, thinner partition - 6.5 cm. At the same time, you can save a little on consumables. True, the heat and sound insulation of the rooms will leave much better.

To reduce mechanical loads on a 12 cm wide wall, porous or hollow silicate blocks are usually used. In the future, the walls are additionally insulated to improve their technical characteristics.

Thickness of external brick walls

The minimum thickness of external brick walls, at which they will serve as a strong support and thermally insulate the interior, is 25 cm.

If you build a brick house with insufficient thickness of external wall structures, in winter at low temperatures the walls will begin to get wet. In this case, you will have to either additionally insulate the structure or thicken it. Both options involve extra financial costs.

Thickness of load-bearing brick walls

The purpose of load-bearing walls is to bear the entire weight of the roof, partitions and all upper floors. It is quite natural that they should be much stronger than other walls. The minimum thickness of a load-bearing brick wall is 38 cm.

Some internal partitions in a residential building are also load-bearing. IN in this case, laying 1 brick will be sufficient when the wall thickness is 25 cm. Such a structure will be able to withstand any loads from the roof and ceilings without deforming or cracking.

The only exception, when the internal load-bearing wall must be more than 25 cm, is the joining of floor slabs. Here, under the influence of external conditions, deformations will form that can lead to the collapse of the building.

How to calculate material consumption when constructing brick walls of various thicknesses?

The first question that the designer of a construction project decides is what is the optimal thickness of a brick wall needed in a particular case. When choosing a suitable masonry option, the specialist takes into account:

- Type, brand and size of brick.

- Weather conditions of the region.

- Loads that will fall on the walls.

The permissible wall thickness in a building erected in a cold region is 25 cm. This is a wall thickness of 1 brick. But without using an additional layer of insulation, the width of the outer wall will have to be increased to 38 or 51 cm.

Standard dimensions of ordinary bricks: length – 250 mm, width – 120 mm, height – 65 mm. We will carry out calculations using the example of a building with walls of 4 m and 3 m, a height of 3 m. The standard thickness of walls in a brick house will be 25 cm.

Knowing the basic geometric dimensions of the walls, let’s first calculate the total area of the surfaces to be built:

4*3+3*3+4*3+3*3=42 m 2

Now let’s find the area of 1 brick block. Since we are laying 1 brick, this parameter is calculated by multiplying the width by the height of the block:

0.12*0.065 = 0.0078 m2.

To determine the amount of material for the construction of walls, their total area must be divided by the area of 1 block and multiplied by the number of masonry:

42/0.0078*1≈5385 pcs.

Knowing that the weight of 1 m 3 of brick is about 1800 kg, you can easily calculate the number of bricks that will be required for the construction of a specific construction project:

5385/1800≈3 m3

So, the thickness of a brick wall according to GOST, depending on the climatic conditions of the region and the type of building, can be different. But having a drawing prepared by specialists with the main dimensions of the walls and a masonry diagram, you can calculate the consumption of the main material yourself. This will help significantly save costs during the work process, since you can immediately purchase brick blocks in the required quantity, avoiding excess material.

V.V. Gabrusenko

Design standards (SNiP II-22-81) allow the minimum thickness of load-bearing stone walls for group I masonry to be taken in the range from 1/20 to 1/25 of the floor height. With a floor height of up to 5 m, a brick wall with a thickness of only 250 mm (1 brick) fits well into these restrictions, which is what designers are using - especially often recently.

From the point of view of formal requirements, designers act on a completely legal basis and vigorously resist when someone tries to interfere with their intentions.

Meanwhile, thin walls react most strongly to all kinds of deviations from design characteristics. Moreover, even those that are officially permitted by the Standards for the Production and Acceptance of Work (SNiP 3.03.01-87). These include: deviations of walls by displacement of axes (10 mm), by thickness (15 mm), by deviation of one floor from the vertical (10 mm), by displacement of floor slab supports in plan (6...8 mm), etc.

Let us consider what these deviations lead to using the example of an internal wall 3.5 m high and 250 mm thick made of grade 100 brick on grade 75 mortar, bearing a design load from the floor of 10 kPa (slabs with a span of 6 m on both sides) and the weight of the overlying walls . The wall is designed for central compression. Its calculated load-bearing capacity, determined according to SNiP II-22-81, is 309 kN/m.

Let's assume that the lower wall is offset from the axis by 10 mm to the left, and the upper wall is offset by 10 mm to the right (figure). In addition, the floor slabs are shifted 6 mm to the right of the axis. That is, the load from the floor N 1= 60 kN/m is applied with an eccentricity of 16 mm, and the load is from the overlying wall N 2- with an eccentricity of 20 mm, then the eccentricity of the resultant will be 19 mm. With such an eccentricity, the load-bearing capacity of the wall will decrease to 264 kN/m, i.e. by 15%. And this is in the presence of only two deviations and provided that the deviations do not exceed the values permissible by the Standards.

If we add here the asymmetrical loading of the floors with a temporary load (on the right more than on the left) and the “tolerances” that builders allow themselves - thickening of horizontal seams, traditionally poor filling of vertical seams, poor-quality dressing, curvature or slope of the surface, “rejuvenation” of the solution, excessive the use of half, etc., etc., then the load-bearing capacity can decrease by at least 20...30%. As a result, the wall overload will exceed 50...60%, beyond which the irreversible process of destruction begins. This process does not always appear immediately, but sometimes years after the completion of construction. Moreover, it must be borne in mind that the smaller the cross-section (thickness) of the elements, the stronger the negative impact of overloads, since as the thickness decreases, the possibility of stress redistribution within the cross-section due to plastic deformations of the masonry decreases.

If we add uneven deformations of the foundations (due to soaking of the soil), fraught with rotation of the base of the foundation, “hanging” of the external walls on the internal load-bearing walls, the formation of cracks and a decrease in stability, then we are talking not just about overload, but about a sudden collapse.

Proponents of thin walls might argue that all this requires too large a combination of defects and unfavorable deviations. Let us answer them: the overwhelming majority of accidents and disasters in construction occur precisely when several negative factors gather in one place and at one time - in this case there are no “too many” of them.

Conclusions

The thickness of the load-bearing walls must be at least 1.5 bricks (380 mm). Walls 1 brick thick (250 mm) can only be used for single-story buildings or the top floors of multi-story buildings.

This requirement should be included in the future Territorial Standards for the design of building structures and buildings, the need for the development of which is long overdue. In the meantime, we can only recommend that designers avoid using load-bearing walls with a thickness of less than 1.5 bricks.

Civil service in the navy

Civil service in the navy Why does an ex-boyfriend dream: the meaning of sleep in dream books

Why does an ex-boyfriend dream: the meaning of sleep in dream books Dream Interpretation: Why do you dream of a garden? I dreamed of a green garden

Dream Interpretation: Why do you dream of a garden? I dreamed of a green garden