Concrete lintels above windows in an aerated concrete wall. Window openings in aerated concrete

In an aerated concrete house, window and door openings need additional reinforcement. This can be in monolithic concrete, as well as on corners or reinforcing bars. They differ in cost, efficiency, and speed of installation. The exact parameters of the supporting area of the lintels, their length and width are calculated depending on the width of the window opening and the height of the masonry above it.

In houses made from a minimum pier width of 60 cm is provided. When the width is reduced, it is necessary to perform vertical reinforcement of the pier: reinforcement by pouring steel rods inside O-blocks or by placing rods in a vertical groove next to the opening, followed by fixing the reinforcement in the foundation and interfloor slabs.

Laying ready-made aerated concrete lintels

To strengthen openings, builders often use factory-made solutions, since it is easiest to make a lintel over a window made of aerated concrete from ready-made reinforced products. Ready-made lintels are used to cover openings up to 2.5 m wide.

The lintels are made from a steel reinforcement frame and aerated concrete grades D500-D700 with increased compressive strength. They can be made to order - for the specific parameters of the house being built.

Peculiarities

Advantages of ready-made aerated concrete lintels:

- high laying speed;

- absence of “cold bridges”;

- relatively light weight.

The smooth surface and clear shape of the product do not spoil the evenness of the wall, so for exterior finishing you can use facade paint or thin-layer plaster. A big plus is also the uniformity of the wall surface when it comes to plastering.

The lintels above the windows in a house made of aerated concrete are installed on whole blocks, resting on the masonry at least 25-30 cm on each side. Longitudinal voids are filled with adhesive or cement mortar. It is convenient when the thickness of the beam coincides with the thickness of the masonry, and the height with the height of the block. When building a house with thick walls, it is possible to lay several products. For example, for a wall with a thickness of 500 mm, you can purchase 2 beams with a thickness of 300 and 200 mm and lay them over one opening.

The correct position of aerated concrete lintels during installation is indicated by markings. It is unacceptable to fasten beams vertically or with the bottom up. It is also prohibited to saw off part of the product, drill holes, grooves in it or act in any other mechanical way, as this reduces its load-bearing capacity.

Products for load-bearing walls are manufactured with a thickness equal to or greater than 200 mm. One large lintel can weigh around 100-200 kg, so a lift may be needed for installation. If you need to strengthen the opening in curtain walls, you can use aerated concrete beams with a thickness of 100 to 150 mm. Their weight rarely exceeds 50 kg, so when laying you can do without special equipment.

The only drawback finished products– high cost. Therefore, when searching economical options In order to make lintels over aerated concrete windows, preference is given to less expensive methods.

U-block jumpers

One of the common options is the production of beams in permanent formwork, which are aerated concrete U-blocks grade D500 and higher. This method allows you to obtain a flat outer surface with a continuous masonry pattern and is suitable for strengthening openings up to 3 m.

Device technology

The installation of jumpers from U-blocks is carried out in several stages:

- 1. A strong board is installed at the level of the top line of the masonry and secured with supports so that the aerated concrete lintel does not bend under the weight of the poured concrete. Supports can be made from many materials - wooden blocks, metal pipes, brick columns, etc.

- 2. Tray blocks are laid on the board with the thick wall facing outwards and so that the edges of the structure extend into the masonry by at least 25 cm on each side. The vertical seams and the horizontal segment of the supporting part are glued.

- 3. To insulate the structure, you can put sheets or high-density sheets inside the blocks from the outer wall.

- 4. Also for making lintels over windows in a house made of aerated concrete reinforcement cage. It uses 12-16 mm in diameter, coated with an anti-corrosion compound, knitting and ring wire.

- 5. M200 concrete is mixed and poured inside the structure, compacted and leveled along the upper edge of the blocks. It is important that the mixture covers the reinforcement on all sides.

In some cases, for better load distribution, horizontal reinforcement of the masonry is used in the previous row from where the lintel is installed. You can remove the board, temporary supports and continue construction after the concrete has dried. The timing depends on weather conditions and air temperature.

Monolithic concrete lintels

The method of pouring a monolithic concrete beam is one of the cheapest options for arranging lintels over windows in aerated concrete walls. This method is the most troublesome, but allows you to create a durable structure that can withstand any load well. A serious disadvantage of this method is the fact that the uniformity of the wall surface disappears, which is extremely undesirable when thin-layer plastering of a smooth aerated concrete wall.

The high thermal conductivity of concrete will have to be compensated for by local insulation.

Manufacturing technique

The creation of a monolithic beam is in many ways similar to the construction of lintels from tray blocks, but it also has significant differences. The work is performed in the following order:

- Removable formwork is installed from or sheet materials (plywood, etc.). The structure is strengthened with transverse and vertical bars with a pitch of no more than 50 cm and supports. The formwork is constructed after laying the block row. For it, leave 20-30 cm of space on both sides of the opening.

- Insulation is fixed to the finished formwork on the outer part of the wall. For wet work, expanded polystyrene sheets are most often used.

- Afterwards, a reinforcement frame is made from steel rods. To form the frame, it is better to use ring and knitting wire, but for small houses with a light roof covering, you can use steel reinforcing mesh. It is cut into squares, to which rods are attached with knitting wire.

- Next, the equipped formwork is filled with M200 - M300 mortar to the height of a row of blocks, compacted and leveled.

You can remove the side formwork after the solution has hardened, and it is better to leave the lower horizontal board until it dries completely. In hot weather, it is worth regularly wetting the concrete until it gains the proper strength.

The outer part of the lintel in a house made of aerated concrete will require separate preliminary plastering if the facade is finished with decorative plaster on a block without wall insulation. A layer is applied on top of the insulation, into which an alkali-resistant reinforcing mesh is embedded and leveled.

Corner jumpers

The design using metal corners is the most cost-effective, especially compared to lintels made of aerated concrete. But corners can be used only under certain conditions - the width of the openings is up to 1.2 m with the height of the masonry on top of them being at least 2/3 of this width.

Initially, grooves for corners are cut out in the closing blocks of aerated concrete with an indentation from the edge of the block by 1/3 of its width. Usually the indentation is 10-13 cm. The structure should also rest on the walls. The main rule is to place the corners outside and inside. In this case, metal supports provide the support area necessary for aerated concrete.

For openings up to 1.2 m wide, a corner with a shelf width of 50 mm is sufficient. Steel supports must be treated with an anti-corrosion compound and plastered. To make the plaster stick better, the corners can be wrapped with alkali-resistant or plaster mesh before installation.

Jumpers in small openings

Openings less than 1.2 m wide do not require much reinforcement. Since making a lintel over an aerated concrete window from a reinforced concrete beam is expensive and impractical, you can use the method of reinforcement with steel rods. But this method, like the previous one, is applicable only for cases where the height of the walls on top of the opening is greater than 2/3 of its width. Moreover, we do not recommend using this method for load-bearing walls. To distribute the load, horizontal reinforcement of the masonry on the sides of the opening and in the window sill area is sufficient.

Work technology

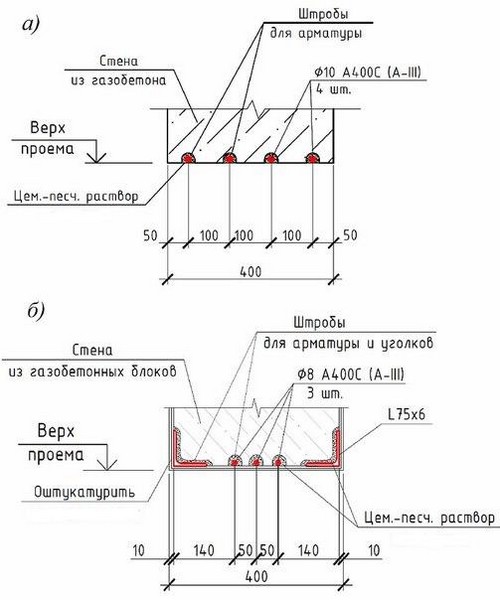

The technology of laying aerated concrete blocks over openings without the use of reinforcing supports (see Fig. a) involves the following sequence of actions:

- A series of blocks are laid out up to the opening. Be sure to leave a space of 20-30 cm for laying reinforcement.

- Unlike laying aerated concrete lintels using U-blocks, the installation of removable formwork is not required.

- Reinforcement is being laid. On average, a door or window opening will require 4 rods with a diameter of 10 mm. Periodic profile rods with pronounced corrugation of class A-III are suitable.

- Grooves are made in the blocks at a certain distance. To do this, it is convenient to use a wall chaser or milling cutter. It is important that the grooves are not too close to the edge.

- The recesses are filled with mortar or glue. The aerated concrete blocks are then installed on fixed steel rods. Vertical joints are closed with mortar or glue.

- If necessary, the lower part of the lintel is sanded and plastered.

The reinforcing bars can withstand the load best if a monolithic stiffening belt is made several rows above them, evenly distributing the weight of the roof over the entire surface of the walls. The small reinforcement area does not create “cold bridges”, so insulation of this segment is not required.

How to make a lintel over a window made of aerated concrete if the expected load on the opening turns out to be slightly greater than the permissible value for steel rods? Alternatively, you can combine the last two methods.

In this case, the 75th corners are recessed into the blocks along the outer and inner edges, and in the central segment grooves are cut for 3 reinforcement rods with a diameter of 8 mm. After fixing the lintel, the corners, pre-painted or treated with an anti-corrosion compound, are plastered.

Conclusion

When choosing what to make lintels from - aerated concrete, reinforced concrete, steel angles or rods - be sure to consider the following factors:

- area and height of the building;

- the weight of the interfloor and attic floors, the roof, the walls themselves;

- material cost;

- construction timeframes.

And remember that if the openings are improperly reinforced, cracks will appear on the walls made of aerated concrete. Conversely, correct calculation, as well as adherence to the technique of making lintels, will allow you to build a durable house without any consequences that may arise in the future.

When building a house from aerated concrete, door and window lintels must be made. There are two options for creating them in aerated concrete houses.

The first is a reinforced concrete lintel. The formwork is assembled and attached directly to the wall. Knitted reinforcement is placed in it and filled with concrete.

It is better to insulate it additionally. If this is not done, a cold bridge will appear.

Advice. Very often, when making reinforced concrete door and window lintels, they are not insulated. This happens because the authors of the project decide to rely on additional insulation. Both external and internal. However, aerated concrete and foam concrete blocks with a width of 400 mm or more are self-sufficient in terms of heat and cold. Plaster will suffice for them to protect them from moisture. But through such cold bridges, cold will flow in, which will cool the hot air rising upward. That is, the more cold bridges there are in a house, the better it cools in winter and heats up in summer.

However, additional insulation may be useful when the width of the blocks is less than 375 mm. For example, you can make a ventilated facade, or simply line the walls decorative bricks at a short distance from aerated concrete.

The second way is to use U-blocks. These are blocks with three walls and a recess in the middle. They are installed in the opening on a wooden support, insulation and knitted reinforcement are laid in them and filled with concrete. When the concrete dries, an independent lintel is obtained. You can remove the tree.

![]()

Monolithic reinforced belt for floors

A monolithic belt in houses made of aerated concrete or foam concrete is required. It performs several functions. Takes on the local load from the floors, which is especially important in houses with reinforced concrete floors. But even in our case with wooden floors, this is important, since there are no weightless structures.

The armored belt must be uniform along its entire length and not be interrupted anywhere. Since it perfectly withstands point loads, which can be detrimental to our blocks, it will not allow them to crack. This can happen, for example, when the roof is not installed completely level and there is pressure on one corner that is stronger than on others. A single monolithic belt will prevent the roof from breaking the aerated concrete.

Advice. Sometimes a situation arises in which a monolithic belt interferes with artistic thought in a house design. For example, you need to make a window on the interfloor landing of the stairs, but an armored belt passes through this place. If there is no seismic activity, if the soils are good or there is a sand cushion, if the house stands on a monolithic foundation, then a gap in the belt can be made. This is one of a series of bad pieces of advice, but in principle it is possible.

The belt will help the walls withstand uneven shrinkage of the soil near the foundation, not crack and maintain a clear vertical position.

Advice. Before building a house, you can walk around your neighbors and look at their houses. As a rule, if the soil in the area is unstable, then small cracks run from the corners of the windows, from the foundation, or simply vertically. If the owner says that the plaster is cracked (and some of his neighbors do too), then you can safely answer him that the problem is in the walls.

Among other things, such a belt is necessary in areas with seismic activity.

Floors

Our house has wooden floors. Firstly, such floors breathe. Secondly, they are light. And thirdly - cheap.

Floors divide the house into floors. In our case, beams were used that connect all the walls in the house. They must rest on both load-bearing and interior walls.

Adviсe. You should start laying beams from the edges of the house. The first beams should be firmly secured, then you can begin laying the rest. The sides and ends of the beams must be impregnated with bioprotective and fire retardant agents. Also, the edges of the beams should be rolled into roofing felt.

Beams are installed on a monolithic reinforced concrete belt. Aerated concrete is laid between them and everything is glued. The beams must be laid perpendicular to the long side of the house. The smaller the span, the larger the overlap can be made (from 60 to 120 cm).

After most of the masonry of aerated concrete walls has been completed, the next stage of construction begins, when it is necessary to make ceilings for door and window openings. The moment comes manufacturing and installation jumpers.

The simplest option is to use ready-made codes jumpers from reinforced aerated concrete. Ready-made lintels are independent load-bearing elements and are designed to cover openings up to 175 cm wide. They are reinforced with a steel frame and do not require additional insulation.

The advantage of installing ready-made lintels is, of course, the speed and resulting in a smooth, uniform and even surface of the wall, which facilitates plastering work. The disadvantage of ready-made aerated concrete lintels is their unreasonably high price.

Jumpers made of U-blocks

|

The second option is to manufacture lintels directly on the construction site using so-called U-shaped blocks (tray blocks). |

|

U-blocks are laid on the prepared mounting base. It can be done using a board and timber. The base for the lintel must be strong enough and should not bend when concrete is poured into the assembled structure. To do this, the base of the board should be supported, for example, with racks, especially in cases with wide openings. |

| On the platform made in this way, the U-blocks are placed end-to-end, and the vertical seams between them are filled with a thin layer of adhesive solution. | |

|

Insulation should be placed inside the U-blocks, closer to the outside (a sheet of foam plastic or mineral wool), since the wall thickness of U-blocks is 60 mm and is not enough to insulate a concrete monolith. |

|

Next, a reinforcement frame is installed inside the lintel. The frame consists of four reinforcement bars, fastened together in cross section, with a cell pitch of 100 mm 150 mm. It is recommended to use rod reinforcement with a diameter of 12 mm for jumpers, wire with a diameter of 6 mm for ring tying, and knitting wire to fasten the frame. |

|

Concrete is poured into the lintel cavity, which must be compacted and leveled. The recommended grade of concrete is no less than M200, i.e. standard foundation concrete. |

The use of U-blocks greatly simplifies the process of making lintels, and the resulting floors have good load-bearing capacity. Perhaps the only drawback of tray blocks, as in the case of ready-made lintels, is their price. On average, the cost of one U-block is $10.

Jumpers using metal corners

Third manufacturing method jumpers for openings in walls made of aerated concrete, consists of laying blocks on lintels made of metal corners.

The bearing capacity of the corner is sufficient to support one row of aerated concrete blocks laid on glue. Aerated concrete blocks are placed end to end, and the ends of the vertical joints are filled with a thin layer of adhesive mortar.

After the glue has hardened, the resulting lintel is a structure made of monolithic aerated concrete, which has a strength no lower than that of an aerated concrete block. After installing the windows, the part of the metal corner located on the outside must be insulated (with foam plastic or mineral wool) and plastered.

The disadvantage of this method is that if the corners are inserted incorrectly and their outer parts are not properly insulated, condensation may appear on the slopes indoors.

Monolithic concrete lintels

The fourth method used in cannot be called completely simple, but it is reliable and quite inexpensive compared to using ready-made aerated concrete lintels and U – blocks. It consists of manufacturing by concreting with reinforcement and simultaneous insulation of lintels in wooden formwork made above the opening. This method resembles the second option, only there U - blocks performed the function permanent formwork.

|

To do this, after laying the blocks, it is necessary to erect wooden formwork to the border of the support zone of the future lintel (250 mm or 300 mm from the window opening), using boards, timber and OSB (or laminated plywood). 100 mm insulation is inserted inside from the outside. On the inside, the insulation is coated with an adhesive solution for better adhesion to the concrete. A frame of reinforcement is installed inside the formwork, everything is the same as in the case of U-blocks. |

|

The next step is to fill the formwork with concrete to a level equal to the height of the block, that is, 200 mm. |

|

After the concrete has hardened, the formwork is removed and as a result we get a reinforced concrete lintel insulated from the outside. |

|

The insulated outer part of the lintel must be reinforced and plastered using alkali-resistant facade mesh. |

The last manufacturing method given jumpers for openings in walls made of aerated concrete, is the most appropriate from an economic and constructive point of view. This option will be much cheaper than the first two, but more expensive than the method using corners. But we will get a full-fledged reinforced lintel, which will never give rise to cracks.

In the following articles, read about how to make

Many inexperienced builders use reinforced concrete lintels when constructing wall openings. However, modern manufacturers offer a more practical option. The use of jumpers for aerated concrete blocks allows such work to be carried out much faster, and also not to damage appearance opening. In addition, the use of such material increases the thermal insulation of the box. All the subtleties of using aerated concrete are worth considering in more detail.

What is it used for?

The aerated concrete masonry above the opening is subject to serious pressure. High loads affect it not only during the construction of the house, but also during its operation. To evenly distribute the load on the opening, reinforcing bars should be installed using a wall chaser. After placing the reinforcement in the groove, it is sealed with mortar.

How to choose the type of lintel for a door or window opening? To make the right decision, you should take into account indicators such as the availability of material and the length of the span to be covered.

Features of installation of different designs

Openings that are quite long can be covered with monolithic reinforced concrete products. If the length of the opening does not exceed 3 m, reinforced concrete beams placed in permanent formwork should be used. If the opening in the aerated concrete wall is only 1.2 m long, there is no need to make a lintel. This condition is met in cases where the masonry above the opening has a height of no more than 2/3 of the width of the opening itself.

Piers in load-bearing structure must have a width of at least 60 cm. If it is necessary to make a partition of smaller width, it should be built of brick. For such piers can be used aerated concrete blocks with reinforcement.

A more optimal solution for maintaining the thermal insulation of the external walls of a house is to create lintels that are made of aerated concrete. They are installed above window and door openings. Such blocks usually have a density grade of D700. For this purpose, monolithic products in permanent formwork, which is represented by U-blocks, can also be used. The latter have a density of D500.

Sometimes reinforcing lintels is the simplest procedure, thanks to which you can cover an opening no larger than 174 cm. When choosing lintels, you should take into account their weight. Monolithic reinforced concrete products are very heavily loaded load-bearing walls. To install such structures, you will need to use lifting equipment. To lay reinforced aerated concrete structures on masonry, there is no need to create special unloading areas.

The lintels made above the openings are usually 2 cm long. The wall of the U-block, which is thicker, faces the street. The assembly of permanent formwork from such blocks is carried out on a temporary support. After the solution has completely hardened, it is removed.

Monolithic products

When using monolithic reinforced concrete lintels, it is possible to block openings up to 3 m wide. Such structures are second only to ceilings made of heavy concrete. U-shaped reinforced concrete products are installed without the use of special equipment. This circumstance is a significant advantage.

However, this technology requires good preparation and a fairly large amount of work during which the jumper will be created. The product is equipped with a metal frame in U-shaped blocks. If they are 20 cm wide and the tray is 12 cm wide, it is permissible to reinforce them with 2 reinforcing bars. All blocks that have a tray width greater than 15 cm must be reinforced using 4 rods.

Openings can be constructed without lintels if several mandatory requirements are met. One of them has already been mentioned above - the masonry above the opening should be no more than 2/3 of the width of the opening. To create rows of masonry with such an opening, it is necessary to use temporary formwork. During work, aerated concrete adhesive is used.

At insufficient height The masonry should be reinforced with an ordinary non-load-bearing retaining structure. Steel angles can also be used. When using them, several subtleties must be taken into account:

- Steel corners can be stained with rust. They are coated with paint both inside and outside.

- The support on the masonry has a minimum length of 20 cm.

- It is better if the corners are fastened with steel tape. A wire tie is used for this. Welding can be used to fasten the tape.

- The corners are usually recessed into aerated concrete. They should not protrude from the wall.

- Steel corners must be wrapped with plaster mesh if the walls are subsequently plastered.

When creating a monolithic jumper, you will need to perform the following steps:

- It is necessary to combine reinforced structures using lifting equipment. The jumper is installed with the arrow pointing up. It is better to make the support with a depth of 25 cm. It is optimal if it is 30 cm. The width should be equal to the width of the block.

- The jumpers must be fastened together. The element should not be deformed. It should not be shortened or made into the hole element. Violation of the integrity of the structure will lead to loss of its strength.

- The next jumper is laid close to the previous one.

- The surface of the structures is leveled with a plane.

- The mixture for thin joint masonry is expected to set.

When performing such actions, you can design a door or window opening with your own hands. The support of the lintels on the walls should be as reliable as possible. This can be ensured by performing correct calculations.

Origin and character of the name Victor Profession and business

Origin and character of the name Victor Profession and business How can you replace unusual recipe ingredients, mascarpone, balsamic vinegar, alcohol and even eggs Cake made from M&M's and KitKat

How can you replace unusual recipe ingredients, mascarpone, balsamic vinegar, alcohol and even eggs Cake made from M&M's and KitKat How to properly set the table for Christmas?

How to properly set the table for Christmas?