Head on a pile-screw foundation. Leveling the plane of the pile-screw foundation and installing the caps. Construction of screw piles. Blade

One of the main requirements for the foundation is the creation of a single plane of supports relative to the lower foundation of the house. In case pile-screw foundation this is achieved by cutting the ends of the piles to the level and installing the caps. Pile heads are needed for reliable installation of foundation piping.

1. Trimming piles to level

The installation of screw piles ends with cutting them relative to a single plane. Obviously, it is almost impossible to achieve the same level when screwing in several piles, so after screwing they are cut so that the foundation plane is uniform. The plane is drawn out after all the piles have been wrapped.

Already when installing piles, you need to have an idea to what level the foundation will be raised and control the height of the end of the piles above the ground. After screwing is completed, one of the piles is selected, relative to which the height of the entire foundation plane will be selected.

It is cut perpendicular to the body of the pipe, and then all other piles are marked for cutting.

There are two main ways to derive the foundation plane:

- Using a water level

- Using a laser level

The first method is quite complicated and will require care and attention. The water level is a long transparent plastic tube filled with water. One end of the tube is brought to the reference pile so that the water level in the tube coincides with the cutting level of the pile.

Next, the tube is extended to the next pile and attached to it. The level to which the water in the tube has risen will correspond to the height of the reference pile relative to the horizon. A mark is made on the pile at which cutting will be done. The maximum deviation should be no more than 1-2 mm.

The cutting levels of all other piles are marked in the same way.

The next step will be cutting each pile itself. The optimal cutting method is using an angle grinder, the so-called “grinder”. The use of an abrasive cutting wheel makes the cut neat and even.

Before cutting the pipe, you need to make sure that the cutting plane is correct. To do this, it is best to use this technique. The pipe is wrapped in thick cardboard or similar material, so that the top edge coincides with the mark made on the pipe. Then a circle is drawn along the top edge of the cardboard with chalk or a metal marker. Before sawing off the pipe, it is recommended to make a preliminary cut along the entire circumference.

As a result of cutting the pipes, we get a set of even ends of screw piles above the ground surface. This will be the basis for forming the foundation piping.

After cutting all the pipes, it is recommended to double-check that they are level correctly. If an error occurs on any pipe, it must be taken into account in further work - mark the defective pipe and either trim it slightly, or later install an additional lining under the grillage - if the pipe is cut too low.

2. Functions of screw pile heads

There are several main types of tying a pile-screw foundation:

- Installation and fastening of support beams at the ends of pipes

- Connecting pipes with metal channels and beams to create a common frame

- Creation of a combined concrete grillage based on screw piles

The first type of piping is considered the most common when constructing a foundation for most buildings - from residential buildings to light outbuildings, such as a bathhouse, summer kitchen or veranda. This type of piping requires caps at the ends of the pipes.

3. Types of heads

Heads primarily differ in their shape:

- T-shaped

- U-shaped

T-shaped heads are more common. They are a piece of pipe with a platform welded to its end. The foundation framing beam is subsequently laid on this site.

U-shaped heads are usually used for laying beams that require stronger fastening to resist lateral loads. They seem to be inserted into a square socket and fixed on the side with fastening material.

According to the method of connection with the ends of the screw pile pipes, the ends are divided into

- Welded

- Removable

From the name it is clear that in the first case, the heads are tightly welded to the pipe body at the stage of pile manufacturing. This is a rare case, since usually the foundation plane is leveled by cutting the piles after installation at the general level, as described above. After trimming, the head is put on the end of the pipe.

According to the shape of the platform on which the trim beams are installed, the heads can be divided into:

- Square

- Round

- Polygonal

The shape of the heads is mainly determined by their purpose. In most cases, square sites are used in the construction of buildings. Round head platforms are most often used to attach single pillars to them - in this case, the platform most evenly takes on the load from the weight of the structure. Platforms of a different shape are placed depending on the shape of the base of the structure, if necessary.

Heads with a square platform are considered the most common in construction.

Head design in general view is a metal plate welded to a piece of pipe. The diameter of the pipe should be slightly larger than the diameter of the screw pile on which the head is attached. It is, as it were, put on the end of the pile, and thus the end of the pile is equipped with a kind of cap, which increases the diameter of the base of the foundation. They are shaped like an inverted glass. The dimensions of the heads are usually in the range of up to 150x150 to 200x200 mm and a little more for corner piles.

To impart structural strength, the heads are equipped with stiffening ribs. These are metal strips welded onto the bottom of the platform. Stiffening ribs (kerchiefs) can have a wide variety of shapes and the number per head - from 3 to 6..

4. Installation of heads

Installing pile heads consists of securing them to each support. Before installation, after trimming, the piles are cleaned of paint. You definitely need to check the level of the head. The site must be perfectly level relative to the horizon. Skewed heads can lead to uneven loads, skewed piping and, as a result, limit the durability of the entire foundation. If the platform does not fit horizontally, you should either check whether the pipe is cut correctly or the head itself. If there is a small defect, it is recommended to weld strong linings under one or another edge of the connection between the pipe and the head.

Checking the level of the site

Checking the level of the site

Before welding, the edge of the head is processed with a file to remove the paint layer. It is recommended to clean the inner wall of the “glass” of the head with an angle grinder along a pre-designated line about 20 cm wide. To do this, put a cleaning disk or brush on the “grinder”. The paint on the edge of the head is better removed with a cleaning disc.

The welding process is carried out using a standard welding machine using conventional standard 3 mm electrodes. Welding current is used within 90-100A.

Thus, the work procedure includes:

- Installation of the head

- Control of the horizontal plane of the site

- Tack spot welding of the head in two or three places

- Welding around the entire perimeter

- Painting of cleaned areas for anti-corrosion protection.

It should be noted that it is necessary to leave a seam section of 10-15 mm to ensure ventilation of the head. Otherwise (since the body of the pile itself is filled with concrete), moisture will inevitably condense from inside the head due to temperature changes. If there is no ventilation, this area will become a hotbed of increased corrosion.

After welding all the heads, the foundation plane will be checked again to ensure that it is level. If necessary, it is better to re-install the head or several heads in places where mistakes were made.

After all work is completed, the strapping bars can be installed on the heads. They are usually attached with bolts - for this purpose, corresponding holes are pre-drilled in the heads.

5. Conclusion

The role of caps in the stability of a pile-screw foundation is quite large. They ensure the stability of the strapping beams, the horizontality of the surface and reliable fastening of the strapping to the screw piles. Self-production heads is a difficult task in artisanal conditions. It is easier to purchase them complete with screw piles.

The world's population is growing exponentially every year. The housing issue is becoming more and more pressing for hundreds of families who want to have a house or apartment of the required size and, most importantly, in a “decent” location.

For cities with a population of one million, this is the most pressing issue. After all, there are fewer and fewer areas suitable for development, and more and more apartments are needed. Many developers have begun to use all available sites, regardless of geological features.

Thus, city authorities are willing to give up swampy lands, areas with groundwater, etc. for new construction. In order for houses to be built not only quickly, but also with high quality, developers often use piles for such cases.

What are piles?

Piles are supports made from various materials: metal, concrete, reinforced concrete structure, frame, soil or sheet piling. They are used to make the structure more stable and less susceptible to groundwater and foundation corrosion.

Depending on the structural characteristics of the soil on which the foundation is poured, the developer can use different ways installation of such supports. The main criterion is the weight of the entire building structure, as well as on which it will be built.

For this, a pile driver, a diesel hammer, a vibratory hammer, a hydraulic hammer and a pile pressing machine can be used. In special cases, when rocky layers are possible, a drill is used.

Pile heads

Even the most experienced master cannot install the piles in such a way that their upper part, which will hold the entire foundation, is at the same level. These supporting parts are called pile heads.

The shape of the head depends on the pile used for installation. It can be round, square, rectangular. In addition, for ease of installation of the base, various fastening methods can be used.

To pour the base for the foundation at the required level, the craftsman needs to install a frame (grillage) on the columns, which is secured with the help of caps.

Types and features

The pile heads differ not only in shape, which corresponds to the shape of the installed pile, but also in size. At the same time, do not forget that when using a screw or concrete pile, the tip will also be different.

An important nuance in choosing the head is its shape: it can be T-shaped or U-shaped. When installing a grillage on the head T-rev different shapes You can install both formwork and a slab for pouring the foundation.

Only beams can be used with U-shaped heads, and their diameter must match the width of the tip.

Dimensions

Screw and reinforced concrete piles have remained the most popular on the market for a long time. Their cost, reliability and long service life make them the most popular.

When choosing a material, the developer is guided not only by the characteristics of the soil, but also by the magnitude of the load in the form of the room being installed. Taking into account all the nuances, the design for installing the grillage is also selected.

The average size of the screw pile head in diameter, in its pipe part, ranges from 108 mm to 325 mm. And the diameter of the head itself can vary from 150 mm to 200 mm.

The smallest diameter tube is 57 mm. Such a base can withstand a load of eight hundred kilograms. Most often they are used for the construction of light outbuildings (garage, gazebo, barn).

Wider pile with a head diameter of 89 mm. Pillars with this diameter are used in peat or wetlands for the construction of dachas, bathhouses, garages, and fences.

Piles with a cap size of 108 mm are the most “hardy”. They can easily withstand a weight of three and a half tons, are mounted mechanically and are suitable for almost all types of soil.

The concrete pile head has square shape with sides ranging from twenty centimeters in length. The greater the load, the longer the reinforced concrete pile.

Screw or reinforced concrete?

The question of choosing material for piles remains open, primarily due to the size of the construction site. For industrial-scale orders (high-rise buildings, commercial and administrative buildings, bridges) reinforced concrete pillars are used.

They are durable, resistant to corrosion, and can withstand temperature changes well. The disadvantage of this type of piles is the high cost of installation. It is produced using special equipment.

Screw piles are less expensive to install. They can be installed using only human resources. Therefore, screw piles are most often used during construction country houses, small cottages.

Chip or cut?

In order for the structure to have a level foundation, after installation the piles are cut to the required level. The pile heads are cut down using:

Jackhammer (small amount of work);

Hydraulic pruning (construction of residential complexes or shopping centers).

To carry out all the necessary manipulations, the master marks the desired height at which the pile will be cut. And then, if it is a concrete structure, using improvised means, make a furrow and chip off excess concrete.

Only the metal frame is left, which is cut off using hydraulic shears and a jackhammer. If necessary, craftsmen can “tie” the remaining rods and foundation formwork.

This method of removing “excess” is quite labor-intensive and can take a lot of time. The craftsmen process no more than fifteen heads per shift.

More affordable and quick way- cut off the ends. This method is convenient and economical. Suitable for use with various types piles A big advantage is the high-speed processing of the ends, which significantly reduces the time for arranging the grillage.

For trimming, improvised cutting tools are used - a grinder, with an installed tape or disk circle; abrasive saw.

Before starting work, mark the cutting line with a marker or chalk, and make a furrow around the circumference for an even cut. If the tool or pile begins to heat up, they are cooled and only then work continues.

The disadvantage of this processing method is its complete unsuitability after cutting and the rapid wear of the working tool. Which may entail additional costs for the purchase of consumables.

How to properly prepare for assembly?

If metal piles were chosen for the foundation equipment, it is necessary to carry out preliminary work so that the pile heads last longer.

After trimming at a level of two or three centimeters from the cut site, you need to remove the coating layer that protects the material from exposure to factors environment. A metal brush or a special attachment on an angle grinder is perfect for this.

Installation

Installation of pile heads also has its own characteristics. The main criterion for installation is the type of pile and the material from which it is made. If a screw pile was used during construction, its heads will necessarily be metal and secured by welding.

This can be a T-shaped head in the form of a plate with a round base, which is placed on the pile and secured with a weld. In addition, if a channel or I-beam is used to install the grillage, they are welded to the end of the pile in a special way.

The I-beam is welded in the form of a square plate, and the channel is turned over with its “wings” down and welded to the base. If, according to the architect's idea, the building is erected from wooden beams, the first “line” of logs is connected to the head with a metal rod.

For welding work use electrodes with a size of 3 millimeters, the current value is no more than 100 amperes.

If a concrete pile cap is used to install the foundation of the grillage, its installation begins after cutting down the pile caps to the required level. Heads of this type are mounted in concrete mortar during pouring of the foundation into formwork installed on piles.

And now for the good stuff

The use of piles in construction is not new. But there is a possibility that not all customers have encountered their use in life. Many people are confused by the lengthy process of their installation, as well as the rather labor-intensive method of installing the grillage.

It is worth noting that the use of a foundation of this type saves home owners from many negative factors. This:

- Spring-autumn floods.

- Soil instability (peat bogs, swamps, quicksand, floating rocks).

- Ease of installation, independent of weather conditions (frost, heat, etc.).

- Construction of buildings on uneven surfaces;

- Distribution of weight load along the contour of the foundation.

There are a lot of projects in the world, in the construction of which foundations installed on screw and concrete piles were used. Most of them are eco-projects, the function of which is to preserve the pristine beauty of the places chosen for construction. The protected corners of Norway and Finland have been enriched with unusual buildings “on chicken legs”. They not only became cozy homes for their owners, but also an attraction for curious tourists.

Beautiful, comfortable, and most importantly, safe homes amaze with their simplicity and original design. What type of piles and caps will become the basis of your house is up to you to decide. The main thing is that this foundation will serve more than one generation of your family.

When constructing a foundation, screw piles are often used among other types of supports. The main advantage of this type of piles is their moderate cost. In addition, such supporting elements make it possible to adjust the height of the base of the entire structure and erect buildings in areas with heterogeneous terrain. At the final stage of foundation construction, caps are installed on the upper ends of the supporting structures.

Purpose

The building element called the head is a metal plate with a short pipe and stiffeners welded to it. The cap covers the upper end of the pile after it is buried. It is attached to the supporting element by welding or bolting.

The function of the caps is to become a support for subsequent levels of the superstructure and evenly distribute the load on the foundation from the entire structure. Construction slabs and beams will rest on the plane of the heads. They can also be used to fasten timber. In this regard, all supporting elements must be located at the same level relative to each other.

But in most cases, it is simply impossible to drive piles to exactly the same depth. To ensure a level plane for installing slabs and beams, the upper ends of the piles are cut flush with a single horizontal line.

Also, thanks to the installation of an end cap, the degree of damage to the pile by corrosion is significantly reduced.

Heads can be of different shapes and types depending on the type and configuration of piles used in the construction.

The end elements are made from high-strength structural steel. For additional protection, the heads are coated with alkyd-based primers.

Types of supporting elements:

- Screw. Such piles are metal pipes of various diameters with a screw base. When the metal support rotates, it sinks into the ground to the required depth. To secure the supporting element after deepening into the pipe cavity, concrete solution is poured. The diameter dimensions of such support structures vary from 108 mm to 325 mm.

- Bored or concrete base. Installation requires drilling through the soil. A frame made of reinforcement is placed in the recesses and concrete is poured.

Advantages of screw piles:

- hold the structure well during extensive floods;

- can be used for construction on unstable soils and heterogeneous terrain;

- installation of supporting elements can be carried out in any weather conditions, including frost;

- uniform distribution of the load from the entire structure, with the exception of foundation overloads and distortions;

- allow for controlled lifting of the structure above ground level.

Species

Heads for screw piles have a base in the form of a round short pipe of various diameters.

The end elements for piles primarily differ in the shape of the top plate. They can be U- and T-shaped.

U-shaped elements have brackets on their surface. They are mounted on piles for subsequent laying of beams or timber on them. Moreover, it is important to choose the width of the brackets that strictly matches the size of the beams.

The second type of head has a completely smooth surface. A tile grillage can also be laid on it.

The next parameter of pile caps is the diameter of the plate and tubular base. These dimensions depend on the diameter of the supporting elements installed at the base of the foundation of the structure being built.

The minimum diameter of the round pipe of the lower part of the head is 57 mm. The maximum load that can be placed on such a base is no more than 800 kg. Such thin piles are usually used for the construction of lightweight buildings and structures: garages, sheds, gazebos.

The most common in private construction are piles of medium size and strength. Their diameter is 89 mm. They are even used in peat and wetlands for the construction of country houses, bathhouses, fences, and garages.

The maximum size of the head base is 108 mm. It is mounted on a thick and durable support. Such structures can withstand a weight of up to 3.5 tons. They can be buried in any type of soil. They are used to construct supports for heavy buildings and structures, including bridges.

Head caps can also be welded or removable. The first type is attached to the base by welding. Removable end elements can be secured with bolts.

Pile adjustment

To give the supporting elements the same height, they are cut or trimmed. This process is somewhat labor-intensive and requires skill, but it can still be done with your own hands.

Stages of work:

- At the beginning, you should select a control support pile. It is its height that will need to be guided when correcting the length of other supporting elements.

- On the remaining supports, a marker is used to draw a line along which the pipe will be cut or trimmed. Horizontal consistency should be checked with a laser or hydraulic level.

- The ends of the support elements are cut off using a heavy jackhammer. The cutting line is first cleaned with a file. The blow is applied horizontally along the top edge of the pipe.

- You can use a grinder or an abrasive saw to cut the base pipes. The cut is made along the line marked with a marker, moving along the diameter of the base or towards the center of the pile.

- Another option for cutting the ends of piles is the use of hydraulic equipment. Renting it, let alone purchasing it, is not cheap. However, this method makes it possible to make a very even cut, without damaging or chipping the entire base.

Installation of ends:

- Prepared piles should be cleaned of paint using grinding equipment.

- The head is placed on the base. Using a level, check that it is horizontal.

- Preliminary welding of the element is carried out in 3-4 places by spot welding.

- Using a welding machine, the head is welded around the entire circumference. A small area of 5-10 cm should be left unwelded. It is necessary for the passage of air and ventilation inside the base pipe.

- The weld seam should be cleaned and paint or primer applied.

When building a private house, a very important step is laying the foundations. The choice of this design depends on the following factors:

- Depending on the type of building being built.

- Depending on the type of soil that lies on the land plot.

- Depending on the financial situation of the customer.

If the site where construction is planned has a complex, uneven topography, or heaving and waterlogged soils, then in this case it would be advisable to use a pile foundation.

When constructing a private building, the following types of piles can be used:

- Screw. They are metal pipes with a screw auger at the bottom. When such a pile rotates around its axis, it sinks into the ground. Afterwards, concrete is poured into them to the required level.

- Bored. This type is made of concrete. The soil is drilled with a special garden drill, a frame made of reinforcement is placed in the resulting holes, and concrete is poured. The walls of the pit act as formwork. For loose soils, various pipes can be used.

Head Features

Purpose

The head is the supporting part in the structure of the pile. After all the rods are installed, you need to install horizontal strapping on them. The rods are pipes, how do you put a base on them? This is exactly what the heads are needed for, which are placed on the rod pipe.

This design is a rectangular sheet of metal to which a pipe with stiffeners is welded. This pipe must be larger in diameter than the pile in order to fit freely on it. The plate around the perimeter has holes for fastening. After installation, a grillage is mounted on these elements.

The grillage can be based on the type of occurrence:

- Buried.

- Not buried.

- Suspended.

By type of materials used:

- Wooden.

- Made from metal profiles.

- Reinforced concrete.

Types

By type of head they are produced:

- With a round cross section.

- Rectangular section.

- Polygonal.

- In the form of a brand.

The form is:

- U-shaped.

- T-shaped.

By installation method:

- Welded. The heads are welded to the body of the pile. First, a connection occurs at three or four points, and then along a circle. An important feature is that the welding seam does not close, leaving a gap of approximately thirty millimeters.

- Bolted. Fastening occurs through a bolted connection. Hardware for fastening is best used with a galvanized coating.

According to strength characteristics:

- Standard.

- Reinforced.

The choice of this product depends on the specific construction conditions; they must be purchased taking into account the design load.

The main factors influencing the choice of this design:

- Grillage type and material.

- Types of piles used.

- Building design.

Installation features

Cutting

The cutting technology can be used for rods made of any material. Wood, metal and reinforced concrete can be cut. The only difference is in the tool used. When cutting wood, a regular saw will do.

For metal you will have to use an angle grinder. When cutting concrete, a special circle is put on this machine. You can also use circular saws with various cutting elements.

Cutting equipment can be:

- Manual.

- Machine tool.

The cutting procedure can be divided into the following stages:

- A line for cutting will be marked on the pipe. It is necessary to measure from different sides. When marking on one side, there is a danger of making an uneven cut. This will become clear at the stage of installing the head. During installation it will be very difficult to bring it into a horizontal position.

- Using a cutting tool, first saw a small furrow along the cut line.

- Next, along this furrow, the pipe is directly sawed off.

This technology has certain advantages:

- High productivity.

- Low cost of cutting tools.

- Easy to implement and does not require the involvement of qualified specialists.

Flaws:

- Rapid wear of cutting discs.

- This type of work is quite traumatic. Strict compliance with safety requirements is necessary.

Installation

After all the rods have been twisted to the design mark and cut to required level, installation of pile heads begins. We put this element on the rod and draw a mark to which it sits on the pipe.

After reaching a strong load-bearing layer, screwing in the pile stops. Now it needs to be cut and filled with concrete. The final installation of the pile foundation is securing the ends of the supports for screw piles to the cut ends. A frame made of a channel, timber or other plinth structure will be fixed to them. The shapes of the heads are different, the simplest is welded: in the form of a metal plate and a mounted ring with stiffeners.

Purpose of heads

The top end of the support is called the pile head. The grillage beam or slab rests on it. For this reason, all the heads of the pile part of the base must be located at the same level. If this condition is not met, the beams and grillage slabs will rest on the piles with a distortion, which will lead to a deterioration in the bearing capacity of the foundation.

In the photo - ready-to-install screw pile heads

In the photo - ready-to-install screw pile heads

Unfortunately, the process of installing piles does not require the heads to be positioned on the same line. When driving screw piles, this procedure is quite difficult, and during the driving process it is simply impossible to align the piles in the same plane. The solution is simple: after being buried in the ground, the supports are cut off or cut down to a level with the correct horizontal line.

The size of the head depends on the diameter of the pile body and specific gravity structure that fits onto the head slab. The internal diameter of the head pipe is slightly larger outer size piles to fit tightly, loosely and deeply on it. For significant loads on the grillage axis, reinforced caps are used. They are made of high-quality steel with four-sided gussets and coated with an anti-corrosion compound.

Layout of the screw pile head

Layout of the screw pile head

The caps are identical in size to the dimensions and cross-sectional contour of the pile. The shape of the heads is multivariate: round, square, tee, polygonal. The size of the top of the pile will depend on its type. For example, the dimensions of the head of a screw pile can be fit into a circle Ø 10.8 – 32.5 cm. Reinforced concrete piles are produced in the shape of a square with a side of 20 – 40 cm. Wooden piles can be fit into an irregular circle Ø 18 – 32 cm.

The head of the screw pile is a transitional part that connects the head of the concrete pile with the grillage parts. The type of head depends on the type of structure. A house made of aerated concrete can be built on a foundation made of screw piles without caps: the screwed piles are tied together with a channel and a reinforced concrete slab is laid on them. For a frame or timber house, the presence of caps is desirable. It is attached to the pile as a cover. Typically, such a head is fixed rigidly and does not require welding.

Head types

The head shape can be of two types: T-shaped and U-shaped. All of them are installed on the pile shaft after cutting or trimming its upper part. The installation technology of any version of the cap part depends on the type of pile. For example, the head of a screw pile is mounted by welding, and for a reinforced concrete pile it is installed by pouring it into formwork, which is mounted on top of the cut end.

The photo shows the process of making a head for a screw pile

The photo shows the process of making a head for a screw pile

A beam and slab grillage is mounted on a T-shaped head or on a smooth end. In this case, the supports are buried in the horizontal part of the foundation or support the beam and grillage slab. Only beams are laid on U-shaped heads with the condition that the width of the U-shaped bracket coincides with the thickness of the beam.

There are headers welded and removable. When installing supports manually, removable heads are used. They are also suitable for heavy soil. If the pile is screwed in only to the freezing depth, the remaining part of the pipe is cut off and the head is put on. Removable heads have a glass, 3-6 gussets and a square. Head dimensions: 150x150 or 200x200, for corner piles they can be larger - 150x300 or 200x400.

For piles that are screwed in with a hole drill, welded type heads are used. Their advantage is that when they are on top, water and oxygen do not get inside the support, so the pile is less susceptible to corrosion. Welded heads also have 3-6 gussets and a disk Ø 150, 200, 250 mm with 6 holes.

Features of installation of heads

Cutting down pile heads

In the photo - special equipment for cutting the head of a reinforced concrete pile

In the photo - special equipment for cutting the head of a reinforced concrete pile

The cutting of the heads is carried out after driving or pressing the piles. Remove the section of the reinforced concrete support that rises above the horizontal level of the grillage.

The size of the area to be removed is marked with a marker on the pile shaft. Determine the position of the marker using a level (hydraulic or laser) along the control support.

Standard equipment used for cutting piles is a hydraulic shear and a jackhammer. A manual jackhammer is a budget option due to its low cost. Hydraulic shears have higher cutting quality and cutting speed, but their cost is tens of thousands of rubles.

Algorithm for cutting with a jackhammer:

- A cutting line is marked on the piles.

- Using a hammer, make a furrow around the support along the marked line.

- With vertical strokes, pieces of concrete are removed from support, leaving only the reinforcing frame.

- At the last stage, the reinforcement can be cut off or connected to the grillage’s reinforcing frame.

Productivity with this technology is on average 12-15 supports per shift. It is also difficult to predict the quality of work, since a rough tool can destroy part of the support under the cut line.

Hydraulic shears work simpler: a ring-shaped nozzle is put on a support, focusing on the cutting line. Then the cutting edge of the scissors practically bites off the concrete part of the support without touching the reinforcement. The entire operation takes up to 10 minutes. The quality of the cut line is incomparable to the result of a hammer.

Cutting off pile heads

In the photo - cutting a screw pile with a circular saw

In the photo - cutting a screw pile with a circular saw

The head of the support can not only be chipped, but also cut off. The technology is suitable for all types of piles, because you can cut metal, reinforced concrete, and wood; you only change the cutting tool: disk, chain, milling cutter.

To cut the pile heads, a manual or machine cutting or abrasive tool is used. The standard cutter is a band saw or circular saw, the abrasive cutter is an angle grinder. The cutting technology does not depend on the type of tool.

- Mark the cut line on the supports with a marker.

- Turn on the grinder or abrasive wheel, maintaining the operating speed.

- A calibrating groove is drawn along the marked circle, and the tool is moved in a circle or in a straight line. Heating of the pile and cutting tool is prevented by the coolant.

This method is characterized by high productivity and relatively low cost of the tool. The downside is the impossibility of preserving the reinforcement: the frame is cut off along with the head. In addition, the cutting tool wears out quickly. The tape or disk is restored by updating the angles on the teeth, and the abrasive wheel is completely ground off. Using this technology, you need to plan the cost of replacing the cutting tool.

Installing the head on the pile

The installation of a foundation made of screw piles ends with the cap being secured to each support. Before starting welding work, the area is cleared of paint. The head is installed on the pile and the position is checked with a level. If the site is not laid strictly horizontally, the cause of the crooked fit must be eliminated.

The photo shows the prepared surface of a screw pile for installing the head

The photo shows the prepared surface of a screw pile for installing the head

Use a file to mark the edge of the head, removing the paint down to the metal layer. Cleaning is carried out with a grinder along the intended line 20-30mm wide. You can install a cleaning disc or cord brush on the grinder. The latter is enough to clean seams and paint on 20 piles. The paint is also removed from the edge of the head. A disk is more suitable for this.

Welding of the head is possible using an inverter converter. Electrodes use universal ones (3mm), welding current─ 90-100A.

In the photo - welding the head of a screw pile

In the photo - welding the head of a screw pile

Standard welding pattern:

- Installing the head in the correct position with control of the horizontal plane.

- Seizing the head in 2-3 places by spot welding.

- Welding the head around the entire perimeter, leaving a 10-20 mm seam section to ventilate the head inside.

At the last stage, the slag must be removed using a hammer and brush, and while the pile is still warm, the cleaned areas must be covered with paint. We get a durable protective coating.

Pile heads - purpose, design and installation

Pile heads - purpose, design and installation After reaching a strong load-bearing layer, screwing in the pile stops. Now it needs to be cut and filled with concrete. Final montage

B1 in English what level?

B1 in English what level? Managing verbs in German - German online - Start Deutsch

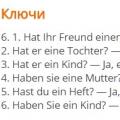

Managing verbs in German - German online - Start Deutsch Conjugation of the verb haben (to have) in the present tense

Conjugation of the verb haben (to have) in the present tense